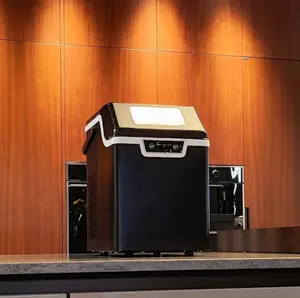

Built In Ice Maker For Home

1/28

1/28

1/41

1/41

1/19

1/19

1/26

1/26

1/11

1/11

1/8

1/8

1/18

1/18

About built in ice maker for home

Where to Find Built-in Ice Maker for Home Suppliers?

China remains the global epicenter for built-in ice maker manufacturing, with key production clusters concentrated in Shanghai, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, stainless steel stamping, refrigeration system assembly, and final product testing. Shanghai-based suppliers benefit from proximity to R&D centers and international ports, enabling faster export cycles—typically 25–40 days for containerized shipments. The Pearl River Delta, including Dongguan and Cixi, leverages dense networks of component manufacturers, reducing material procurement lead times by up to 30% compared to offshore alternatives.

Industrial ecosystems in these zones support both high-volume standard production and low-volume customization. Facilities commonly integrate CNC machining, automated welding, and environmental simulation chambers for performance validation under variable ambient conditions. Buyers gain access to scalable output, with leading suppliers reporting monthly capacities exceeding 10,000 units. Cost efficiencies are further enhanced by localized sourcing of core components such as rotary compressors, evaporators, and control boards, contributing to 18–25% lower unit costs versus Western or Southeast Asian producers.

How to Choose Built-in Ice Maker for Home Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation protocols focused on technical compliance, production scalability, and transaction security.

Technical Compliance

Verify adherence to international safety and performance standards, including CE, ETL, RoHS, and ISO 9001. For North American markets, ETL listing is essential for regulatory acceptance and insurance compliance. Demand test reports validating energy consumption (e.g., DOE-compliant measurements), noise levels (typically ≤45 dB), and daily ice yield accuracy under controlled conditions (24°C/70°F ambient temperature).

Production Capability Audits

Assess operational infrastructure through documented verification:

- Minimum factory area of 3,000m² to ensure dedicated production lines

- In-house engineering teams capable of customizing dimensions, condensation type (air/water-cooled), storage capacity, and interface design

- On-site quality control stations conducting leak tests, electrical safety checks, and cycle endurance validation

Cross-reference self-reported data with verified metrics such as on-time delivery rates (>97%) and reorder frequency to assess reliability.

Transaction Safeguards

Utilize secure payment mechanisms like escrow services to mitigate risk during initial transactions. Prioritize suppliers with transparent order tracking, documented QC processes, and willingness to provide pre-shipment inspection access. Request functional samples to evaluate build quality, ice formation speed, and user interface responsiveness before committing to bulk orders.

What Are the Best Built-in Ice Maker for Home Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Customization Options | Key Products |

|---|---|---|---|---|---|---|---|---|

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | US $2,100,000+ | 97% | ≤4h | 15% | 1 set/piece | Yes (color, size, logo, material, storage capacity) | Built-in electric ice makers, commercial-grade units |

| Shanghai Snowman Electrical Equipment Co., Ltd. | Shanghai, CN | US $40,000+ | 100% | ≤6h | <15% | 1 piece | Limited | Stainless steel automatic ice machines |

| Shanghai Chuangli Refrigeration Equipment Co., Ltd. | Shanghai, CN | US $16,000,000+ | 100% | ≤5h | 34% | 5 pieces | Yes (color, material, logo, packaging) | CE/ETL-certified home and commercial ice makers |

| Cixi Jirui Electric Appliance Co., Ltd. | Zhejiang, CN | US $2,000+ | 50% | ≤7h | <15% | 2–10 pieces | Limited | Energy-efficient built-in and freestanding models |

| Dongguan Strong Construction Machinery Co., Ltd. | Guangdong, CN | US $50,000+ | 100% | ≤3h | 23% | 1 unit/set | Yes (custom air-cooling configurations) | Compact household and commercial ice-making machines |

Performance Analysis

Shanghai Chuangli leads in customer retention (34% reorder rate) and revenue volume, indicating strong market trust and consistent output quality. Despite higher MOQs (5 pieces), its certification portfolio and customization flexibility make it ideal for branded distributors and B2B clients. Shanghai Sihao offers competitive pricing starting at $173/unit and extensive OEM capabilities, supported by a robust delivery record. Dongguan Strong distinguishes itself with sub-3-hour response times and full on-time fulfillment, appealing to time-sensitive buyers. In contrast, Cixi Jirui’s 50% on-time delivery rate presents a significant operational risk despite low entry pricing ($39–45 range). Buyers seeking premium residential integration should prioritize suppliers offering ETL/CE certifications and precision-fit dimensional controls.

FAQs

How to verify built-in ice maker supplier reliability?

Validate certifications through official databases (e.g., IAPMO for ETL, TÜV for CE). Request third-party inspection reports from entities like SGS or Bureau Veritas covering electrical safety, refrigerant integrity, and structural durability. Analyze buyer feedback focusing on post-delivery support, defect resolution timelines, and consistency across batches.

What is the average sampling timeline?

Standard sample production takes 10–20 days, depending on customization level. Units requiring specific voltage (110V/220V) or嵌入式尺寸 (standard cabinet cutouts) may require 25–35 days. Air freight adds 5–10 days for global delivery.

Can suppliers ship built-in ice makers worldwide?

Yes, most established manufacturers offer FOB, CIF, and DDP shipping terms. Confirm compliance with destination regulations—particularly for refrigerants (e.g., R600a restrictions in certain EU countries) and electrical standards. Sea freight is optimal for full-container loads (15–20ft), while express courier suits sample or small-lot deliveries.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for future bulk commitments (e.g., 50+ units), while others charge 50–70% of unit cost, refundable upon order placement. Expect sample prices between $150–$400 depending on model complexity.

How to initiate customization requests?

Submit detailed specifications including installation type (built-in/freestanding), width/height/depth constraints, ice production rate (kg/24h), condenser type, power supply, and desired finish (stainless steel, panel-ready). Leading suppliers respond with CAD drawings within 72 hours and deliver prototypes in 3–5 weeks.