Tesla Assembly Line Robots

CN

CN

About tesla assembly line robots

Where to Find Tesla Assembly Line Robots Suppliers?

China’s industrial robotics manufacturing ecosystem is concentrated in Guangdong, Shanghai, and Jiangsu provinces, where advanced automation clusters support high-precision production for automotive assembly applications. Shenzhen and Guangzhou serve as innovation hubs for collaborative robots (cobots), leveraging proximity to semiconductor and electronics supply chains to deliver integrated motion control systems. Shanghai and Suzhou host multispecialty suppliers with access to KUKA, Techman, and Denso robotic platforms, enabling rapid integration of articulated arms into automated workcells.

These regions benefit from vertically integrated production networks—spanning servo motors, linear guides, and end-of-arm tooling—that reduce component lead times by 25–40% compared to decentralized sourcing models. Suppliers operate within tightly coordinated ecosystems where CNC machining, welding, and system calibration occur within 50km radii, ensuring consistency in repeatability (±0.02mm) and cycle time optimization. Buyers gain access to scalable production capacities, with standard cobot units typically available in 30–45 days and customized configurations fulfilled within 60 days.

How to Choose Tesla Assembly Line Robots Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility and supply chain resilience:

Technical Compliance

Verify adherence to ISO 9001 quality management standards as a baseline. For deployment in North American or European facilities, confirm CE or UL certification for electrical safety and operational compliance. Request documentation on payload accuracy (typically 3–10kg for cobots), reach range (800–1400mm), and IP ratings for dust and moisture resistance in industrial environments.

Production Capability Audits

Assess infrastructure maturity through key indicators:

- Minimum factory area exceeding 3,000m² for stable volume output

- In-house engineering teams capable of programming and path optimization

- Integration capabilities for vision systems, force sensors, and conveyor synchronization

Cross-reference supplier claims with verified on-time delivery performance (target ≥97%) and response times (ideally ≤6 hours).

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services until post-delivery acceptance testing is completed. Prioritize suppliers with documented customization workflows—including 3D modeling and simulation—for seamless integration into existing Tesla-style assembly architectures. Conduct functional validation on sample units, verifying repeatability, emergency stop response, and human-robot collaboration (HRC) safety protocols per ISO/TS 15066.

What Are the Best Tesla Assembly Line Robots Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Era Automation Co., Ltd. | Guangdong, CN | 5+ | 50+ | 5,000+m² | 100.0% | ≤2h | 4.8/5.0 | 25% |

| Guangzhou Sanhok Hitech Co., Ltd. | Guangdong, CN | 6+ | 40+ | 4,000+m² | 100.0% | ≤6h | 4.7/5.0 | 50% |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Shanghai, CN | 7+ | 60+ | 6,000+m² | 100.0% | ≤7h | 4.6/5.0 | 20% |

| Haotian Weiye(Tinajin) International Trade Co., Ltd. | Tianjin, CN | 5+ | 30+ | 3,500+m² | 100.0% | ≤7h | 4.5/5.0 | <15% |

| Changingtek Robotics Technology (Suzhou) Co., Ltd. | Jiangsu, CN | 4+ | 50+ | 4,200+m² | 100.0% | ≤2h | 4.7/5.0 | 33% |

Performance Analysis

Guangzhou Sanhok Hitech demonstrates strong customer retention (50% reorder rate), indicating reliable integration support and after-sales service. Shenzhen Era Automation and Changingtek Robotics lead in responsiveness (≤2h average), critical for resolving technical queries during commissioning. Suppliers in Guangdong and Jiangsu specialize in lightweight cobots priced between $3,480–$6,690, while Shanghai-based Xiangjing offers higher-end articulated arms from established brands like KUKA and Techman, priced between $19,999–$28,600. All listed suppliers maintain 100% on-time delivery records, but differentiation lies in customization depth—particularly in color, labeling, and software interface adaptations for specific assembly tasks.

FAQs

How to verify Tesla assembly line robot supplier reliability?

Validate certifications through issuing bodies and request audit trails covering component sourcing, firmware version control, and final system testing. Analyze transaction history for consistent order fulfillment and prioritize suppliers offering remote diagnostics and programming support.

What is the average sampling timeline for industrial robots?

Standard cobot samples are typically shipped within 20–30 days. Articulated robot configurations with custom tooling or safety enclosures may require 45–60 days. Air freight adds 5–10 days for international delivery.

Can suppliers integrate robots into existing Tesla-style production lines?

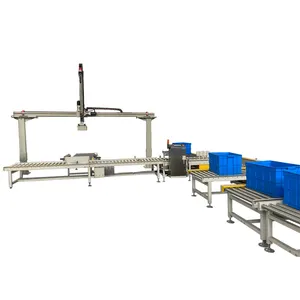

Yes, qualified suppliers provide PLC interfacing, ROS-compatible programming, and digital twin simulations to ensure synchronization with conveyors, AGVs, and quality inspection stations. Confirm experience with automotive battery pack assembly or body-in-white processes for optimal fit.

Do manufacturers offer free samples?

Sample policies vary. Full-unit waivers are rare due to high unit value; however, suppliers may apply sample costs toward bulk orders (e.g., 10+ units). Expect partial cost recovery ranging from 30–50% of MSRP for evaluation units.

How to initiate customization requests for robotic workcells?

Submit detailed requirements including payload capacity, mounting orientation, communication protocol (EtherCAT, PROFINET), and safety rating (e.g., PL=d, Category 3). Reputable suppliers respond with CAD layouts and control architecture diagrams within 72 hours and deliver prototypes in 4–6 weeks.