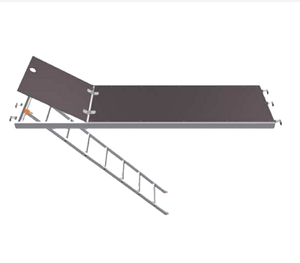

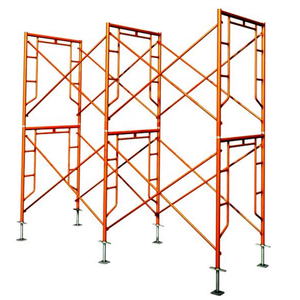

Scaffolding Platform

Top sponsor listing

Top sponsor listing

1/14

1/14

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/10

1/10

0

0

1/24

1/24

1/8

1/8

0

0

1/34

1/34

1/22

1/22

1/13

1/13

1/15

1/15

1/14

1/14

1/3

1/3

1/7

1/7

About scaffolding platform

Where to Find Scaffolding Platform Suppliers?

China remains the global hub for scaffolding platform manufacturing, with key production clusters concentrated in Jiangsu, Jiangxi, and Shandong provinces. These regions host vertically integrated supply chains that combine structural steel fabrication, powder coating, and electrical integration under one ecosystem. Yangzhou and Qingdao serve as primary export centers due to proximity to major ports, enabling efficient containerized shipments to international markets. The industrial base benefits from localized access to Q235 and Q345-grade steel, reducing material procurement lead times by 10–15 days compared to offshore alternatives.

Suppliers in these zones operate high-efficiency production lines capable of welding, folding, and surface treatment in sequence, supporting monthly outputs ranging from 200 to 1,000 units depending on model complexity. Integrated logistics networks allow direct rail-to-port movement, minimizing inland freight costs. Buyers gain access to scalable production capacity, with average lead times for standard orders between 25 and 40 days. Cost advantages are significant—localized processing reduces unit prices by 20–35% versus EU or North American manufacturers, particularly for electric and foldable models requiring CNC-formed components.

How to Choose Scaffolding Platform Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards for quality management systems. For export to regulated markets, CE certification is essential for compliance with EU Machinery Directive 2006/42/EC. Validate test reports for load-bearing performance (e.g., 1.5x rated capacity testing), electrical safety (IP ratings for motor enclosures), and structural integrity (deflection tests under maximum load).

Production Capacity Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to support batch assembly

- In-house capabilities in robotic welding, hydraulic pressing, and powder coating

- Dedicated R&D teams for custom engineering of height, width, and lifting mechanism

Cross-reference online revenue metrics and on-time delivery rates (target ≥97%) to assess operational stability and order fulfillment reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only upon inspection clearance. Prioritize suppliers with documented customization workflows—including 3D modeling and prototype validation—for non-standard configurations. Conduct virtual audits via facility videos to verify production line automation and inventory management practices before committing to volume orders.

What Are the Best Scaffolding Platform Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Yangzhou Longtai Machinery Equipment Co., Ltd. | Jiangsu, CN | Scaffoldings (109), Work Platforms (49) | $80,000+ | 100% | ≤5h | <15% | Color, material, size, logo, packaging, graphic |

| Jiangxi Mide Industrial Co., Ltd. | Jiangxi, CN | Multiple Models, Explosion-Proof Variants | $380,000+ | 97% | ≤3h | <15% | Capacity, height, color, material, width, labeling |

| Deans Join Heavy Industry Co., Ltd. | Hubei, CN | Hoists (266), Bridge Cranes (208) | $10,000+ | 100% | ≤3h | <15% | Foldable, remote-controlled, multi-mode operation |

| Xingtai Sujin Machinery Manufacturing Co., Ltd. | Hebei, CN | Portable Electric Models (3–8m) | $100,000+ | 100% | ≤4h | 25% | Foldable, mobile, new-design variants |

| Qingdao Runze Intelligent Equipment Co., Ltd. | Shandong, CN | Folding Units (4m–10m), 300–500kg Capacity | $7,000+ | 100% | ≤3h | <15% | Height, load rating, modular folding design |

Performance Analysis

Jiangxi Mide leads in revenue volume and response speed, indicating strong market demand and customer engagement, though its slightly lower on-time delivery rate warrants closer logistics scrutiny. Yangzhou Longtai and Xingtai Sujin demonstrate consistent delivery performance (100%) with diversified product portfolios tailored to construction and industrial maintenance sectors. Deans Join leverages crane-system expertise to offer advanced electric scaffolding platforms with remote control functionality, appealing to precision-focused applications. Qingdao Runze specializes in compact, high-mobility units ideal for indoor use. Suppliers with reorder rates below 15% suggest standardized offerings with limited after-sales dependency, whereas Xingtai Sujin’s 25% repeat rate may indicate higher service engagement or niche product differentiation.

FAQs

How to verify scaffolding platform supplier reliability?

Cross-check certifications (ISO, CE) through official registries. Request factory audit reports detailing welding procedures, non-destructive testing protocols, and final assembly inspections. Analyze customer feedback focusing on structural durability, motor reliability, and ease of folding/unfolding mechanisms.

What is the typical MOQ and lead time?

Most suppliers offer a minimum order quantity of 1 unit, facilitating sample validation. Standard lead times range from 25 to 40 days post-deposit, depending on customization level. Foldable electric models with imported drive systems may require an additional 7–10 days.

Can scaffolding platforms be customized?

Yes, common customization parameters include working height (3m–10m), load capacity (300kg–1,500kg), frame color, control interface (remote/wired), and power source (AC/DC). Suppliers typically provide CAD drawings within 48 hours and functional prototypes in 3–4 weeks.

Do suppliers support global shipping?

All listed suppliers have export experience, with FOB terms standard. Confirm packaging specifications (wooden crate vs. flat-pack) and compatibility with 20ft/40ft containers. Sea freight is optimal for bulk orders; air shipment is viable for single units needing rapid deployment.

Are samples available for testing?

Sample availability depends on model. Basic folding units may be provided at cost (typically $150–$550), with fees offset against future bulk orders. Custom-configured platforms require full payment for initial units due to non-reusable tooling costs.