Spring Roll Machine Fully Automatic Supplier

About spring roll machine fully automatic supplier

Where to Find Spring Roll Machine Fully Automatic Suppliers?

China leads global production of fully automatic spring roll machines, with key manufacturing clusters in Henan and Hebei provinces. These regions host specialized food machinery ecosystems that integrate R&D, precision engineering, and automated assembly lines. Henan, in particular, is home to over 70% of China’s snack food processing equipment suppliers, offering scalable production capacity supported by mature supply chains for stainless steel components, food-grade conveyor systems, and PLC control units.

The industrial zones around Langfang and Zhengzhou provide logistical advantages, enabling efficient export via Tianjin and Qingdao ports. Suppliers benefit from vertically integrated operations—many maintain in-house CNC machining, welding, and automation programming divisions—reducing component lead times by up to 40%. Buyers can expect standard delivery windows of 25–40 days for fully assembled systems, with cost efficiencies averaging 25–35% compared to European or North American manufacturers due to localized sourcing and lower labor costs.

How to Choose Spring Roll Machine Fully Automatic Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

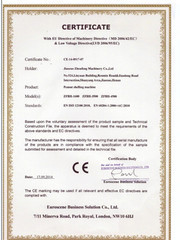

Confirm adherence to international food safety standards. Equipment should be constructed from SUS304 or SUS316 stainless steel and comply with CE marking requirements for electrical safety and machinery directives. Request documentation on PLC brands (e.g., Siemens, Delta), motor specifications (IP65 rating recommended), and validation reports for hygiene design. Machines must support washdown environments and avoid material contact with non-food-grade lubricants or coatings.

Production Capacity Verification

Assess infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² for full-line production

- In-house engineering teams capable of customizing mold dies, filling mechanisms, and output speeds

- Monthly production capacity of at least 30 units per model for inventory stability

Cross-reference online revenue indicators and reorder rates: suppliers with >20% repeat order ratios typically demonstrate consistent quality and after-sales service.

Customization & Quality Assurance

Evaluate customization depth beyond basic voltage adjustments. Leading suppliers offer configurable parameters including roll diameter (60–150mm), thickness control (0.8–3mm), output speed (up to 3,000 pcs/hour), and integration with downstream frying or packaging lines. Demand video evidence of machine operation under load and request sample production runs. Prioritize partners providing third-party inspection options prior to shipment.

What Are the Best Spring Roll Machine Fully Automatic Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Langfang Shengxing Food Machinery Co., Ltd. | Hebei, CN | Food Processing Lines, Bread Making Machines | Not Disclosed | 100% | ≤4h | Not Available | 5 models | $58,000–$240,000 |

| Saidashi Machinery (Henan) Co., Ltd. | Henan, CN | Grain Product Making Machines, Vegetable Cutters | US $100,000+ | 100% | ≤3h | 20% | 5 models | $1,290–$2,200 |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Henan, CN | Customizable Dumpling & Samosa Machines | US $130,000+ | 100% | ≤2h | <15% | 5 models | $550–$2,000 |

| Zhengzhou Hento Machinery Co., Ltd. | Henan, CN | Spring Roll Wrapper Machines, Coil Systems | US $360,000+ | 100% | ≤1h | 20% | 5 models | $948–$8,990 |

| Qixian Xincheng E-Commerce Co., Ltd. | Henan, CN | Vegetable Cutters, Momo Skin Machines | US $4,000+ | 100% | ≤1h | <15% | 5 models | $225–$531/kg or per dozen |

Performance Analysis

Langfang Shengxing represents the high-end segment, offering complete lumpia production lines priced above $58,000, suitable for large-scale commercial bakeries and frozen food processors requiring turnkey automation. In contrast, mid-tier suppliers like Saidashi Machinery and Jiaozuo Dingchang deliver competitively priced systems ($1,290–$2,000) with modular designs adaptable to samosa, gyoza, or tortilla sheet production. Zhengzhou Hento stands out with the highest recorded online revenue and rapid response times, indicating robust customer engagement and market penetration.

Notably, all top suppliers guarantee 100% on-time delivery, a critical factor for time-sensitive capital investments. However, reorder rates vary significantly—companies with 20%+ retention (Saidashi, Hento) likely provide superior technical support and spare parts availability. Buyers seeking budget-friendly entry-level automation may consider Qixian Xincheng, though its pricing model (per kg or dozen) suggests focus on smaller components rather than full machines.

FAQs

What certifications should spring roll machine suppliers have?

Essential certifications include CE for EU compliance and ISO 9001 for quality management. While not always present in listings, suppliers should be able to provide test reports for electrical safety, noise levels, and material corrosion resistance upon request.

What is the typical MOQ and lead time?

Minimum Order Quantity is generally 1 set for fully assembled machines. Lead times range from 20–40 days depending on customization level. Simple configurations ship within 3 weeks; complex integrations with conveyors or fryers may require 6–8 weeks.

Can suppliers customize machine output capacity?

Yes, most established suppliers allow adjustments to output speed, roll size, and filling mechanisms. Custom molds and multi-lane setups are available for high-volume producers, often requiring CAD drawings or physical samples for replication.

Do suppliers offer installation and training?

Many provide remote guidance via video tutorials and manuals. On-site commissioning services are occasionally offered but usually incur additional fees. Clarify support terms during negotiation, especially for first-time buyers.

How are machines packaged for international shipping?

Machines are typically crated in seaworthy wooden cases with anti-rust treatment and shock-absorbing materials. FOB terms are common; buyers should confirm whether disassembly/palletization is included and verify insurance coverage for transit damage.