Launching a watch brand in today’s competitive market requires more than just design flair—it demands a strategic partnership with a capable OEM (Original Equipment Manufacturer). The right manufacturer shapes product quality, production timelines, and long-term brand reputation. Yet many entrepreneurs overlook critical vetting steps, leading to delays, inconsistent craftsmanship, or even intellectual property risks. This guide walks through the essential factors to evaluate when selecting an OEM partner, from technical capability to communication transparency.

Understanding What Makes an OEM Reliable

A reliable OEM doesn’t just produce watches—it acts as an extension of your brand. True reliability combines consistent quality control, ethical labor practices, scalability, and responsiveness. While some manufacturers offer low prices, they may lack precision engineering or fail to protect your designs. Others may boast advanced machinery but struggle with communication across time zones.

The foundation of a trustworthy OEM lies in three pillars: proven track record, technical expertise, and alignment with your brand values. For example, if your brand emphasizes sustainability, a manufacturer using recycled materials and energy-efficient processes becomes non-negotiable. Likewise, if you’re targeting luxury consumers, certifications like ISO 9001 or partnerships with Swiss movement suppliers signal higher standards.

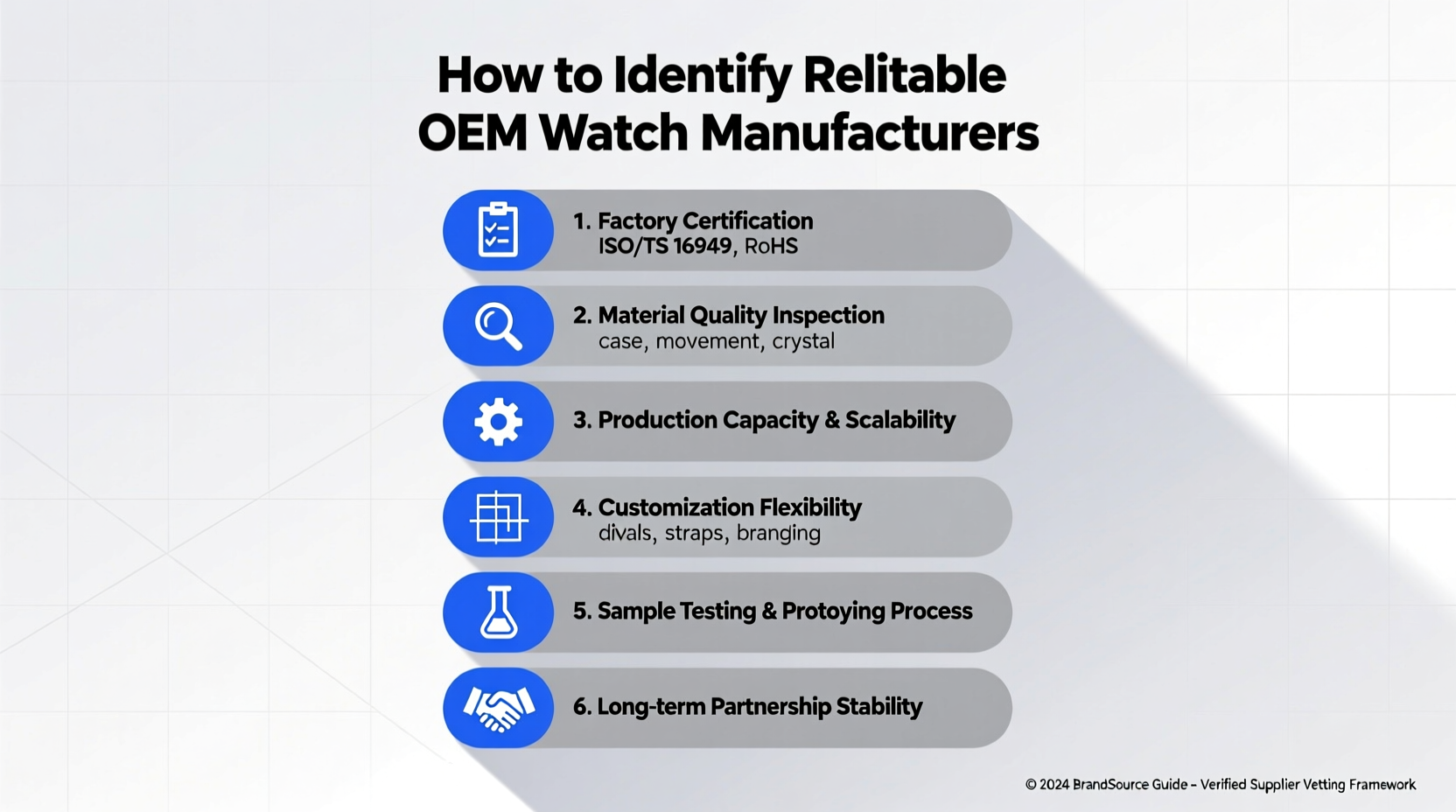

Key Evaluation Criteria for Watch OEMs

Selecting a manufacturer isn’t about finding the cheapest option; it’s about matching capabilities to your brand’s vision. Consider these five core areas:

- Production Capacity and Minimum Order Quantities (MOQs): Startups often need flexible MOQs. A manufacturer requiring 10,000 units may be unsuitable for a new brand testing the market. Look for partners offering 500–2,000 unit minimums with room to scale.

