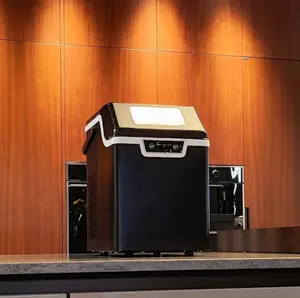

Built In Ice Maker Machine For Home

1/28

1/28

1/12

1/12

1/41

1/41

1/19

1/19

1/11

1/11

1/26

1/26

About built in ice maker machine for home

Where to Find Built-in Ice Maker Machine Suppliers?

China remains the global epicenter for built-in ice maker machine manufacturing, with key industrial clusters in Shanghai, Qingdao, and Ningbo driving production efficiency and export capacity. These regions host vertically integrated supply chains encompassing compressor fabrication, refrigeration system assembly, and stainless steel casing production, enabling streamlined operations. Shanghai and Qingdao specialize in commercial-grade and residential built-in units, leveraging proximity to port infrastructure for rapid international shipment. Ningbo contributes through high-volume OEM/ODM output, particularly for compact and energy-efficient models targeting home use.

The concentration of component suppliers—compressors, evaporators, control panels—within 50km radii reduces logistics overhead and accelerates lead times. Manufacturers benefit from localized access to cold-rolled steel, food-grade plastics, and eco-friendly refrigerants (R600a), supporting compliance with EU and North American environmental standards. Buyers can expect average production lead times of 25–40 days for standard orders, with cost advantages of 20–35% compared to equivalent Western-made units. The ecosystem supports both bulk procurement and low-volume customized builds, making it ideal for distributors, hospitality brands, and private-label ventures.

How to Choose Built-in Ice Maker Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to internationally recognized standards such as CE, RoHS, and ETL, especially for units destined for European or North American markets. While not explicitly stated in all profiles, suppliers with proven export histories often maintain ISO 9001-certified quality management systems. Request test reports for noise levels (typically 38–48 dB), daily ice yield (ranging from 35kg to 100kg per 24 hours), and energy consumption (average 1.2–1.8 kWh/day).

Production & Customization Capability

Assess suppliers based on the following benchmarks:

- Minimum factory area exceeding 3,000m² to ensure scalable output

- In-house engineering teams capable of modifying dimensions, storage capacity, condenser type (air/water-cooled), and user interface design

- Customization options including color finishes, logo branding, packaging, and compressor specifications (e.g., SECOP or Embraco equivalents)

- Ability to integrate under-counter or built-in cabinetry requirements (standard cutout dimensions: 340×600×700mm)

Cross-reference product listings with on-time delivery rates—suppliers achieving ≥97% are more likely to meet scheduled dispatches. Response time under 6 hours indicates strong customer support infrastructure.

Procurement & Risk Mitigation

Utilize secure payment mechanisms such as escrow or letter of credit for initial orders. Prioritize suppliers offering sample units for performance testing, particularly for ice clarity, cycle speed (6–15 minutes per batch), and auto-shutoff functionality. Analyze reorder rates as a proxy for customer satisfaction; rates above 30% suggest consistent quality and service reliability.

What Are the Best Built-in Ice Maker Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | Built-in ice makers, commercial units | US $2,100,000+ | 97% | ≤5h | 15% | 1 set | $136–904.50 |

| Ningbo Younger Crops International Trade Co., Ltd. | Ningbo, CN | Countertop, soft chewable ice makers | US $60,000+ | 75% | ≤9h | 20% | 500–1000 pieces | $30–100 |

| Qingdao Orien Commercial Equipment Co., Ltd. | Qingdao, CN | Built-in, OEM ice makers | Not disclosed | 100% | ≤15h | Not disclosed | 1 unit | $500–900 |

| Shanghai Snowman Electrical Equipment Co., Ltd. | Shanghai, CN | Commercial ice machines | US $40,000+ | 100% | ≤6h | <15% | 1 piece | $378–913 |

| Shanghai Chuangli Refrigeration Equipment Co., Ltd. | Shanghai, CN | CE/ETL-certified ice makers | US $16,000,000+ | 100% | ≤5h | 36% | 5 pieces | $350–970 |

Performance Analysis

Shanghai Chuangli Refrigeration Equipment stands out with the highest reported online revenue (US $16M+) and a 36% reorder rate, indicating strong market confidence and repeat business. The company offers competitive pricing starting at $350/unit with ETL certification and MOQs of 5 pieces, making it suitable for mid-volume buyers seeking certified, reliable units. Shanghai Sihao provides broad product variety and customization depth—including output, material, and graphic options—with flexible 1-set MOQs, ideal for niche or pilot-market entries.

Qingdao Orien and Shanghai Snowman report 100% on-time delivery, reflecting robust production planning, though Orien’s higher price point ($500–900) aligns with premium OEM-focused builds. Ningbo Younger operates at significantly lower price points but imposes large MOQs (500–1000 units) and uses non-standard metrics (“acres”), suggesting potential data inaccuracies or focus on agricultural-sector clients, which may pose risks for traditional home appliance buyers.

FAQs

How to verify built-in ice maker supplier reliability?

Validate certifications through official databases and request third-party inspection reports (e.g., SGS, BV). Examine transaction history, focusing on on-time delivery rates (>97%), response efficiency (<6h), and reorder frequency. Conduct video audits to confirm factory operations and quality control checkpoints.

What is the typical minimum order quantity?

MOQ varies by supplier: companies like Shanghai Sihao and Qingdao Orien accept 1-unit orders, while others require 5–1000 units. Lower MOQs suit startups and testers; high-volume buyers can negotiate better unit pricing at 500+ quantities.

Can suppliers customize built-in ice makers for home use?

Yes, most suppliers offer customization in size, finish, logo, storage bin capacity, and control panel layout. Shanghai-based manufacturers and Qingdao Orien explicitly support OEM/ODM modifications, including integration with kitchen cabinetry and quiet operation modes.

What are common lead times and shipping options?

Standard production lead time ranges from 25–40 days post-deposit. Sea freight (FCL/LCL) is optimal for bulk orders, reducing costs by up to 60% versus air shipping. Air freight delivers in 7–12 days but is recommended only for samples or urgent replenishments.

Do suppliers provide product samples?

Most suppliers offer samples at full or partial cost, typically refundable upon subsequent bulk order. Sample pricing ranges from $150–900 depending on model complexity. Allow 10–18 days for production and 5–10 days for international delivery.