Aluminium Profile Linear Rail

Top sponsor listing

Top sponsor listing

VN

VN

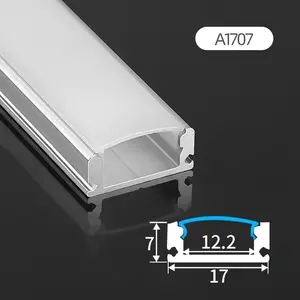

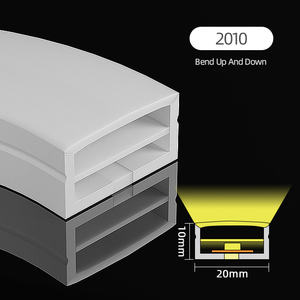

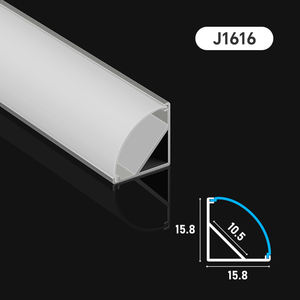

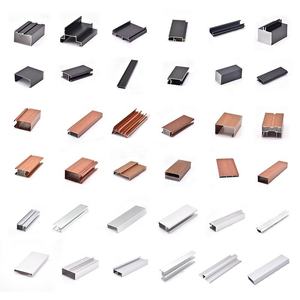

About aluminium profile linear rail

Where to Find Aluminium Profile Linear Rail Suppliers?

China remains the global hub for aluminium profile linear rail manufacturing, with key production clusters in Guangdong, Shandong, and Shanghai. These regions host specialized aluminum extrusion and precision machining facilities that support high-volume output and technical customization. Zhongshan in Guangdong Province is a recognized center for aluminum lighting profiles and structural components, enabling synergies in surface treatment, tooling, and integrated assembly systems. Shandong’s industrial base emphasizes mechanical transmission components, offering access to linear guide shafts, ball screws, and rack gears within close supply proximity.

The concentration of vertically integrated suppliers allows for efficient material flow—from 6063-T5/T6 aluminum billets to finished anodized or powder-coated rails—reducing lead times by up to 25% compared to decentralized sourcing models. Buyers benefit from localized ecosystems where extrusion, CNC machining, anodizing, and quality inspection occur within consolidated zones. Typical advantages include MOQ flexibility (as low as 5 pieces), competitive pricing ($1.50–$75 per unit depending on configuration), and rapid prototyping capabilities supported by digital design validation tools.

How to Choose Aluminium Profile Linear Rail Suppliers?

Selecting reliable suppliers requires systematic evaluation across three core dimensions:

Technical and Material Compliance

Confirm use of standard aluminum alloys such as 6063-T5 or 6063-T6, which provide optimal strength-to-weight ratios and dimensional stability. Verify surface treatments including hard anodizing, sandblasting, or custom color finishes (Pantone-matched) if aesthetic integration is required. For motion-critical applications, demand dimensional tolerance certifications (±0.1mm or tighter) and straightness specifications. While formal ISO 9001 certification is not uniformly declared in available data, prioritize suppliers demonstrating consistent on-time delivery (>98%) and documented quality control processes.

Production and Customization Capacity

Assess supplier capability based on infrastructure indicators:

- Minimum monthly extrusion capacity exceeding 500 meters or 1,000 kilograms

- In-house CNC machining, drilling, tapping, and end-cap fabrication capabilities

- Support for custom profiles via 2D/3D drawings, including load-bearing frame integration and splicing solutions

Cross-reference stated customization options—such as length, width, height, bendability, and mounting clip integration—with actual product listings to validate technical claims.

Transaction Reliability and Responsiveness

Prioritize suppliers with verified response times ≤4 hours and reorder rates above 20%, indicating customer satisfaction and operational consistency. Analyze online transaction volume as a proxy for market presence; top-tier suppliers report annual online revenues exceeding US $300,000. Use sample testing to verify mechanical performance, particularly rail smoothness, bearing compatibility, and structural rigidity under load. Request packaging details—wooden cases, labeling, and moisture protection—to ensure safe international transit.

What Are the Best Aluminium Profile Linear Rail Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Support |

|---|---|---|---|---|---|---|---|

| Zhongshan Xinzheng Aluminum Co., Ltd. | Custom Manufacturer | LED Profile Light, Smart Strip Lights, LED Drivers | 98% | 24% | ≤6h | US $240,000+ | Yes (color, thickness, dimmer cover, splicing, end caps, floor clips, graphics, packaging) |

| Shandong Jingrui Transmission Technology Co., Ltd. | Manufacturer | Linear Guides, Ball Screws, Shaft Systems | 94% | 26% | ≤4h | US $40,000+ | Limited (standard rail configurations) |

| Changsha Hante Metal Material Co., Ltd. | Multispecialty Supplier | Industrial Aluminum Extrusions, C-Beam Rails | 99% | 22% | ≤3h | US $360,000+ | Extensive (anodizing, sandblasting, logo, 3D drawings, drilling, tapping, assembly) |

| Shanghai Dunpin Aluminum Technology Co., Ltd. | Manufacturer | Aluminum Profiles, CNC Linear Rails | 100% | <15% | ≤2h | US $2,000+ | Yes (custom design, T6 temper, extrusion shapes) |

| Shanghai Libei Aluminum Industry Co., Ltd. | Manufacturer | Heavy-Duty Linear Guide Rails, Dual-Axis Systems | - | <15% | ≤7h | US $7,000+ | Yes (built-in bearings, heavy-duty customization) |

Performance Analysis

Changsha Hante and Zhongshan Xinzheng lead in customization breadth and transaction volume, with robust online sales performance and sub-6-hour response times. Shandong Jingrui stands out for mechanical precision, focusing on linear guides and transmission components compatible with industrial automation systems. Shanghai Dunpin achieves perfect on-time delivery despite lower reorder rates, suggesting niche specialization or recent market entry. Buyers seeking high-volume, aesthetically refined rails should prioritize suppliers with demonstrated experience in surface finishing and modular integration. For motion-critical applications, verify compatibility with standard bearing blocks and alignment tolerances before scaling procurement.

FAQs

How to verify aluminium profile linear rail supplier reliability?

Evaluate on-time delivery records (>97% recommended), response speed (≤4h ideal), and transaction history. Request material certifications for aluminum grade (e.g., 6063-T6) and surface treatment durability. Conduct factory audits via video tour to confirm CNC machining capacity and quality inspection protocols.

What is the typical lead time for custom orders?

Standard extrusion and machining lead times range from 15 to 25 days. Complex custom profiles requiring new dies may extend timelines to 35 days. Add 7–14 days for international shipping depending on destination and freight mode.

Can suppliers provide samples?

Most suppliers offer samples at quoted prices, often waiving fees for future bulk orders. Sample costs typically reflect 30–50% of unit production cost, covering material, machining, and handling.

What are common MOQs for aluminium linear rails?

MOQ varies by supplier and product type: ranging from 5 pieces for machined rails to 500 meters or 1,000 kilograms for extruded profiles. Low-volume buyers can negotiate smaller batches with premium pricing.

How are shipments packaged and exported?

Products are typically packed in wooden cases or reinforced cartons with protective film, corner guards, and desiccants. Suppliers with export experience provide FOB or CIF shipping terms and manage documentation for customs clearance in target markets.