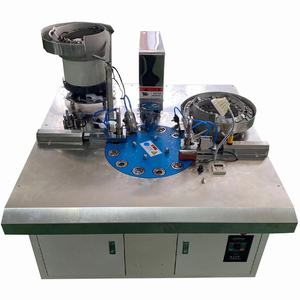

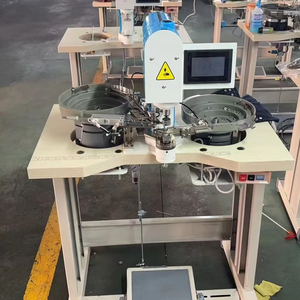

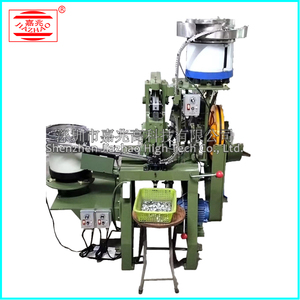

Automatic Fabric Button Making Machine

CN

CN

About automatic fabric button making machine

Where to Find Automatic Fabric Button Making Machine Suppliers?

China remains the global epicenter for automatic fabric button making machine manufacturing, with key production clusters in Zhejiang and Henan provinces. Taizhou in Zhejiang specializes in precision sewing automation equipment, hosting vertically integrated facilities that produce from component casting to final assembly. Henan’s Zhengzhou region has emerged as a hub for industrial apparel machinery, leveraging regional supply chains for servo motors, pneumatic systems, and CNC-machined dies—reducing material procurement cycles by 20–25% compared to non-clustered suppliers.

These industrial ecosystems support rapid prototyping and scalable production, enabling lead times of 15–30 days for standard models. Suppliers benefit from localized access to steel stamping, electronic control units, and motor suppliers within 50km radii, ensuring consistent component quality and faster troubleshooting. The concentration of technical labor—particularly in automation engineering and electromechanical integration—further enhances customization responsiveness. Buyers gain operational advantages including MOQs as low as one set, competitive pricing (ranging $347–$10,000), and compatibility with global voltage standards (110V/220V/380V).

How to Choose Automatic Fabric Button Making Machine Suppliers?

Procurement decisions should be guided by objective evaluation criteria to ensure performance, reliability, and compliance:

Technical Capability Verification

Confirm machine specifications align with production needs: press force (typically 500–1,500N), cycle speed (up to 3,000 buttons/hour), and compatibility with fabric thickness (≤3mm). Verify inclusion of digital controls, programmable logic controllers (PLCs), and safety interlocks. For export markets, CE or CCC certification is essential for regulatory compliance and customs clearance.

Production Infrastructure Assessment

Prioritize suppliers with documented manufacturing capabilities:

- Minimum facility size of 2,000m² to support dedicated assembly lines

- In-house R&D teams focused on automation upgrades and fault diagnostics

- CNC machining and welding capacity for die fabrication and structural components

Cross-reference on-time delivery rates (target ≥94%) and response time (≤4 hours) as indicators of operational efficiency.

Transaction and Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk until post-delivery inspection. Review supplier transaction history, focusing on reorder rates (>15% indicates customer satisfaction) and dispute resolution patterns. Request sample testing to evaluate stitch consistency, button attachment strength, and noise levels under continuous operation (benchmark: ≤75 dB).

What Are the Best Automatic Fabric Button Making Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Taizhou Vma Sewing Machine Co., Ltd. | Zhejiang, CN | Not specified | US $10,000+ | 50% | ≤12h | 50% | 4 models | Limited |

| Henan Penghui Machinery And Equipment Co., Ltd. | Henan, CN | Multispecialty Supplier | US $350,000+ | 98% | ≤3h | <15% | 5 models | Full (color, material, size, logo, packaging) |

| Zhengzhou Hento Machinery Co., Ltd. | Henan, CN | Brand Holder | US $350,000+ | 100% | ≤1h | 18% | 3 models | Full (color, material, size, logo, packaging) |

| Taizhou Yisuo Sewing Machine Co., Ltd. | Zhejiang, CN | Not specified | US $20,000+ | 94% | ≤4h | 15% | 5 models | Limited |

| Zhengzhou Kovi Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $170,000+ | 100% | ≤3h | 15% | 5 models | Full (color, material, size, logo, packaging) |

Performance Analysis

Zhengzhou Hento Machinery leads in reliability with a 100% on-time delivery rate and sub-one-hour average response time, indicating robust internal coordination. Henan Penghui and Zhengzhou Kovi offer extensive customization across material, color, and branding, suitable for OEM partnerships. While Taizhou-based suppliers provide cost-competitive entry-level models (from $347), their lower reorder rates suggest potential gaps in after-sales service or long-term durability. Suppliers with US $170,000+ in online revenue demonstrate export readiness and multilingual support infrastructure. For high-volume buyers, prioritize companies with full automation lines (e.g., 3-head or conveyor-fed models) and PLC-based control systems.

FAQs

How to verify automatic fabric button making machine supplier reliability?

Validate certifications (CE, ISO 9001) through issuing bodies and request test reports for electrical safety and mechanical endurance. Analyze supplier tags for verifiable metrics such as on-time delivery, response time, and reorder rate. Conduct video audits of production lines to confirm automation level and quality inspection processes.

What is the typical sampling timeline?

Sample production takes 7–15 days depending on configuration complexity. Standard models ship within 10 days; customized units require up to 25 days. Air freight adds 5–8 days for international delivery. Some suppliers offer free samples for orders exceeding five units.

Can suppliers ship worldwide?

Yes, established manufacturers manage global logistics via FOB, CIF, or DAP terms. Most support container loading for LCL or FCL shipments and provide export documentation compliant with destination regulations. Sea freight is optimal for bulk orders due to cost efficiency.

Do suppliers offer customization options?

Leading suppliers support full customization including voltage adaptation, color schemes, brand labeling, and PLC interface languages. Custom molds for unique button shapes may incur additional tooling costs ($200–$800) and extend lead time by 10–15 days.

What are common MOQ and pricing structures?

MOQ ranges from 1 set for premium models to 5 sets for budget variants. Prices vary based on automation level: semi-automatic machines start at $4,320, while fully automatic multi-head systems exceed $9,800. Volume discounts typically apply for orders over 10 units.