Stairwell Scaffolding

1/2

1/2

1/3

1/3

1/22

1/22

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

CN

CN

1/22

1/22

1/20

1/20

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

CN

CN

1/22

1/22

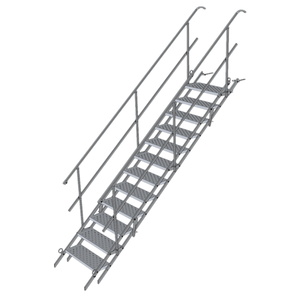

About stairwell scaffolding

Where to Find Stairwell Scaffolding Suppliers?

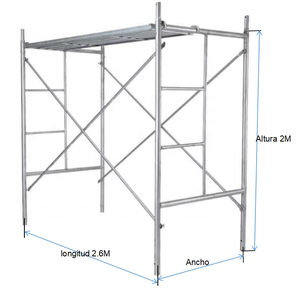

China's stairwell scaffolding manufacturing sector is characterized by regional specialization and vertically integrated production networks, with key suppliers concentrated in Guangdong and Tianjin. These regions host industrial clusters that combine advanced metal fabrication capabilities with streamlined export logistics. Guangdong-based manufacturers leverage proximity to Shenzhen and Guangzhou ports, enabling faster container dispatches—typically within 7–10 days of order confirmation. Tianjin’s suppliers benefit from access to high-grade steel mills in Hebei, reducing raw material lead times by up to 25% compared to inland facilities.

Suppliers in these zones operate within mature supply ecosystems, integrating aluminum extrusion, powder coating, CNC cutting, and modular assembly under single rooftops. This vertical integration supports rapid prototyping and scalable batch production, with standard lead times averaging 20–35 days for containerized orders. Buyers gain access to cost efficiencies driven by localized sourcing, where production costs are 18–30% lower than in EU- or North America-based fabricators. The presence of certified welding teams and in-house quality control labs further enhances consistency across large-volume runs.

How to Choose Stairwell Scaffolding Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional parameters:

Material & Structural Compliance

Confirm use of load-rated materials such as Q235/Q355 steel or 6061-T6 aluminum alloy, compliant with EN 12811 or OSHA standards. Request mill test certificates (MTCs) for structural components and verify wall thickness tolerances (±0.2mm). For aluminum systems, ensure anodizing or powder coating meets ASTM B117 for corrosion resistance.

Production Capacity Verification

Assess infrastructure maturity through objective indicators:

- Minimum monthly output capacity exceeding 500 sets

- In-house welding, punching, and surface treatment lines

- Dedicated R&D units for custom configurations

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours) as proxies for operational efficiency.

Transaction Risk Mitigation

Prioritize suppliers offering third-party inspection options (e.g., SGS, BV) and secure payment terms via trade assurance mechanisms. Conduct virtual factory audits to validate equipment calibration logs and finished product testing protocols. Sample validation is critical—request load tests simulating 4x working limits before full-scale ordering.

What Are the Best Stairwell Scaffolding Suppliers?

| Company Name | Location | Main Materials | Min. Order Qty | Price Range (USD) | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Jinisi Metal Products Co., Ltd. | Guangdong, CN | Aluminum Alloy, Steel | 2 sets | $3–1,039 | 100.0% | ≤1h | $10,000+ | <15% |

| Tianjin Zhenxiangyude International Trading Co., Ltd. | Tianjin, CN | Q235/Q355 Steel | 100 pieces | $2.90–600 | 100.0% | ≤2h | $50,000+ | 50% |

| Beijing Zulin Formwork And Scaffolding Co., Ltd. | Beijing, CN | Steel, Ringlock System | 30 meters | $135–2,585 | 100.0% | ≤4h | $220,000+ | <15% |

| Shenzhen Forestar Industry Co., Ltd. | Guangdong, CN | Aluminum Alloy | 1 set | $20–180 | 100.0% | ≤2h | $20,000+ | <15% |

| Shenzhen Prima Industry Co., Ltd. | Guangdong, CN | Stainless Steel | 2 sets | $599–1,000 | 100.0% | ≤2h | $100+ | 33% |

Performance Analysis

Tianjin Zhenxiangyude stands out with a 50% reorder rate, indicating strong customer satisfaction despite higher MOQs, likely due to competitive pricing for heavy-duty steel systems. Beijing Zulin demonstrates engineering specialization in PERI-compatible and ringlock stairwell solutions, catering to large-scale construction projects requiring modular integration. Guangzhou Jinisi and Shenzhen Forestar offer low MOQs (as low as 1–2 sets), making them suitable for small contractors or pilot procurement. Shenzhen Prima differentiates through stainless steel construction, ideal for corrosive environments, though at a premium price point. All listed suppliers maintain 100% on-time delivery records, signaling robust production planning and export coordination.

FAQs

How to verify stairwell scaffolding supplier reliability?

Validate certifications through official registries and request evidence of product testing under EN 1004 or ANSI A10.8 standards. Conduct video audits of welding and assembly lines, and review documented QC procedures including load testing and dimensional inspection reports.

What is the typical minimum order quantity?

MOQs range from 1 set for aluminum mobile units to 100 pieces or 10 tons for steel components. Suppliers like Guangzhou Jinisi accommodate trial orders, while steel tube producers often require tonnage-based commitments to justify production runs.

Can suppliers customize stairwell scaffolding dimensions?

Yes, most suppliers offer customization in height (2–10m), tread width (0.6–1.2m), and material finish. Custom color coding, non-slip coatings, and foldable designs are available upon request, typically extending lead time by 5–10 days.

Do manufacturers provide load testing documentation?

Reputable suppliers issue internal load test reports showing performance at 4x the working load limit. Third-party verification (SGS/BV) can be arranged for an additional fee, usually 1.5–3% of order value.

What are the common packaging and shipping methods?

Scaffolding is typically flat-packed with corner protectors and moisture-resistant wrapping. Full-container loads (20ft or 40ft HC) are standard; air freight is viable only for sample units due to weight constraints. FOB terms are most common, but CIF can be negotiated for bulk shipments.