Assembly Machine

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About assembly machine

Where to Find Assembly Machine Suppliers?

China remains the global epicenter for assembly machine manufacturing, with key production clusters in Guangdong, Shanghai, and Shandong provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping, high-volume production, and end-to-end customization. Guangdong’s Shenzhen zone specializes in precision automation systems, particularly for battery and electronics assembly, leveraging proximity to semiconductor and power supply component suppliers. Shanghai and Shandong focus on heavy-duty mechanical assembly solutions for woodworking, construction hardware, and industrial packaging lines.

The concentration of technical talent, CNC machining centers, and automated control system integrators within these zones enables efficient coordination across the supply chain. Manufacturers benefit from localized access to raw materials such as stainless steel, aluminum alloys, and PLC components, reducing material lead times by 20–35%. Buyers can expect standard delivery windows of 30–60 days depending on complexity, with established suppliers maintaining buffer inventories for critical subsystems like servo drives and pneumatic modules.

How to Choose Assembly Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Functional Compliance

Verify alignment with applicable industry standards such as CE for European markets or UL/OSHA-compliant safety enclosures where applicable. For customized automation systems, confirm compatibility with required voltage (e.g., 380V industrial three-phase), control interfaces (PLC, HMI brands), and integration capabilities into existing production lines. Suppliers should provide detailed schematics, wiring diagrams, and functional test reports upon request.

Production Capacity Assessment

Evaluate infrastructure maturity using the following benchmarks:

- Facility size exceeding 2,000m² indicating scalable operations

- In-house engineering teams capable of custom design modifications

- Integrated fabrication capabilities including laser cutting, welding, and CNC machining

Cross-reference claimed output capacity with verified online revenue indicators and order fulfillment history. Prioritize suppliers demonstrating consistent on-time delivery rates above 95%.

Customization and After-Sales Support

Confirm scope of customization: color coding, labeling, dimensional adjustments, material substitutions (e.g., food-grade vs. industrial-grade components), and software interface localization. Ensure suppliers offer remote diagnostics, spare parts availability, and technical documentation in English. Video walkthroughs of completed units prior to shipment serve as effective validation tools.

What Are the Best Assembly Machine Suppliers?

| Company Name | Main Products | Verified Type | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Shantou Quanfangwei Machinery Co., Ltd. | Other Packaging Machines, Heat Transfer Machines, Capping Machines | Custom Manufacturer | 100% | <15% | ≤1h | US $30,000+ | Diameter, size, height adjustment (lipstick assembly) |

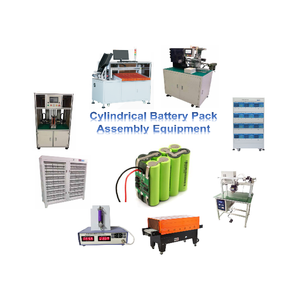

| Shenzhen Sun Laser Technology Co., Ltd. | Battery Pack Production Lines, Lithium-Ion Cell Assembly Systems | Multispecialty Supplier | 100% | 100% | ≤2h | US $60,000+ | Color, material, size, logo, packaging, label, graphic |

| FUTUER CO., LTD | Door Hinge Assembly Machines, Soft-Close Mechanism Automation | Custom Manufacturer | 100% | <15% | ≤2h | US $10,000+ | Color, material, size, logo, packaging, label, graphic |

| Shanghai Win Star Woodworking Machinery Co., Ltd. | Wood Door Frame Press, Furniture Assembly Systems | Multispecialty Supplier | 93% | 25% | ≤3h | US $740,000+ | Material, glue type, roller count, power, width, design, model, photos |

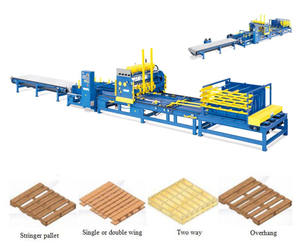

| Qingdao High-Class Service Import & Export Co., Ltd. | Automatic Wooden Pallet Assembly, CNC Block Cutting Systems | Custom Manufacturer | 100% | 25% | ≤1h | US $1,400,000+ | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Shenzhen-based suppliers like Shenzhen Sun Laser Technology demonstrate strong specialization in high-value battery module assembly, supported by EU/CE certification and full-line automation offerings. Their 100% reorder rate reflects deep customer integration and repeat project engagement. In contrast, woodworking-focused manufacturers such as Shanghai Win Star command higher transaction volumes due to broader product portfolios but exhibit slightly longer response cycles.

Manufacturers with sub-2-hour average response times—Shantou Quanfangwei and Qingdao High-Class Service—prioritize export communication efficiency, making them suitable for time-sensitive procurement cycles. While reorder rates below 15% may indicate niche positioning rather than poor service, they often correlate with single-project deployments typical in capital equipment sourcing.

FAQs

How to verify assembly machine supplier reliability?

Validate certifications through official registries and request factory audit reports or video tours confirming in-house production. Analyze historical performance metrics such as on-time delivery, dispute resolution records, and customer retention. Third-party inspection services can be engaged pre-shipment to assess build quality against agreed specifications.

What is the typical minimum order quantity (MOQ)?

Most suppliers set MOQ at one unit or set for assembly machines due to their capital-intensive nature. Exceptions exist for modular components or conveyor subsystems, which may require multi-unit commitments. Bulk orders involving full production lines often trigger price negotiation thresholds starting at three installations.

What customization options are commonly available?

Suppliers routinely offer adjustments in physical dimensions, motor power ratings, control panel languages, safety guarding configurations, and branding elements. Advanced customization includes integration with SCADA systems, RFID tracking, or adaptive tooling for multi-product changeovers. Technical drawings must be finalized and signed off before production commencement.

Do suppliers support global shipping and installation?

Yes, experienced exporters manage international logistics via FOB, CIF, or DDP terms. Sea freight is standard for heavy machinery, while air transport may be used for urgent spare parts. Some suppliers offer optional on-site commissioning support, though associated travel costs are typically borne by the buyer.

What are the average lead times for custom assembly machines?

Standard configurations ship within 30–45 days. Fully customized systems require 50–75 days, including design approval, component sourcing, assembly, and factory acceptance testing. Expedited builds may reduce timelines by 10–15 days at additional cost, subject to resource availability.