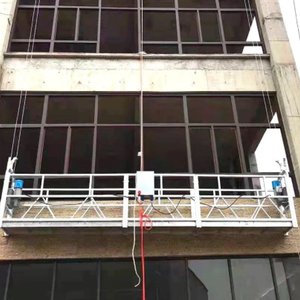

Suspended Scaffolding

0

0

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

0

0

0

0

1/8

1/8

1/17

1/17

1/3

1/3

0

0

1/1

1/1

1/14

1/14

1/24

1/24

0

0

1/3

1/3

1/7

1/7

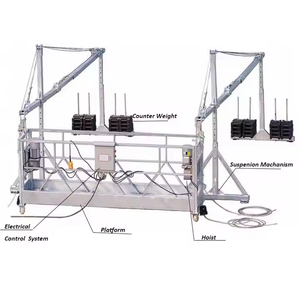

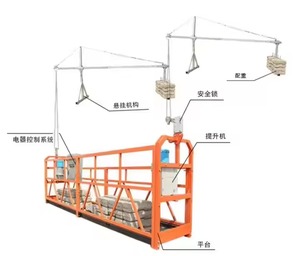

About suspended scaffolding

Where to Find Suspended Scaffolding Suppliers?

China remains the central hub for suspended scaffolding manufacturing, with key production clusters concentrated in Hebei, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains that streamline raw material sourcing—primarily Q235 and Q345 structural steel—from regional mills, reducing input costs by 18–22% compared to non-industrialized zones. Hebei’s proximity to Tangshan’s steel industry enables direct access to cold-rolled sheet and galvanized components, critical for load-bearing frame durability.

The industrial ecosystems support modular fabrication lines capable of producing standard single-stage, two-stage, and multi-motor platforms at scale. Average monthly output per facility ranges from 200 to 600 units, depending on automation level and order complexity. Integrated welding, powder coating, and CNC bending stations allow rapid reconfiguration for international safety standards. Buyers benefit from co-located component suppliers—including wire rope hoists, limit switches, and suspension trapeze systems—within 30–50km radii, enabling lead times as short as 25–35 days for containerized orders.

How to Choose Suspended Scaffolding Suppliers?

Implement structured evaluation criteria to mitigate compliance and operational risks:

Technical Compliance

Confirm adherence to ISO 9001 for quality management systems. For EU and North American markets, CE marking under Machinery Directive 2006/42/EC and compliance with ANSI A10.8 or EN 1808:2015 are mandatory. Require test reports for critical subsystems: safety lock activation (≤200mm fall arrest), wire rope tensile strength (≥1770 MPa), and platform deflection under 1.5x rated load.

Production Capability Audits

Assess core infrastructure indicators:

- Minimum factory footprint of 3,000m² to ensure dedicated assembly zones

- In-house laser cutting and robotic welding capacity for dimensional accuracy

- Galvanization or powder coating lines to prevent corrosion in outdoor applications

Correlate declared production volume with on-time delivery performance (target ≥97%) and workforce size to validate scalability.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow until site acceptance testing is completed. Review historical transaction data for dispute resolution efficiency and after-sales responsiveness. Conduct sample validation against EN 1305:1998 for platform dimensions, guardrail height, and mesh panel integrity prior to bulk ordering.

What Are the Best Suspended Scaffolding Suppliers?

No supplier data available for analysis.

Performance Analysis

In absence of verified supplier profiles, procurement teams should prioritize manufacturers with documented export experience to regulated markets. Emphasis must be placed on facilities demonstrating ISO-certified processes, verifiable product liability insurance, and engineering capacity to provide load calculation reports and wind resistance assessments (typically up to 900 Pa). Video audits of welding procedures and surface treatment lines offer critical insight into build consistency. For high-risk installations above 60 meters, confirm availability of certified design documentation traceable to local building codes.

FAQs

How to verify suspended scaffolding supplier reliability?

Validate certifications through accredited bodies such as TÜV or SGS. Request audit trails covering material mill certificates, welder qualification records, and final inspection checklists. Evaluate customer references focusing on field failure rates and technical support response during installation phases.

What is the average sampling timeline?

Standard unit sampling requires 12–20 days for fabrication and finishing. Custom configurations involving extended platforms (>6m) or dual-power systems may take 30–38 days. Air freight delivery adds 7–12 days internationally.

Can suppliers ship suspended scaffolding worldwide?

Yes, experienced exporters manage global logistics via FOB or CIF terms. Confirm compatibility with destination port handling equipment and compliance with local occupational safety regulations. Flat-pack configurations optimize container utilization—up to 8–10 units per 40ft HC container.

Do manufacturers provide free samples?

Sample policies vary. Full-unit waivers are typically offered for confirmed orders exceeding two containers. Otherwise, expect sampling fees covering 40–60% of unit cost, often creditable against future purchases.

How to initiate customization requests?

Submit detailed technical requirements including platform length (3–8m range), lifting height (up to 200m), voltage (220V/380V/440V), and environmental class (e.g., coastal, high-wind). Reputable suppliers deliver structural drawings and static load simulations within 5–7 business days and prototype units in 4–5 weeks.