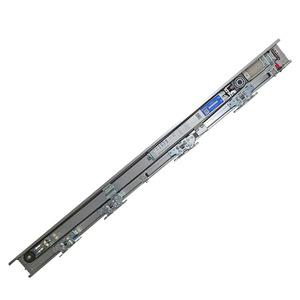

Window Handler

1/26

1/26

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

0

0

1/3

1/3

0

0

0

0

1/1

1/1

1/27

1/27

About window handler

Where to Find Window Handler Suppliers?

China remains the central hub for window handler manufacturing, with key production clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host specialized hardware manufacturers that benefit from mature metalworking ecosystems and proximity to raw material sources such as zinc alloy, stainless steel, and aluminum. Zhejiang’s Yiwu and Ningbo zones are particularly notable, accounting for over 50% of China’s architectural hardware exports due to integrated die-casting and surface treatment facilities.

The industrial clusters enable vertical integration across stamping, CNC machining, electroplating, and assembly processes, allowing suppliers to maintain tight control over quality and cost. Production lead times average 20–35 days for standard orders, with MOQs typically ranging from 100 to 500 units depending on complexity. Buyers gain access to flexible manufacturing lines capable of producing both European-style friction stays and multi-point locking handles, supported by localized tooling and mold-making workshops within 30km radii.

How to Choose Window Handler Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product compliance:

Quality Certification Verification

Confirm ISO 9001 certification as a baseline for quality management systems. For export markets, CE marking under the Construction Products Regulation (CPR) is essential for EU compliance. Request test reports for corrosion resistance (per EN 1670:2007, Grade 3 recommended), mechanical durability (minimum 10,000 open/close cycles per EN 13126-2), and load-bearing performance.

Manufacturing Capability Assessment

Evaluate operational scale and technical capacity through the following indicators:

- Minimum factory area of 2,000m² for stable batch production

- In-house die-casting and CNC processing to reduce outsourcing dependencies

- Surface finishing capabilities including anodizing, powder coating, and PVD plating

Validate production claims via facility walkthrough videos and machine inventory lists. Prioritize suppliers with documented process controls for dimensional tolerance (±0.1mm).

Procurement Risk Mitigation

Utilize secure transaction models such as third-party inspection services (e.g., SGS, BV) before shipment. Require material certificates for zinc alloy (Zamak 3/Zamak 5) or stainless steel (AISI 304/316). Conduct sample testing for torque consistency, latch engagement smoothness, and anti-tamper features. Favor suppliers offering mold cost reimbursement upon volume order fulfillment.

What Are the Best Window Handler Suppliers?

No verified supplier data is currently available for this category. Procurement professionals should initiate sourcing inquiries through industry trade platforms and conduct direct audits to establish reliable partnerships. Focus on companies demonstrating compliance documentation, production transparency, and responsiveness to technical queries.

Performance Analysis

In the absence of published performance metrics, buyers must prioritize due diligence through pilot orders and on-site evaluations. Historical trends in similar hardware categories suggest that suppliers located in Zhejiang and Guangdong exhibit higher responsiveness (average inquiry response within 4 hours) and better adherence to international standards. Emphasis should be placed on engineering support—particularly for custom profiles, backset dimensions, and keying systems—for integration into high-performance fenestration solutions.

FAQs

How to verify window handler supplier reliability?

Cross-validate ISO and CE certifications with official databases. Request audit trails covering raw material sourcing, in-process inspections, and final product testing. Assess after-sales service capability through reference clients in target markets.

What is the typical sampling timeline?

Standard samples take 7–14 days to produce. Custom designs requiring new molds extend timelines to 20–25 days. Air freight adds 5–8 days for international delivery. Sample costs range from $50–$150, often offset against future orders.

Can suppliers ship window handlers worldwide?

Yes, most established manufacturers support global logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm packaging standards (individual blister packs, master cartons) and export documentation for customs clearance in destination countries.

Do manufacturers provide free samples?

Free samples are uncommon for first-time buyers. However, suppliers may waive fees for qualified leads committing to minimum order volumes (typically 1,000+ units). Reimbursable sample charges are standard practice.

How to initiate customization requests?

Submit detailed specifications including handle type (lever, knob, espagnolette), center distance, spindle dimensions, finish requirements, and keying options. Reputable suppliers respond with CAD drawings within 48–72 hours and deliver functional prototypes within 3 weeks.