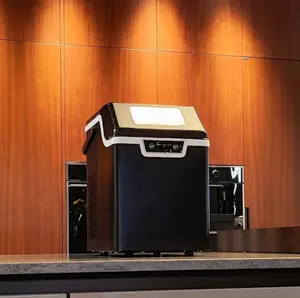

Home Built In Ice Maker

Top sponsor listing

Top sponsor listing

About home built in ice maker

Where to Find Home Built-In Ice Maker Suppliers?

China remains the global epicenter for home built-in ice maker manufacturing, with key production clusters in Zhejiang and Shanghai offering specialized capabilities. Ningbo and Shanghai host concentrated ecosystems of appliance manufacturers that integrate advanced refrigeration engineering with consumer-grade design. These regions benefit from mature supply chains for compressors, evaporators, and food-safe plastics, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian producers.

The industrial clusters support vertical integration across R&D, injection molding, sheet metal fabrication, and final assembly, allowing suppliers to maintain tight control over quality and lead times. Proximity to Shanghai Port and Ningbo-Zhoushan Port ensures efficient export logistics, with standard sea freight transit times of 18–25 days to North America and Europe. Buyers gain access to facilities capable of monthly outputs ranging from 5,000 to over 50,000 units, depending on model complexity and customization level.

How to Choose Home Built-In Ice Maker Suppliers?

Procurement decisions should be guided by objective evaluation criteria focused on technical capability, compliance, and transaction reliability.

Technical and Quality Compliance

Verify adherence to international safety and performance standards such as CE, RoHS, and UL. For residential appliances, compliance with IEC 60335 (household electrical safety) is essential. Demand documentation for compressor efficiency ratings, condensation management systems, and material food-contact certifications. Suppliers serving EU or North American markets must demonstrate conformity with regional energy labeling requirements.

Production and Customization Capacity

Assess supplier infrastructure through the following benchmarks:

- Minimum factory area of 3,000m² for dedicated production lines

- In-house capabilities in sheet metal stamping, plastic injection molding, and refrigerant charging

- Customization support for color finishes, control panel interfaces, logo branding, and dimensional adjustments

Cross-reference product listings with stated customization options and verify output capacity against order volume requirements.

Transaction and Risk Mitigation

Prioritize suppliers with verifiable on-time delivery rates exceeding 97% and response times under 6 hours. Utilize secure payment mechanisms such as escrow services or letters of credit. Conduct pre-shipment inspections via third-party agencies like SGS or TÜV to validate unit functionality, structural integrity, and packaging durability. Request samples to evaluate noise levels (typically 35–45 dB), ice production rate (measured in kg/24h), and user interface clarity before mass production.

What Are the Best Home Built-In Ice Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Ningbo Konwin Electrical Appliance Co., Ltd. | Ice Makers, Electric Heaters, Air Coolers | US $2,000,000+ | 100% | ≤3h | 33% | Color, size, logo, packaging, label, graphic, material | 1000 pieces | $30–$80 |

| Ningbo Younger Crops International Trade Co., Ltd. | Ice Makers, Countertop Appliances | US $60,000+ | 100% | ≤9h | 20% | Color, material, size, logo, packaging, label, graphic | 500–1000 pieces | $30–$100 |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Commercial & Home Ice Makers | US $1,800,000+ | 98% | ≤4h | 17% | Color, size, packaging, output, compressor, storage capacity, dimensions | 1 set/piece | $189–$325 |

| Shanghai Snowman Electrical Equipment Co., Ltd. | Commercial Ice Machines | US $10,000+ | 100% | ≤6h | <15% | Limited public data | 1 piece | $378–$900 |

| Hefei Interchina Corporation | Ice Cream Makers, Microwaves, Juicers | US $200+ | 100% | ≤13h | - | Limited customization visibility | 300–1000 pieces | $14–$92 |

Performance Analysis

Ningbo Konwin stands out for high-volume production capability, extensive customization options, and strong reorder metrics (33%), indicating consistent buyer satisfaction. Its broad product portfolio suggests robust manufacturing flexibility. Shanghai Sihao offers lower MOQs (single-unit orders) and detailed technical configurability, making it suitable for niche or prototype-driven buyers despite a slightly lower on-time delivery rate (98%).

Ningbo-based suppliers demonstrate superior responsiveness, with two companies achieving sub-9-hour average reply times and 100% on-time fulfillment. Suppliers with US $1M+ annual online revenue—Konwin and Sihao—show greater operational scale and digital engagement maturity. Hefei Interchina, while exhibiting competitive pricing, lacks reorder rate transparency and has limited response speed, suggesting potential constraints in post-sales support or production scalability.

FAQs

How to verify home built-in ice maker supplier reliability?

Cross-check claimed certifications with official databases. Request evidence of quality management systems (e.g., ISO 9001). Analyze customer reviews focusing on long-term equipment reliability, refrigerant leak incidents, and after-sales service responsiveness. Conduct virtual factory audits to observe production line organization and QC checkpoints.

What is the typical lead time for bulk orders?

Standard lead times range from 30 to 45 days after deposit confirmation, depending on order size and customization depth. Pre-production sampling takes 7–14 days. Expedited production may reduce timelines by 10–15 days at additional cost.

Do suppliers offer OEM/ODM services?

Yes, most established suppliers provide OEM branding (logo, packaging) and ODM modifications (size, capacity, control interface). Minimum order thresholds typically start at 1,000 units for full customization, though some accept 500-unit orders for minor adaptations.

What are common MOQ and pricing structures?

MOQs vary: mass-market models require 500–1,000 units, while commercial-grade or customized units may allow single-piece orders at higher per-unit costs. Prices range from $30 for compact countertop models to over $800 for high-capacity built-in units with premium finishes and compressors.

How to manage logistics and import compliance?

Confirm FOB or CIF shipping terms and ensure packaging meets ISTA 3A standards for vibration and drop resistance. Verify that units carry required voltage/frequency ratings (e.g., 110V/60Hz for North America). Refrigerant-filled models must comply with local environmental regulations (e.g., EPA Section 608 in the U.S.). Sea freight is optimal for containerized shipments; air freight suits urgent sample deliveries.