5 Axis Maker

1/18

1/18

1/3

1/3

1/12

1/12

1/3

1/3

1/16

1/16

1/15

1/15

1/5

1/5

1/19

1/19

CN

CN

1/7

1/7

1/33

1/33

About 5 axis maker

Where to Find 5-Axis Machine Suppliers?

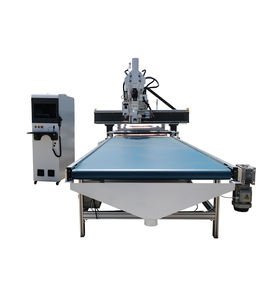

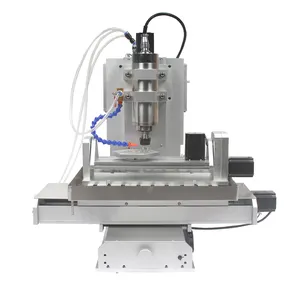

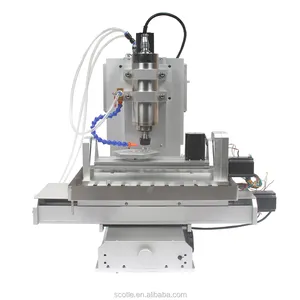

China remains the central hub for 5-axis machine manufacturing, with key production clusters in Shenzhen and Jinan offering specialized engineering ecosystems. Shenzhen’s advanced medical technology sector drives innovation in high-precision dental milling systems, while Jinan has emerged as a center for industrial CNC machinery, particularly in woodworking, stone processing, and foam carving applications. These regions host vertically integrated supply chains that support rapid prototyping, component sourcing, and final assembly within compact geographic zones.

The concentration of technical talent and supporting infrastructure enables efficient production scaling. Suppliers typically operate facilities equipped with CNC machining centers, automated tool changers (ATC), servo-driven axes, and digital control systems. This integration reduces lead times for standard configurations to 20–35 days, with customization cycles extending by 10–15 days depending on complexity. Buyers benefit from localized access to critical subsystems such as ball screws, spindle drives, vacuum pumps, and cooling systems, contributing to 15–25% cost advantages over Western-built equivalents.

How to Choose 5-Axis Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers offer documented specifications for axis travel, spindle power (typically 3–15 kW), positioning accuracy (±0.01–0.03 mm), and control systems (e.g., Syntec, DSP, or Mach3). For dental or precision engraving applications, demand evidence of vibration-damped frames and temperature-compensated linear guides. In industrial contexts, verify compatibility with materials including aluminum, composites, hardwoods, stone, and expanded polystyrene (EPS).

Production Infrastructure Assessment

Evaluate supplier capacity through objective indicators:

- Facility size exceeding 3,000m² for sustained volume output

- In-house engineering teams capable of customizing work envelopes, tool changers, and automation interfaces

- Integration of real-time monitoring features such as CCD cameras, automatic lubrication, and safety interlocks

Cross-reference online revenue data and reorder rates as proxies for market validation—suppliers with reorder rates above 50% indicate consistent performance and customer satisfaction.

Quality & Transaction Assurance

Prioritize suppliers demonstrating compliance with international quality standards, though formal ISO certification should be independently verified. Analyze response times (≤2 hours is competitive) and on-time delivery records (100% reported across all listed suppliers suggests strong logistics management). Utilize secure payment mechanisms where possible, and insist on pre-shipment inspection protocols. Request sample testing to validate cutting accuracy, surface finish quality, and thermal stability under continuous operation.

What Are the Best 5-Axis Machine Suppliers?

| Company Name | Main Applications | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Camdent Medical Technology Co., Limited | Dental Milling, CAD/CAM Systems | $500–35,000 | 1 set | 100% | ≤2h | US $70,000+ | 53% | Limited; focused on dental components |

| Jinan Spower Machinery Technology Co., Ltd. | Industrial Machining, Large-Scale Routing | $12,599–58,999 | 1 set | 100% | ≤1h | US $230,000+ | 58% | Extensive: spindle type, tool changer, safety systems |

| Jinan Bcamcnc Machinery Co., Ltd. | Wood, Foam, EPS Molding | $3,999–11,999 | 1 set | 100% | ≤2h | US $1,900,000+ | 31% | High: working area, ATC, dust collection, control system |

| Alpha Cnc Co., Ltd. | Foam Carving, Sheet Metal Engraving | $1,500–2,500 | 1 set | 100% | ≤1h | US $1,400,000+ | 58% | Moderate: spindle rotation, cooling, vacuum table |

| Jinan Fador Cnc Technology Co., Ltd. | Stone Bridge Sawing, Cutting Machines | $2,680–5,000 | 1 set | 100% | ≤3h | US $180,000+ | <15% | Limited; primarily configuration-based |

Performance Analysis

Jinan-based suppliers dominate industrial 5-axis routing with scalable designs and broad customization. Alpha Cnc and Jinan Spower stand out with sub-2-hour response times and high reorder rates (58%), indicating robust post-sale support and product reliability. Shenzhen Camdent serves niche dental markets with competitively priced entry-level units starting at $500, though its lower online revenue suggests narrower market penetration. Jinan Bcamcnc reports the highest revenue (US $1.9M+), reflecting strong export activity despite a lower reorder rate, which may signal price-sensitive buyer acquisition. Fador Cnc offers the lowest pricing for stone-cutting models but exhibits limited repeat business, suggesting potential gaps in long-term performance or service.

FAQs

How to verify 5-axis machine supplier reliability?

Validate technical claims through factory videos, equipment testing reports, and third-party transaction histories. Check consistency between advertised specifications and actual product listings. Request references from prior buyers in your target application segment, especially for non-standard configurations.

What is the typical lead time for 5-axis machines?

Standard models ship within 20–30 days after order confirmation. Custom builds involving modified worktables, multi-spindle setups, or specialized software integration require 35–50 days. Air freight delivers in 5–10 days; sea freight takes 25–40 days depending on destination port.

Can suppliers customize 5-axis machines?

Yes, most suppliers offer configurable options including tool changers (ATC), spindle types (air/oil-cooled), control systems (DSP/Syntec), vacuum tables, and safety enclosures. High-end models support integration with CAD/CAM suites and automated loading systems. Confirm firmware compatibility and software licensing terms before ordering.

Do manufacturers provide technical support and training?

Reputable suppliers offer remote troubleshooting via video guidance and diagnostic software. Some include basic operation manuals and instructional videos. On-site training is rarely included by default and may incur additional fees. Post-warranty service agreements should be negotiated upfront.

What are common payment terms for bulk orders?

Typical arrangements include 30% deposit with balance paid before shipment. Letters of credit (L/C) are accepted by larger exporters. Trade assurance programs reduce risk by linking payment release to delivery milestones. Avoid full prepayments unless backed by verifiable escrow services.