Types Of Precision Machining

Top sponsor listing

Top sponsor listing

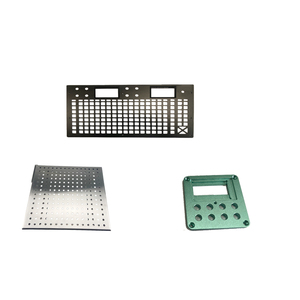

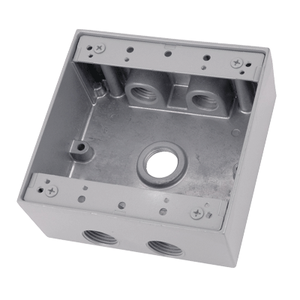

About types of precision machining

Where to Find Precision Machining Suppliers?

China remains a global hub for precision machining services, with key manufacturing clusters concentrated in Guangdong and Fujian provinces. Shenzhen and Dongguan in Guangdong host advanced CNC machining ecosystems supported by mature supply chains for raw materials, tooling, and metrology equipment. Xiamen in Fujian has emerged as a specialized center for high-precision aluminum and brass components, leveraging regional expertise in tight-tolerance milling and turning operations.

These industrial zones offer integrated production networks where suppliers maintain in-house capabilities across CNC machining, sheet metal fabrication, die casting, and surface treatments such as anodization and plating. This vertical integration enables rapid prototyping (typically 5–7 days) and low-volume production scalability. Buyers benefit from localized sourcing of aerospace-grade aluminum, stainless steel, brass, and engineering plastics, reducing material lead times by 20–30% compared to offshore alternatives. Average production costs are 15–25% lower due to optimized labor efficiency and energy-intensive process clustering.

How to Choose Precision Machining Suppliers?

Procurement decisions should be guided by systematic evaluation criteria to ensure technical compliance and operational reliability:

Technical Capabilities & Certifications

Verify ISO 9001 certification as a baseline for quality management systems. For regulated industries (medical, automotive, aerospace), confirm adherence to AS9100, IATF 16949, or ISO 13485 standards. Request documentation on coordinate measuring machine (CMM) inspection reports, first-article inspections (FAI), and process capability (Cp/Cpk) data for critical dimensions.

Production Infrastructure Assessment

Evaluate supplier capacity based on the following benchmarks:

- Minimum of 50+ CNC machines (3-axis, 4-axis, and 5-axis) for complex geometries

- In-house secondary operations: deburring, heat treatment, welding, and assembly

- Dedicated metrology lab with CMM, optical comparators, and surface roughness testers

Cross-reference equipment lists with online revenue metrics and order fulfillment rates (target ≥96%) to validate scalability and consistency.

Customization & Quality Control Protocols

Confirm support for full design-to-production workflows, including DFM analysis, CAD/CAM compatibility (SolidWorks, STEP, IGES), and custom packaging/labeling. Prioritize suppliers offering material traceability, batch tracking, and PPAP documentation. On-time delivery performance above 96% and response times under 3 hours indicate strong operational discipline.

What Are the Best Precision Machining Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Sheet Metal Fabrication (574), Machining Services (70) | 96% | ≤3h | 48% | US $1,700,000+ | Anodization, stamping, die casting, assembly, graphic labeling |

| Shenzhen Tengyuan Precision Machinery Co., Ltd. | Machining Services (26) | 94% | ≤2h | 45% | US $7,000+ | Brass/aluminum CNC parts, casting, customization per drawings |

| Ald Precision Manufacturing Co., Ltd. | Casting Services (223), Machining Services (107) | 100% | ≤1h | - | US $1,000+ | Full CNC machining, industrial tools, equipment components |

| Dongguan Best Precision Hardware Products Co., Ltd. | Machining Services (3947) | 100% | ≤2h | 31% | US $110,000+ | Stainless steel, aluminum, custom metal machining |

| Xiamen XiangJI Precision Machinery Technology Co,Ltd | Machining Services (370) | 96% | ≤2h | 75% | US $190,000+ | Aluminum, brass, stainless steel CNC milling, small-part production |

Performance Analysis

Dongguan Best Precision leads in service volume with over 3,900 machining listings and perfect on-time delivery, indicating robust production scheduling. Xiamen XiangJI stands out with a 75% reorder rate—among the highest in the sector—suggesting consistent quality and customer satisfaction for small-batch, high-mix orders. Ald Precision achieves 100% on-time performance with sub-one-hour response times, ideal for urgent prototyping needs despite lower public revenue visibility. Shenzhen Runze offers the broadest secondary processing options, including die casting and rubber coating, suitable for fully assembled subsystems. While Shenzhen Tengyuan has fewer listings, its focus on brass components aligns with niche applications in fluid systems and electrical connectors.

FAQs

What materials are commonly used in precision machining?

Standard materials include 6061 and 7075 aluminum, 303 and 316 stainless steel, C360 brass, and engineering plastics like PEEK and Delrin. Material selection depends on mechanical requirements, corrosion resistance, and machinability index.

What is the typical MOQ and pricing range?

MOQ varies from 1 piece for prototypes to 50–100 units for production runs. Unit prices range from $0.01–$12 depending on complexity, material, and finishing. High-volume orders achieve up to 40% cost reduction through process optimization.

How long does it take to receive machined parts?

Standard lead time is 7–14 days for CNC-machined prototypes and 15–25 days for bulk orders including surface treatments. Express services can reduce turnaround to 3–5 days at a premium.

Can suppliers handle full project lifecycle support?

Yes, leading providers offer end-to-end services: design review, DFM feedback, rapid prototyping, production, QC reporting, and kitted packaging. Some also provide FAI reports, SPC charts, and reusable fixtures for repeat orders.

Are samples available before mass production?

Most suppliers offer sample production at standard pricing, often waiving fees if followed by a production order. Sample costs typically cover setup, tooling, and labor, ranging from $50–$300 depending on part complexity.