Aac Block Machine Price In India

Top sponsor listing

Top sponsor listing

1/49

1/49

1/19

1/19

1/19

1/19

CN

CN

1/12

1/12

CN

CN

1/18

1/18

CN

CN

1/18

1/18

1/24

1/24

1/30

1/30

About aac block machine price in india

Where to Find AAC Block Machine Suppliers in India?

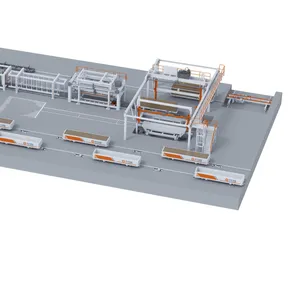

China remains the primary global hub for AAC (Autoclaved Aerated Concrete) block machine manufacturing, with concentrated industrial clusters in Shandong and Henan provinces driving supply chain efficiency. Shandong, particularly regions around Jinan and Jining, hosts specialized construction machinery manufacturers equipped with integrated steel processing and automation systems, enabling 15–25% cost advantages over localized Indian production. Henan’s Zhengzhou-centered cluster leverages dense networks of component suppliers and logistics infrastructure, facilitating rapid assembly and export readiness.

These manufacturing ecosystems support vertically integrated operations—from mold fabrication to full production line assembly—allowing suppliers to deliver complete turnkey plants within 45–60 days. Buyers benefit from proximity to raw material sources (e.g., hydraulic components, control panels, and steel billets), reducing procurement lead times by up to 30%. The region's mature industrial base ensures access to skilled technicians, third-party engineering validation, and scalable production capacity suitable for both small-scale startups and large industrial deployments in India.

How to Choose AAC Block Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

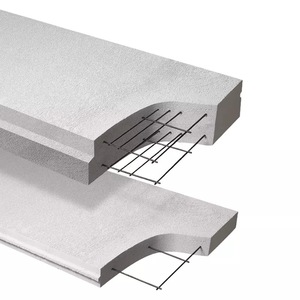

Verify ISO 9001 certification as a baseline for quality management systems. For compliance with Indian building standards (IS: 2185-3), ensure machine design supports standard block formats (e.g., 600×200×100 mm) and density ranges (450–800 kg/m³). CE marking is critical for equipment safety and regulatory acceptance in formal construction sectors. Request documentation on motor power ratings (typically 30–75 kW), hydraulic pressure tolerances (16–25 MPa), and vibration system specifications to confirm process reliability.

Production Capability Assessment

Evaluate supplier infrastructure based on:

- Minimum factory area exceeding 3,000m² for full-line production

- In-house capabilities in mold design, PLC-based control systems, and automated stacking/palletizing

- Monthly output capacity of ≥5 production lines or equivalent modular units

Cross-reference delivery performance (target ≥95% on-time rate) with online revenue indicators and reorder rates to assess operational stability.

Customization & Engineering Support

Confirm availability of customization for brick size (standard vs. custom molds), automation level (semi-automatic to fully automatic), and integration with silos, mixers, and autoclaves. Reputable suppliers provide CAD drawings, control panel layouts, and material flow diagrams upon request. Prioritize vendors offering site-specific plant layout planning and commissioning support for Indian market conditions.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as letter of credit (LC) or escrow services tied to milestone inspections. Validate supplier claims through video audits of production progress and pre-shipment testing. Conduct sample trials to benchmark mixing homogeneity, cutting precision, and curing cycle consistency before final deployment.

What Are the Leading AAC Block Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Key Features |

|---|---|---|---|---|---|---|---|

| Henan Zhongke Engineering & Technology Co., Ltd. | Henan, CN | Brick Making Machinery, Cement Plants, AAC Lines | 100% | 33% | ≤6h | US $1.2M+ | Fully automatic lines; German technology integration; 200,000+ unit annual output capacity |

| Shandong Kaidong Construction Machinery Co., Ltd. | Shandong, CN | Brick, Tile, Cement Machinery | 100% | 16% | ≤2h | US $320K+ | High customization; hydraulic forming systems; modular design for easy shipping to India |

| Shandong Weida Construction Machinery Co., Ltd. | Shandong, CN | AAC Block Machines, ICF Systems, Green Building Solutions | 80% | 25% | ≤3h | US $270K+ | Turnkey projects; wide price range ($18K–$600K); scalable small-to-large plants |

| Shanghai Minggong Heavy Equipment Co., Ltd. | Shanghai, CN | Brick, Crusher, Cement Machinery | 100% | - | ≤6h | - | Compact systems; entry-level pricing ($10.5K/set); suitable for pilot plants |

Performance Analysis

Henan Zhongke stands out with the highest verified online revenue and a strong reorder rate, indicating consistent customer satisfaction and technical reliability. Shandong Kaidong leads in responsiveness (≤2h) and delivery consistency, making it ideal for time-sensitive procurement cycles. Shandong Weida offers the broadest product range and flexible investment tiers, catering to Indian buyers seeking incremental scalability. Shanghai Minggong provides cost-effective entry-level solutions but lacks reorder data, suggesting limited long-term engagement metrics. Buyers should prioritize suppliers with transparent pricing structures, documented after-sales service, and proven experience in tropical climate installations relevant to India.

FAQs

What is the typical price range for AAC block machines in India?

Prices vary significantly by automation level and capacity. Entry-level semi-automatic systems start at $10,500/set, while fully automated turnkey plants range from $200,000 to $600,000. Modular configurations allow phased investment aligned with production growth.

What are common MOQ and lead times?

Standard minimum order quantity is 1 set or plant. Lead times average 45–60 days for full production lines, depending on customization complexity. Stock models may ship within 30 days.

Can suppliers customize machines for Indian market requirements?

Yes, leading suppliers offer adaptations for local voltage (415V/3-phase), ambient temperature resilience, and compatibility with regional raw materials (fly ash, sand, cement ratios). Custom mold sizes and stacker configurations are routinely available.

Do suppliers provide installation and training support?

Most manufacturers include basic commissioning guidance. Premium vendors offer on-site technician deployment, operator training, and process optimization services—verify inclusion terms during negotiation.

How to evaluate machine durability and maintenance needs?

Assess wear-prone components: mold lifespan (≥5 years), hydraulic seal quality, and corrosion-resistant coatings. Request preventive maintenance schedules and spare parts catalogs. Benchmark against industry standards like DIN 4223 or IS: 2185-3 for structural performance.