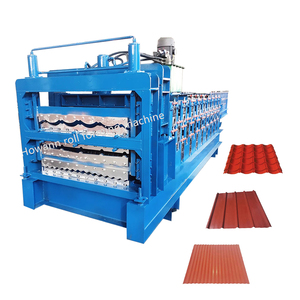

Tile Maker Machine

CN

CN

1/14

1/14

1/19

1/19

CN

CN

1/28

1/28

1/9

1/9

1/23

1/23

CN

CN

1/15

1/15

1/11

1/11

1/19

1/19

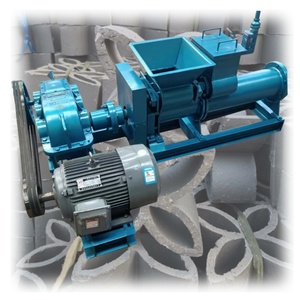

About tile maker machine

Where to Find Tile Maker Machine Suppliers?

China remains the global epicenter for tile maker machine manufacturing, with concentrated industrial hubs in Henan and Jiangsu provinces driving innovation and export capacity. Henan Province accounts for over 50% of China’s tile machinery suppliers, supported by mature ecosystems in Gongyi and Zhengzhou that integrate casting, CNC machining, and final assembly under one supply chain. These clusters benefit from proximity to raw material sources—particularly cement, clay, and steel—reducing component procurement time by up to 30% compared to decentralized regions.

The region's vertically integrated production model enables rapid prototyping and scalable output, with average monthly capacities ranging from 20 to 100 units per facility depending on automation level. Suppliers in Zhengzhou specialize in fully automatic terrazzo and concrete tile machines, while Nanjing-based manufacturers focus on ceramic and glazed tile forming systems. This geographic specialization allows buyers to align supplier selection with specific product requirements, whether high-volume floor tile lines or custom roofing profiles.

How to Choose Tile Maker Machine Suppliers?

Effective supplier evaluation requires a structured approach centered on technical capability, operational reliability, and transaction security.

Technical Compliance & Certification

Verify adherence to ISO 9001 quality management standards as a baseline. For markets in Europe or North America, confirm CE marking compliance to meet safety and electromagnetic compatibility regulations. Request documentation for motor efficiency ratings, hydraulic system pressure tests (typically 16–20 MPa), and structural load validation reports.

Production Capability Assessment

Evaluate key operational metrics:

- Minimum factory area of 3,000m² to support full production cycles

- In-house engineering teams capable of custom mold design and PLC programming

- Proven experience with roll-forming, pressing, and vibration molding technologies

Cross-reference listed machinery specifications with actual production footage where available. Prioritize suppliers with demonstrated reorder rates above 50%, indicating consistent performance and customer satisfaction.

Transaction Safeguards and Quality Control

Utilize secure payment mechanisms such as escrow services until post-delivery inspection is completed. Confirm inclusion of pre-shipment testing protocols, including dry runs and dimensional accuracy checks. Insist on sample validation—especially for customized configurations—to verify tile density, surface finish, and cycle time consistency before mass production.

What Are the Best Tile Maker Machine Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Verified Exporter |

|---|---|---|---|---|---|---|---|---|

| Henan Province Gongyi City East China Metallurgical Coal Mine Machinery Factory | Henan, CN | Terrazo, Cement, Floor Tile Machines | $4,000–7,211 | 100% | ≤6h | - | Not specified | No |

| Zhengzhou Man Machinery Co., Ltd. | Henan, CN | Terrazzo, Marble, Ceramic Tile Machines | $9,999–40,000 | 33% | ≤14h | 50% | Not specified | No |

| Zhengzhou Howann Machinery Inc | Henan, CN | Glazed, Metal Roofing, Roll-Forming Machines | $4,150–13,500 | - | ≤1h | - | Material, size, shaping | No |

| Henan Share M&E Equipment Co.,Ltd | Henan, CN | Concrete, Terrazzo, Clay Tile Machines | $1,860–17,439 | 100% | ≤3h | 19% | Logo | Yes |

| Nanjing Brickmac Engineering Co., Ltd. | Jiangsu, CN | Ceramic, Glazed, Plastic Paving Tile Machines | $1,000–3,250 | 100% | ≤5h | 50% | Color, material, size, logo, packaging, graphic | Yes |

Performance Analysis

Suppliers like Nanjing Brickmac Engineering stand out for extensive customization capabilities and 100% on-time delivery despite lower price positioning, indicating efficient operations. Henan-based manufacturers dominate responsiveness, with three suppliers answering inquiries within 6 hours—critical for time-sensitive procurement cycles. Zhengzhou Man Machinery offers premium equipment targeting commercial-scale terrazzo production but shows a low on-time delivery rate (33%), suggesting potential fulfillment risks. Buyers seeking cost-effective solutions should consider Nanjing Brickmac’s sub-$3,000 models, while large-scale contractors may prioritize Henan Share’s higher-capacity concrete systems with verified export history.

FAQs

How to verify tile maker machine supplier reliability?

Validate certifications through official registries and request third-party audit summaries covering production workflows and quality control checkpoints. Analyze transaction data such as on-time delivery rates and reorder frequency. Conduct video audits of factory floors to assess machinery condition and workflow organization.

What is the typical lead time for tile making machines?

Standard models require 25–40 days for production and preparation. Customized systems, particularly those involving unique molds or control panels, may extend to 50–60 days. Add 10–15 days for international sea freight to most global ports.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers offer OEM branding, including logo integration and color scheme adjustments. Advanced customization—such as tailored forming speeds, mold dimensions, or voltage configurations—is available from suppliers like Nanjing Brickmac and Zhengzhou Howann, provided technical drawings are submitted upfront.

Do suppliers provide installation and training support?

Support varies. Some suppliers include remote guidance via video manuals or live calls. Others offer optional on-site technician deployment at additional cost. Confirm service inclusions prior to order finalization, particularly for complex automated lines.

What are common MOQ and pricing structures?

Most suppliers list a minimum order quantity of 1 set, facilitating trial purchases. Pricing correlates strongly with automation level: semi-automatic models start below $2,000, while fully automatic lines exceed $20,000. Bulk orders (5+ units) typically qualify for 5–10% discounts and reduced shipping costs per unit.