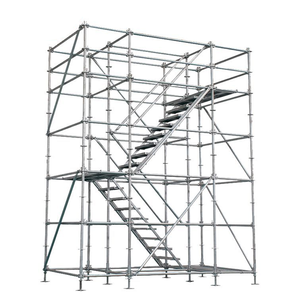

Cantilever Scaffolding

1/9

1/9

1/3

1/3

1/20

1/20

1/16

1/16

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/10

1/10

1/22

1/22

1/2

1/2

1/3

1/3

1/16

1/16

1/3

1/3

1/25

1/25

1/34

1/34

About cantilever scaffolding

Where to Find Cantilever Scaffolding Suppliers?

China remains a dominant force in the global cantilever scaffolding supply chain, with key manufacturing clusters concentrated in Tianjin, Suzhou, and Sichuan. These regions host vertically integrated metal fabrication facilities specializing in structural steel systems for high-rise construction. Tianjin's industrial base leverages proximity to port infrastructure and abundant Q235 steel sourcing, enabling cost-efficient production of load-bearing components. Suzhou-based suppliers integrate advanced powder coating and modular design capabilities, catering to precision-focused markets in Europe and Australia. Sichuan’s emerging smart manufacturing initiatives support automated welding lines, enhancing consistency in large-volume orders.

The regional ecosystems offer scalability through consolidated access to raw materials, CNC processing, galvanization, and logistics. Suppliers in these zones typically maintain in-house engineering teams capable of adapting standard systems—such as ringlock, cuplock, and quickstage—to cantilever configurations. Buyers benefit from lead times averaging 20–35 days for batch production, with localized supply chains reducing material costs by 15–25% compared to Western fabricators. The presence of ISO-certified workshops and third-party inspection readiness further strengthens export compliance.

How to Choose Cantilever Scaffolding Suppliers?

Effective supplier evaluation requires systematic assessment across technical, operational, and transactional dimensions:

Structural Compliance & Certification

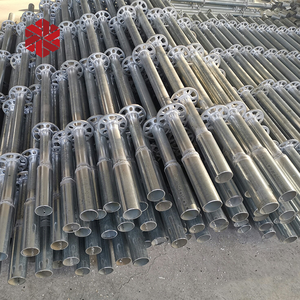

Confirm adherence to international safety standards such as EN 12811 (scaffolding design) or AS/NZS 1576. Verify use of high-tensile Q235 or Q345 steel and hot-dip galvanization (HDG) for corrosion resistance. Request test reports on weld integrity, load capacity (typically 2–5 kN/m²), and dimensional accuracy. CE marking is essential for European market entry.

Production Capacity Verification

Assess core manufacturing capabilities:

- Minimum factory area exceeding 3,000m² for sustained output

- In-house cutting, welding, drilling, and surface treatment lines

- Monthly production capacity above 500 sets for scalable fulfillment

Cross-reference declared capacities with order history and on-time delivery performance (target ≥95%).

Customization & Quality Control

Evaluate flexibility in modifying platform length, bracket angle, connection type, and finish. Prioritize suppliers offering CAD-based design validation and pre-shipment inspections. Look for documented QC protocols covering raw material inspection, in-process checks, and final assembly audits. Reorder rates above 30% may indicate strong product reliability and service alignment.

What Are the Best Cantilever Scaffolding Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Tianjin Jinsheng New Materials Co., Ltd. | Tianjin, CN | Scaffolding, Cantilever Systems | US $20,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging | 2 pieces |

| Suzhou East Engineering Technology Co., Ltd | Suzhou, CN | Scaffoldings (325 listings) | US $800+ | 100% | ≤4h | <15% | Not specified | 1 box / 200 pieces |

| Tianjin Zhiyi Metal Products Co., Ltd. | Tianjin, CN | Scaffolding, Ringlock Systems | US $2,800,000+ | 95% | ≤2h | 40% | Color, material, size, logo, packaging | 50–500 pieces |

| Sichuan Kunzhi Intelligent Technology Co., Ltd. | Sichuan, CN | Ringlock Scaffolding, Steel Pins | US $40,000+ | 100% | ≤1h | 20% | Color, material, size, logo, packaging | 1 ton |

| Xianning City Topway Metal Products Co., Ltd. | Hubei, CN | Scaffoldings (381), Parts | US $1,000+ | 100% | ≤2h | - | Limited to components | 10–100 pieces |

Performance Analysis

Tianjin Zhiyi stands out with the highest reorder rate (40%) and substantial online revenue, suggesting strong customer retention and production maturity despite a slightly lower on-time delivery rate. Tianjin Jinsheng and Sichuan Kunzhi demonstrate rapid responsiveness (≤1h) and full compliance with delivery commitments, ideal for time-sensitive procurement. Suzhou East offers broad product diversity with over 325 scaffold listings, though its higher MOQs (e.g., $999/box) suggest focus on complete system exports. Xianning Topway specializes in individual components like brackets and braces at low MOQs, suitable for replacement parts sourcing. Suppliers with customization tags provide end-to-end adaptability, while those reporting revenue above US $2 million likely operate multi-shift production for bulk contracts.

FAQs

What materials are used in cantilever scaffolding?

Primary structural members are fabricated from Q235 or Q345 carbon steel due to their optimal strength-to-weight ratio and weldability. Components are typically hot-dip galvanized post-welding to ensure long-term corrosion resistance in outdoor environments.

What is the typical MOQ for cantilever scaffolding?

MOQs vary significantly: component suppliers often require 10–100 pieces, while system-level manufacturers set minimums at 50–500 units or 1-ton shipments. Some offer sample orders starting at 2 pieces for initial testing.

Can suppliers customize cantilever scaffolding designs?

Yes, leading suppliers support modifications in platform dimensions, bracket geometry, connection mechanisms, and surface finishes. Custom color coding, branding, and packaging are commonly available for OEM partnerships.

What are common lead times?

Standard orders typically ship within 20–35 days after deposit confirmation. Customized or large-volume batches may require 45–60 days, depending on engineering validation and production scheduling.

How to verify supplier credibility?

Request evidence of ISO 9001 certification, material test certificates (MTCs), and third-party inspection records. Conduct virtual factory audits to assess welding lines, galvanization tanks, and quality control stations. Analyze transaction history, including on-time delivery rates and response consistency.