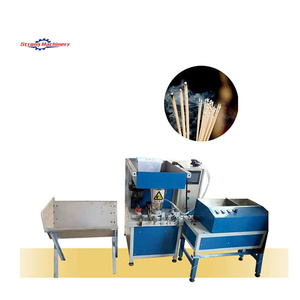

Agarbatti Machine Fully Automatic

1/13

1/13

1/17

1/17

1/15

1/15

1/12

1/12

1/14

1/14

1/31

1/31

About agarbatti machine fully automatic

Where to Find Agarbatti Machine Fully Automatic Suppliers?

China remains the dominant hub for manufacturing fully automatic agarbatti machines, with key production clusters concentrated in Henan province. Zhengzhou, the provincial capital, serves as a central logistics and industrial node, hosting numerous machinery exporters specializing in incense production equipment. These suppliers benefit from vertically integrated supply chains—spanning motor fabrication, stainless steel processing, and control system integration—enabling rapid prototyping and cost-efficient mass production.

The region's mature manufacturing ecosystem supports both standardized and customized machine builds, with many factories operating under ISO-aligned quality management systems. Proximity to raw material sources such as carbon steel coils and electrical components reduces input costs by 15–20% compared to non-specialized regions. Buyers typically experience lead times of 20–40 days for standard configurations, with scalability for bulk orders above 10 sets. The cluster’s infrastructure also facilitates export readiness, with most suppliers experienced in FOB, CIF, and DDP shipping terms for global delivery.

How to Choose Agarbatti Machine Fully Automatic Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Build Quality

Verify machine construction using corrosion-resistant materials (e.g., SUS304 stainless steel) and reputable electrical components (Siemens or Schneider PLCs preferred). Confirm automation level: true fully automatic systems integrate powder mixing, paste extrusion, bamboo stick feeding, drying conveyor integration, and output stacking without manual intervention. Request detailed schematics and operational videos to validate process flow.

Production Capacity Verification

Assess supplier capability through objective metrics:

- Minimum factory area of 1,000m² indicating dedicated production lines

- In-house machining capabilities including CNC cutting, welding, and assembly stations

- Monthly output capacity exceeding 30 units per model

Cross-reference claimed capacity with on-time delivery performance (target ≥98%) and online revenue indicators where available.

Quality Assurance & Transaction Security

Prioritize suppliers providing CE certification or equivalent safety compliance documentation. Demand pre-shipment inspection rights and third-party testing reports for critical functions such as motor endurance and thermal stability. Utilize secure payment mechanisms like trade assurance or escrow services until equipment verification is completed post-delivery. Sample testing is strongly advised—benchmark production speed (sticks/hour), consistency of coating thickness, and downtime frequency before full-scale ordering.

What Are the Best Agarbatti Machine Fully Automatic Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Price (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Joycan Machinery Co., Ltd. | Henan, CN | Incense machines, food processing equipment | US $140,000+ | 100% | ≤7h | 26% | $700 | Limited |

| Zhengzhou Share Machinery Co., Ltd. | Henan, CN | Fully automatic agarbatti machines, multifunctional models | US $420,000+ | 100% | ≤3h | <15% | $1,180 | Yes |

| Henan Tenhui Import & Export Co., Ltd. | Henan, CN | Bamboo and cone incense machines | US $1,000+ | 100% | ≤10h | <15% | $1,000 | Yes |

| Henan Olilang Machinery Co., Ltd. | Henan, CN | Dhoop, round, and square incense machines | US $40,000+ | 86% | ≤2h | <15% | $650 | Limited |

| ZHENGZHOU HONGSHI MACHINERY CO., LTD. | Henan, CN | Tibet-style, reverse-flow, wood-based incense systems | US $250,000+ | 98% | ≤3h | <15% | $1,100 | Yes |

Performance Analysis

Zhengzhou Joycan offers the lowest entry price point at $700 per set, making it suitable for small-scale buyers, though customization options appear limited. Zhengzhou Share Machinery stands out with high responsiveness (≤3h) and strong export volume (US $420,000+), indicating robust international operations. ZHENGZHOU HONGSHI demonstrates engineering specialization with higher-end models targeting niche markets like Tibetan and reverse-flow incense, supported by verified custom manufacturing capabilities. While Henan Olilang provides competitive pricing starting at $650, its 86% on-time delivery rate presents a potential risk for time-sensitive procurement. Suppliers with reorder rates below 15% may indicate lower customer retention, suggesting room for improvement in after-sales service or product reliability.

FAQs

What is the typical MOQ for fully automatic agarbatti machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set, allowing flexibility for trial purchases or small businesses. However, unit pricing becomes more favorable at volumes of 5 sets or more, with discounts averaging 5–12%.

What are common customization options?

Available modifications include adjustable production speed (1,000–5,000 sticks/hour), voltage compatibility (220V/380V/440V), material contact parts (SUS304 vs. carbon steel), and integration with drying tunnels or packaging conveyors. Some suppliers offer OEM branding, color schemes, and control panel language localization.

How long does production and shipping take?

Manufacturing lead time ranges from 20–35 days after order confirmation. Air freight delivery takes 5–10 days but is cost-prohibitive for heavy machinery. Sea freight remains standard, requiring 25–40 days depending on destination port, with additional time for customs clearance.

Do suppliers provide installation and training support?

Support varies by exporter. Mid-to-high-tier suppliers often include remote guidance via video call or manuals. On-site technician deployment is typically offered at an additional cost (USD $150–$250/day plus travel). Confirm training scope and language proficiency prior to purchase.

Are spare parts included with the machine?

Basic packages usually include one set of consumable spare parts (nozzles, brushes, drive belts). Extended warranties or maintenance kits must be requested separately. Ensure availability of replacement components for motors, gearboxes, and control boards before finalizing procurement.