3d Printing Is Used To Produce Complex

Top sponsor listing

Top sponsor listing

1/9

1/9

1/25

1/25

1/23

1/23

1/12

1/12

1/22

1/22

1/31

1/31

1/7

1/7

1/18

1/18

About 3d printing is used to produce complex

Where to Find Suppliers for 3D Printing of Complex Components?

China remains a dominant hub for advanced 3D printing services, particularly in manufacturing complex geometries and functional prototypes. Key industrial clusters are concentrated in Shenzhen, Shanghai, and Guangzhou—cities known for their precision engineering ecosystems and rapid prototyping infrastructure. These regions host specialized additive manufacturing firms equipped with multi-technology platforms including SLS, MJF, SLA, FDM, and metal-based processes such as DMLS and EBM.

The concentration of technical expertise and vertically integrated supply chains enables competitive advantages in both cost and turnaround time. Suppliers in these zones typically operate within mature industrial networks that include material suppliers, post-processing specialists, and quality control labs—all within close proximity. This integration supports lead times averaging 7–15 days for custom orders, with scalability for batch production up to several thousand units monthly. Buyers benefit from localized access to engineering talent and digital manufacturing workflows optimized for design iteration and low-volume customization.

How to Choose 3D Printing Suppliers for Complex Parts?

Selecting the right supplier requires rigorous evaluation across technical capability, operational reliability, and customization flexibility:

Technical & Process Capabilities

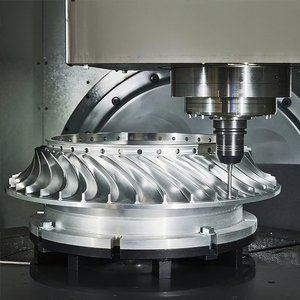

Verify support for high-resolution additive technologies suitable for intricate designs: SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) are preferred for durable nylon components; SLA/DLP for fine-detail resin models; and metal AM (e.g., DMLS, SLM) for complex metallic structures. Confirm availability of secondary operations such as CNC finishing, heat treatment, electroplating, polishing, and vacuum casting to achieve required surface finishes and mechanical properties.

Quality Assurance and Compliance

Prioritize suppliers adhering to recognized quality management systems such as ISO 9001. While not always explicitly stated, evidence of consistent on-time delivery (>98%), documented inspection protocols, and process validation indicates robust internal controls. For regulated industries (medical, aerospace), request material traceability reports and compliance with standards like RoHS or REACH.

Customization and Design Support

Evaluate the breadth of customization options offered, including:

- Material selection: Nylon (PA12), TPU, ABS, PC, PLA, resins, titanium alloy, stainless steel (316L), silver, full-color composites

- Surface treatments: Sandblasting, spray painting, water-based coating, plating, coloring, labeling, silk screening

- Design modifications: Reverse modeling, hollowing, dimension adjustment, gear integration, assembly simulation

- Digital deliverables: 3D renderings, mold flow analysis, video confirmation of finished parts

Cross-reference customization claims with actual product listings to ensure technical feasibility and pricing transparency.

Transaction Reliability Indicators

Analyze performance metrics where available:

- On-time delivery rate ≥98%

- Average response time ≤4 hours

- Reorder rate >30% as an indicator of customer satisfaction

- Minimum online transaction volume (e.g., US $50,000+) suggesting commercial scale

Suppliers with verified order histories and detailed service descriptions demonstrate greater accountability. Request sample parts to validate dimensional accuracy, surface finish, and material consistency before scaling procurement.

What Are the Leading 3D Printing Suppliers for Complex Geometries?

| Company Name | Main Technologies | Materials Supported | Min. Order Quantity | Pricing Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Strongd Model Technology Co., Ltd. | Machining, Moulding, Casting, Fabrication | Aluminum, Plastics, Custom Alloys | 1 piece | $200+ | 98% | ≤2h | 43% | $50,000+ |

| Yongkang Qucheng Technology Co., Ltd. | SLS, Metal 3D Printing, Functional Prototyping | Nylon, Titanium Alloy, 316L, Resin, TPU, Full-Color | 1 piece | $1–10 | 99% | ≤2h | 35% | $230,000+ |

| Shanghai Ruihaisi Intelligent Machinery Co., Ltd. | FDM, MJF, Resin Printing | Nylon, PLA, ABS, Resin | 1 piece | $0.15–0.56 / $3.50 | 100% | ≤16h | <15% | $1,000+ |

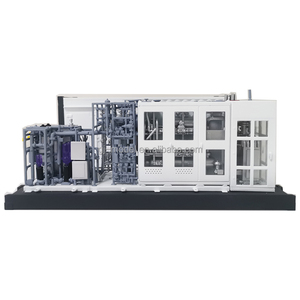

| FastForm 3D Technology Co., Ltd. | Industrial Metal 3D Printers | Machine Manufacturing (Not Service) | 1 unit | $999–$55,000 | Not Available | ≤10h | <15% | $160,000+ |

| Guangzhou Gaojie Model Design And Manufacturing Co., Ltd. | SLA, CNC, Vacuum Casting | Resin, PC, ABS, PETG, Brass, Aluminum | 1 piece | $0.30–2.59 | 96% | ≤4h | 59% | $80,000+ |

Performance Analysis

Among service providers, Yongkang Qucheng stands out for its extensive material portfolio and strong delivery performance (99%), supporting applications from functional nylon gears to metal structural components. Despite higher per-unit pricing, its broad customization scope—including plating, engraving, and environmental resistance treatments—makes it suitable for high-specification prototypes. Shenzhen Strongd offers premium services focused on integrated fabrication, though at significantly higher entry costs ($200 minimum).

For cost-sensitive buyers, Shanghai Ruihaisi provides some of the lowest per-part pricing using FDM and MJF technologies, but its lower reorder rate (<15%) and slower response time suggest potential gaps in post-sale engagement. Guangzhou Gaojie demonstrates the highest reorder rate (59%), indicating strong client retention, supported by versatile finishing capabilities and responsive communication.

FastForm 3D diverges from the service model by supplying industrial-grade metal 3D printers rather than printed parts, targeting buyers seeking in-house production capacity. Its equipment range includes machines priced up to $55,000, suitable for enterprises investing in internal additive manufacturing infrastructure.

FAQs

What materials are commonly used in complex 3D printed parts?

Common materials include nylon (PA12) for strength and flexibility, photopolymer resins for high detail, TPU for elasticity, and metals like 316L stainless steel and titanium alloys for industrial applications. Material selection depends on mechanical requirements, environmental exposure, and post-processing needs.

What is the typical MOQ and lead time?

Most suppliers offer a minimum order quantity of 1 piece, ideal for prototyping and small batches. Lead times generally range from 5 to 12 days depending on complexity, technology used, and required finishing. Expedited services may reduce this to 3–5 days at a premium.

Can I customize size, color, and finish?

Yes, nearly all listed suppliers support size modification, color dyeing, spray painting, electroplating, sandblasting, and graphic application. Some offer Pantone-matched finishes, glossy/matte coatings, and non-absorbent surface treatments for specialized use cases.

Do suppliers provide design validation?

Reputable manufacturers offer pre-production services such as 3D modeling, mold rendering, reverse engineering, and dimensional verification. Video confirmation of completed parts is increasingly common to ensure compliance without physical inspection.

Are samples available before bulk ordering?

Yes, most suppliers produce single-piece samples for validation. Sample costs vary by part complexity and material but typically reflect full production pricing. Some may credit sample fees toward larger orders.