Advanced Manufacturing And Robotics

Top sponsor listing

Top sponsor listing

CN

CN

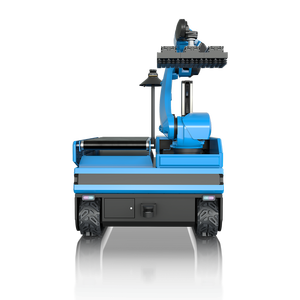

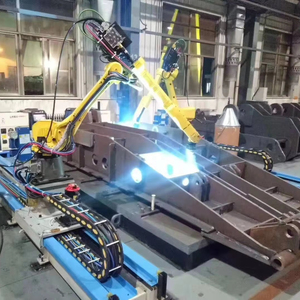

About advanced manufacturing and robotics

Where to Find Advanced Manufacturing and Robotics Suppliers?

China remains a global hub for advanced manufacturing and robotics production, with concentrated supplier clusters in Shanghai, Suzhou, Guangzhou, and Shenzhen. These regions host vertically integrated ecosystems combining R&D centers, precision engineering workshops, and automation component suppliers within close geographic proximity. The Yangtze River Delta—particularly Shanghai and Suzhou—supports high-density collaboration between industrial robot developers and smart factory solution providers, enabling rapid prototyping and system integration.

Manufacturers in these zones benefit from mature supply chains for servo motors, controllers, sensors, and structural components, reducing lead times by 20–35% compared to non-specialized regions. Facilities typically operate under ISO 9001-aligned quality management systems, with many offering CE-certified designs compliant with European machinery directives. Buyers gain access to scalable production capacities, with leading suppliers maintaining monthly output capabilities exceeding 300 units across collaborative, articulated, and mobile robotic platforms.

How to Choose Advanced Manufacturing and Robotics Suppliers?

Effective supplier selection requires structured evaluation of technical, operational, and transactional performance indicators:

Technical Capability Verification

Confirm alignment with application-specific requirements: payload capacity, degrees of freedom (DoF), repeatability tolerance (±0.02–0.1mm typical), and control interface compatibility (e.g., ROS, PLC integration). For collaborative robots (cobots), validate built-in safety features such as force-limiting joints and ISO/TS 15066 compliance. Request product documentation including CAD models, API access details, and electrical schematics for seamless integration into existing production lines.

Production and Customization Capacity

Assess infrastructure maturity through key benchmarks:

- Minimum 3,000m² facility area supporting assembly, testing, and packaging lines

- In-house engineering teams capable of firmware customization and end-effector integration

- Support for color, software, and mechanical modifications (e.g., gripper types, mounting configurations)

Cross-reference listed product volumes with reorder rates and on-time delivery records to assess scalability and consistency.

Quality and Transaction Assurance

Prioritize suppliers demonstrating consistent delivery performance (target ≥98%) and sub-5-hour response times. Verify export experience via transaction histories indicating international shipments. Where available, review customer feedback focusing on post-delivery technical support, calibration accuracy, and system uptime. For high-value procurements, initiate pre-shipment inspections or request video audits of final testing procedures.

What Are the Best Advanced Manufacturing and Robotics Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Shanghai, CN | Conveyors (342), Cargo & Storage Equipment (128), Manipulator (77) | 100% | ≤5h | 100% | US $120,000+ | Yes |

| Changingtek Robotics Technology (Suzhou) Co., Ltd. | Suzhou, CN | Collaborative Robots (66), Articulated Robots (18) | 100% | ≤2h | 33% | US $6,000+ | No |

| Guangzhou Daxiang Technology Development Co., Ltd. | Guangzhou, CN | AGV (312), Other Material Handling Equipment (88) | 100% | ≤2h | 100% | US $4,000+ | No |

| Shenzhen Fider Automation Equipment Co., Ltd. | Shenzhen, CN | Other Industrial Robots (53), Articulated Robots (6) | 100% | ≤2h | 75% | US $90,000+ | No |

| Guangzhou Aobo Robot Technology Co., Ltd. | Guangzhou, CN | Other Commercial Robots (146), Commercial Delivery Robots (68) | - | ≤4h | 100% | - | No |

Performance Analysis

Senad Robot (Shanghai) demonstrates strong ecosystem integration with extensive listings in conveyors and manipulators, backed by a 100% reorder rate and high online revenue, suggesting reliable fulfillment and customer satisfaction. Changingtek Robotics stands out for responsiveness (≤2h) and specializes in 6-axis cobots priced between $7,600–$9,999, targeting mid-tier automation upgrades. Guangzhou Daxiang leads in AGV solutions with 312 active listings, ideal for warehouse logistics automation. Shenzhen Fider focuses on delta-style pick-and-place robots with uniform pricing ($5,180–$6,980/set), indicating standardized production. Guangzhou Aobo targets service-sector deployments with humanoid and delivery robots, showing high retention despite incomplete delivery metrics. Suppliers with verified 100% on-time performance and customization options offer optimal balance for complex integrations.

FAQs

What certifications should robotics suppliers have?

While not all list formal certifications, prioritize suppliers whose products comply with CE standards for electromagnetic compatibility and machinery safety. For deployment in EU or North American facilities, confirm conformity with relevant regional directives. Internal quality controls such as 100% on-time delivery and documented testing protocols serve as practical proxies for ISO 9001-level process discipline.

What is the typical MOQ and lead time?

Minimum order quantities are generally set at 1 unit for robotic systems, facilitating pilot deployments. Lead times range from 15–30 days depending on configuration complexity. Standard models ship faster; customized versions may require additional programming, calibration, or third-party component sourcing, extending delivery by up to two weeks.

Can I request custom programming or mechanical modifications?

Only select suppliers offer customization. Senad Robot (Shanghai) explicitly lists customization options for automation specifications and colors. Others focus on off-the-shelf models. For bespoke requirements—such as specialized end-effectors, communication protocols, or motion paths—engage suppliers early to confirm engineering bandwidth and feasibility assessments.

Do suppliers provide technical documentation and support?

Leading suppliers provide datasheets, installation guides, and basic troubleshooting documentation. Remote support availability varies; those with high reorder rates (e.g., 100%) are more likely to offer sustained technical assistance. Buyers should verify support channels (email, phone, remote desktop) before procurement, especially for cross-border implementations.

How are robotics shipments packaged and exported?

Robotic units are typically crated with foam insulation and moisture barriers to withstand international transit. Export-ready suppliers manage customs documentation and offer FOB or CIF shipping terms. Confirm whether batteries, if included, are shipped separately in compliance with IATA regulations for lithium-powered components.