- Movement Sourcing: Whether quartz, mechanical, or smart modules, verify where the OEM sources movements. Reputable brands prefer Miyota, Ronda, or Sellita over unbranded clones.

- Materials Quality: Stainless steel grade, sapphire vs. mineral crystal, and strap materials directly impact durability and perceived value. Ask for material certifications.

- Quality Assurance Processes: In-line inspections, water resistance testing, and final QC audits should be documented. Request copies of their QA reports.

- Intellectual Property Protection: Ensure contracts include clauses on design ownership, non-disclosure, and restrictions on reselling your designs.

Do’s and Don’ts When Vetting Manufacturers

| Do | Don't |

|---|---|

| Visit the factory in person or via video tour | Rely solely on third-party agents without verifying credentials |

| Ask for client references in your niche | Assume high-volume output guarantees quality |

| Test communication responsiveness over 2–3 weeks | Sign contracts without legal review |

| Negotiate payment terms (e.g., 30% deposit, 70% on delivery) | Pay 100% upfront |

Step-by-Step Guide to Selecting Your OEM Partner

Finding the right manufacturer is a process, not a one-off decision. Follow this timeline to reduce risk and build confidence:

- Week 1–2: Define Your Requirements

Create a clear spec sheet including case dimensions, movement type, water resistance rating, packaging, and target price per unit. - Week 3–4: Shortlist 5–7 Manufacturers

Use platforms like Alibaba, Global Sources, or industry trade shows. Prioritize those with verified facilities and at least three years in business. - Week 5: Initial Outreach and Screening

Contact each with your specs. Gauge response time, clarity, and willingness to ask clarifying questions—these reflect engagement level. - Week 6–7: Request Samples and References

Order prototypes from top 3 candidates. Simultaneously contact listed clients to ask about reliability and problem resolution. - Week 8: Factory Assessment

If possible, conduct a virtual audit via live video showing production lines, QC stations, and raw material storage. - Week 9: Final Negotiation and Contract

Finalize pricing, lead times, and IP terms. Use an international trade lawyer to draft or review the agreement. - Week 10: Pilot Run

Start with a small batch (e.g., 500 units). Inspect every detail upon arrival before scaling up.

“Many brands fail because they treat manufacturing as a transaction. The strongest partnerships are built on mutual respect, transparency, and shared goals.” — Daniel Reyes, Supply Chain Consultant, Timepiece Advisors Group

Real-World Example: How Nova Chrono Avoided a Costly Mistake

In 2022, Nova Chrono, a U.S.-based startup, was preparing to launch its first automatic watch line. After receiving glowing quotes from a Chinese OEM promising low costs and fast turnaround, the team nearly signed a six-figure contract. However, during due diligence, they requested a sample. The prototype arrived with misaligned hands, inconsistent brushing on the case, and a movement that lost 20 minutes per day.

Further investigation revealed the factory primarily produced fashion quartz watches and had outsourced the automatic movement assembly to a subcontractor. Nova Chrono pivoted to a smaller Shenzhen-based OEM specializing in mechanical timepieces. Though the unit cost was 18% higher, the quality, communication, and post-launch support proved invaluable. Their debut collection sold out in eight weeks, with customers praising accuracy and finish.

Essential Checklist Before Signing with an OEM

- ✅ Verified business license and factory address

- ✅ At least two client references in the watch industry

- ✅ Clear documentation of materials and movement sources

- ✅ Sample batch meets all design and functional specs

- ✅ Contract includes IP protection and dispute resolution clause

- ✅ Payment terms allow partial release upon delivery

- ✅ Openness to third-party inspection (e.g., SGS or Bureau Veritas)

- ✅ Realistic production timeline with buffer for delays

Frequently Asked Questions

How do I know if an OEM is hiding subcontracting?

Ask directly and request a full breakdown of the production process. Reliable OEMs will disclose subcontracted stages like plating or engraving. Red flags include vague answers or refusal to show certain factory areas during tours.

Can I work with an OEM that doesn’t speak fluent English?

Yes, but ensure they have a dedicated project manager fluent in your language. Miscommunication in specifications—such as crown position or lug width—can result in unusable batches. Use detailed CAD drawings and written summaries to minimize errors.

What’s the average lead time for a custom watch order?

Typically 60 to 90 days from approval to shipment, depending on complexity. Mechanical watches with custom movements may take 120+ days. Factor in additional time for shipping, customs, and final quality checks before launch.

Building a Partnership That Lasts

Choosing an OEM is one of the most consequential decisions for a watch brand. It affects everything from customer satisfaction to your ability to iterate designs and respond to market trends. Beyond technical competence, look for a partner willing to grow with you—someone who offers feedback, suggests improvements, and treats your product as their own.

Transparency, consistency, and mutual accountability form the backbone of lasting success. As your brand evolves, so should your manufacturing relationship. Regular reviews, open communication channels, and shared investment in quality will set the foundation for long-term excellence.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?