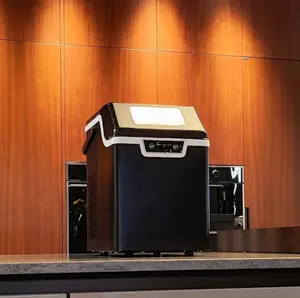

Built In Ice Makers For Home Use

Top sponsor listing

Top sponsor listing

1/12

1/12

1/27

1/27

1/28

1/28

1/24

1/24

1/16

1/16

1/26

1/26

1/10

1/10

1/25

1/25

1/7

1/7

1/26

1/26

1/8

1/8

1/22

1/22

About built in ice makers for home use

Where to Find Built-in Ice Makers for Home Use Suppliers?

China remains a dominant hub for manufacturing built-in ice makers for home use, with key production clusters concentrated in Zhejiang and Anhui provinces. These regions host vertically integrated supply chains that streamline component sourcing—particularly compressors, evaporators, and stainless steel enclosures—reducing unit costs by 15–25% compared to non-specialized manufacturers. Yuyao and Ningbo in Zhejiang province are recognized for high-volume appliance production, supported by mature logistics networks enabling efficient export via Ningbo Port, one of the world’s busiest container terminals.

Suppliers in these industrial zones benefit from localized access to sheet metal fabrication, injection molding, and refrigeration system assembly, allowing for rapid prototyping and scalable production. Average monthly output for mid-tier suppliers ranges from 5,000 to 15,000 units, with lead times typically between 25–40 days for bulk orders. The ecosystem supports both standardized models and OEM/ODM configurations, making it ideal for importers targeting residential kitchen appliances in North America, Europe, and Southeast Asia.

How to Choose Built-in Ice Makers for Home Use Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Compliance Verification

Confirm adherence to international safety and performance standards such as CE, RoHS, and UL listings where applicable. For home-use appliances, validate electrical compliance (110V–240V compatibility) and refrigerant type (e.g., R600a for low environmental impact). Request test reports for noise levels (ideally ≤45 dB), daily ice yield (typically 12–35 kg/day), and energy consumption (average 0.8–1.2 kWh/24h).

Production Capability Assessment

Evaluate core manufacturing competencies through the following indicators:

- Facility size exceeding 3,000m² to support continuous production lines

- In-house engineering teams capable of supporting custom designs (e.g., panel integration, water inlet systems)

- Integration of automated welding, foam insulation injection, and leak testing stations

Cross-reference on-time delivery rates (target ≥95%) and reorder rates (<20% suggests limited customer retention issues) to assess reliability.

Customization and Transaction Safeguards

Prioritize suppliers offering configurable options including finish materials (stainless steel, black glass), control interfaces (LED touch panels), and dimensional adaptability for standard cabinet cuts (typically 15"–24" widths). Verify packaging specifications (double-layer cartons with EPS foam) to minimize transit damage. Utilize secure payment mechanisms such as trade assurance or letter of credit, and insist on pre-shipment inspections (PSI) for first-time orders.

What Are the Best Built-in Ice Makers for Home Use Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Yuyao Haohong Electrical Appliance Co., Ltd. | Ice Makers, Compact Refrigerators, Car Refrigerators | US $180,000+ | 100% | <15% | ≤2h | Limited | Not specified | Not listed |

| Ningbo Younger Crops International Trade Co., Ltd. | Ice Makers, Slush Machines, Countertop Units | US $60,000+ | 100% | 20% | ≤10h | Color, material, size, logo, packaging | 500–1,000 units | $30–$100 |

| Cixi Jirui Electric Appliance Co., Ltd. | Commercial & Home Ice Makers, Ice Crushers, Blenders | US $3,000+ | 75% | <15% | ≤6h | Limited | 2 pieces | $185–$600 |

| Hefei Interchina Corporation | Ice Cream Makers, Microwaves, Air Fryers | US $200+ | 100% | - | ≤12h | OEM available | 300 pieces | $49–$129 |

| Ningbo Hicon Industry Technology Co., Ltd. | Built-in, Portable, Nugget Ice Makers | US $1,000+ | 100% | <15% | ≤8h | Pipe length, tank size, plug type, color, panel design | 2–500 units | $46–$390 |

Performance Analysis

Yuyao Haohong demonstrates strong operational consistency with a 100% on-time delivery rate and high online revenue, indicating robust order management despite limited customization offerings. Ningbo Younger stands out for flexibility, supporting full branding and design modifications with competitive MOQs starting at 500 units. Cixi Jirui offers higher-priced commercial-grade units but shows lower delivery reliability (75%), suggesting potential bottlenecks in fulfillment. Hefei Interchina provides budget-friendly options with minimal response delays, though its broader product focus may dilute specialization. Ningbo Hicon excels in configurability and low MOQs, ideal for niche market testing or boutique kitchen integrations.

FAQs

How to verify built-in ice maker supplier reliability?

Validate certifications (CE, RoHS) through official databases and request factory audit reports or video walkthroughs of production lines. Analyze transaction metrics such as on-time delivery rate, response time, and reorder frequency. Third-party inspection services can verify product conformity before shipment.

What is the typical minimum order quantity (MOQ)?

MOQs vary significantly: mass producers often require 500–1,000 units, while specialized or custom-focused suppliers like Ningbo Hicon accept as few as 2–50 pieces. Smaller batches typically incur higher per-unit costs.

Do suppliers offer OEM/ODM services?

Yes, multiple suppliers—including Ningbo Younger and Ningbo Hicon—support OEM labeling, color finishes, control panel graphics, and packaging customization. Lead time for custom tooling is typically 15–25 days.

What are common lead times and shipping methods?

Production lead time averages 30–40 days after deposit confirmation. Sea freight (FCL/LCL) is standard for bulk shipments, with air freight reserved for samples or urgent orders (7–10 days transit).

Are samples available before bulk ordering?

Most suppliers provide paid samples, typically priced at 1.5–2x unit cost, with shipping fees applicable. Sample production takes 7–14 days. Costs may be credited toward future orders exceeding agreed thresholds.