Spring Roll Wrap Machine Supplier

1/20

1/20

1/15

1/15

1/14

1/14

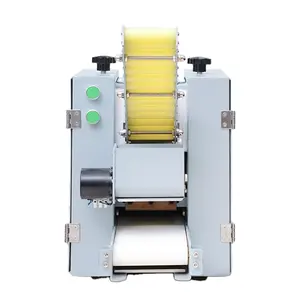

About spring roll wrap machine supplier

Where to Find Spring Roll Wrap Machine Suppliers?

China remains the central hub for spring roll wrap machine manufacturing, with key industrial clusters in Henan and Hebei provinces driving production efficiency and export volume. Zhengzhou in Henan has emerged as a core center for food processing machinery, hosting numerous integrated suppliers specializing in grain product equipment and automated snack-making systems. Langfang in Hebei complements this ecosystem with advanced fabrication capabilities focused on full-line food processing solutions.

These regional hubs benefit from vertically aligned supply chains—encompassing steel forming, CNC machining, and electrical integration—within compact geographic zones, reducing component lead times by up to 40%. The proximity of technical engineers, parts vendors, and logistics providers enables rapid prototyping and scalable output. Buyers can expect standard lead times of 25–40 days for machine delivery, with localized sourcing cutting production costs by 18–25% compared to equivalent suppliers outside Asia. Export infrastructure is well-developed, supporting containerized shipments to North America, Europe, Africa, and Southeast Asia via major ports like Qingdao and Tianjin.

How to Choose Spring Roll Wrap Machine Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international safety and performance standards. CE certification is essential for market access in Europe and many emerging economies, validating electrical safety and mechanical reliability. While ISO 9001 registration is not universally listed, prioritize suppliers who reference formal quality management systems. Request test reports or video demonstrations of machine operation under continuous load conditions.

Production Capacity Assessment

Evaluate supplier capability through objective metrics:

- Facility size and automation level (e.g., fully automatic vs. semi-automatic assembly lines)

- In-house engineering support for customization (e.g., mold design, material feed adjustments)

- Integration of core technologies such as temperature-controlled rollers, precision thickness regulation, and servo-driven feeding systems

Cross-reference online revenue indicators and order fulfillment rates to assess scalability and operational stability.

Customization & Transaction Security

Many suppliers offer configurable options including diameter range (100–600mm), sheet thickness (0.2–2mm), output speed (60–200 pcs/min), and material compatibility (rice flour, wheat-based dough, gluten-free blends). Verify available customization parameters before finalizing specifications. Use secure payment mechanisms such as escrow services to mitigate risk, particularly when engaging newer or lesser-documented manufacturers. Insist on pre-shipment inspection rights and sample validation prior to bulk orders.

What Are the Best Spring Roll Wrap Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Himore Machinery Equipment Co., Ltd. | Henan, CN | Grain Product Making Machines, Snack Machines | $1,500–1,800 | 1 set | 100% | ≤3h | US $1,000+ | <15% |

| Henan H&d Industrial Co., Ltd. | Henan, CN | Grain Product Making Machines, Flour Mill | $350–4,200 | 1 set | 100% | ≤1h | US $40,000+ | 25% |

| Langfang Shengxing Food Machinery Co., Ltd. | Hebei, CN | Food Processing Lines, Bread Making Machines | $15,000–240,000 | 1 set | 100% | ≤4h | Not specified | - |

| Jiaozuo Taoding Trading Co., Ltd. | Henan, CN | Customizable Pancake & Wrapper Machines | $1,400–2,000 | 1 set | 97% | ≤2h | US $560,000+ | <15% |

| Qixian Xincheng E-Commerce Co., Ltd. | Henan, CN | Dumpling & Spring Roll Skin Machines | $225–530/kg or per dozen | 1 kg / 1 dozen | 100% | ≤1h | US $4,000+ | <15% |

Performance Analysis

Suppliers vary significantly in scale and specialization. Langfang Shengxing targets high-capacity industrial clients with premium-priced, CE-certified全自动生产线 (fully automatic production lines), indicating focus on turnkey factory installations. In contrast, Zhengzhou Himore and Jiaozuo Taoding serve mid-tier commercial buyers with competitively priced machines ($1,400–2,000 range), backed by strong online sales volumes and responsive communication.

Henan H&d stands out for balancing affordability with higher reorder activity (25%), suggesting customer satisfaction in niche applications such as samosa and injera sheet production. Qixian Xincheng operates on a unique pricing model—offering components by weight or dozens—catering to spare part replacements or small-scale upgrades rather than full-system procurement.

Buyers seeking cost-effective entry-level machines should prioritize suppliers offering sub-$2,000 units with proven delivery records. For large-scale deployment, focus on manufacturers with documented system integration experience and robust after-sales service channels.

FAQs

How to verify spring roll wrap machine supplier reliability?

Validate compliance documentation (CE, if claimed), request facility videos demonstrating active production, and analyze response consistency. Check historical transaction data where available, focusing on on-time delivery rates above 97% and verified post-purchase feedback related to durability and technical support.

What is the typical MOQ and pricing structure?

Most suppliers list a minimum order quantity of 1 set for complete machines. Pricing ranges from $1,400 for basic models to over $200,000 for fully automated, multi-lane systems. Some vendors quote per kilogram or per dozen for replacement molds or modular components rather than full units.

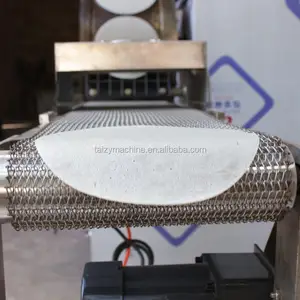

Can these machines be customized for specific dough types?

Yes, several suppliers explicitly support customization for rice paper, lumpia, samosa, injera, and pancake-style sheets. Adjustments include roller texture, heating profile, feed rate, and sheet dimension controls. Confirm material compatibility and request sample outputs before placing volume orders.

Do suppliers provide technical support and installation guidance?

While not always formally stated, leading suppliers typically offer remote assistance via video calls or manuals. High-end systems may include commissioning support or training sessions. Clarify service scope—including spare parts availability and warranty terms—prior to purchase.

What are the common packaging and shipping methods?

Machines are generally crated in wooden cases suitable for sea freight. Most suppliers accommodate FOB, CIF, or DDP terms. Air freight is viable for single units or urgent deliveries, though it increases transport costs by 3–5x compared to ocean shipping.