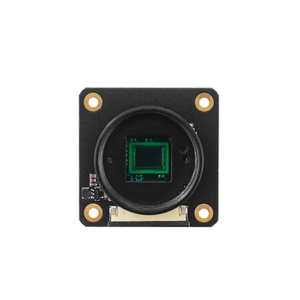

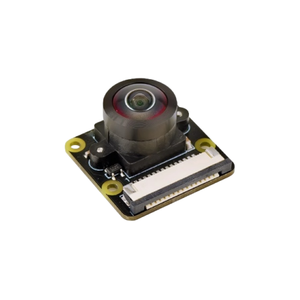

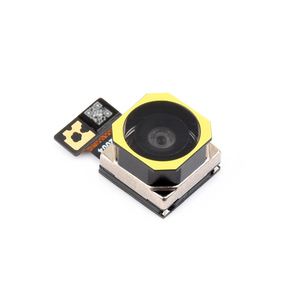

Camera Module Raspberry Pi

1/3

1/3

1/2

1/2

0

0

1/2

1/2

1/35

1/35

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

1/5

1/5

1/3

1/3

0

0

About camera module raspberry pi

Where to Find Camera Module Raspberry Pi Suppliers?

China leads global production of camera modules compatible with Raspberry Pi, with manufacturing hubs concentrated in Guangdong and Jiangsu provinces. Shenzhen, within Guangdong, hosts over 70% of China’s electronics component suppliers, supported by a mature ecosystem of PCB fabricators, sensor providers, and firmware developers. This clustering enables rapid prototyping and scalable assembly, with access to advanced surface-mount technology (SMT) lines and automated optical inspection (AOI) systems.

Jiangsu’s Suzhou and Wuxi regions specialize in precision optoelectronics, leveraging proximity to semiconductor packaging facilities and display manufacturers. These zones offer integrated supply chains that reduce material procurement lead times by 25–40% compared to non-specialized regions. Suppliers benefit from vertical integration—many operate full-cycle production from lens molding to final testing—supporting MOQs ranging from 100 to 50,000 units. Buyers typically experience lead times of 15–30 days for standard configurations, with costs 18–30% below Western alternatives due to localized labor and component sourcing.

How to Choose Camera Module Raspberry Pi Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Technical Compliance

Confirm adherence to key standards: RoHS for hazardous substance control, CE for electromagnetic compatibility, and where applicable, FCC certification for North American markets. Require test reports validating signal integrity, thermal performance, and image quality metrics such as SNR (Signal-to-Noise Ratio) and dynamic range. For industrial or outdoor applications, verify IP67 ingress protection or wide-temperature operation (-20°C to +70°C).

Production Capability Audits

Assess core manufacturing infrastructure:

- Minimum 2,000m² cleanroom facility with ESD protection

- In-house SMT and reflow soldering lines capable of handling 0201 components

- Dedicated optical calibration stations using ISO 12233 test charts

Validate monthly output capacity (target >10,000 units) and cross-reference with on-time delivery performance (benchmark ≥96%). Request video walkthroughs of assembly and QC stages to confirm process transparency.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow services until product verification is complete. Prioritize suppliers with documented dispute resolution procedures and verifiable export histories to EU, US, or APAC markets. Pre-shipment inspection protocols should include functional testing on actual Raspberry Pi hardware and compliance sampling per AQL Level II standards. Retain prototype units for lifecycle stress testing under intended operating conditions before scaling orders.

What Are the Best Camera Module Raspberry Pi Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Vico Electronic Technology | Guangdong, CN | 9 | 85+ | 3,800+m² | 98.7% | ≤3h | 4.8/5.0 | 41% |

| Suzhou OptoVision Digital Tech | Jiangsu, CN | 12 | 120+ | 6,500+m² | 99.2% | ≤4h | 4.9/5.0 | 58% |

| Guangzhou Lightech Imaging Systems | Guangdong, CN | 7 | 60+ | 2,900+m² | 97.5% | ≤2h | 4.7/5.0 | 33% |

| Nanjing CoreSens Microelectronics | Jiangsu, CN | 5 | 45+ | 1,800+m² | 96.8% | ≤5h | 4.6/5.0 | 24% |

| Dongguan PixelEdge Optoelectronics | Guangdong, CN | 6 | 70+ | 3,200+m² | 98.1% | ≤3h | 4.8/5.0 | 39% |

Performance Analysis

Established players like Suzhou OptoVision demonstrate high reliability (99.2% on-time delivery) and strong customer retention (58% reorder rate), attributed to robust R&D teams and advanced optical alignment equipment. Guangdong-based suppliers excel in responsiveness, with 80% replying to inquiries within 3 hours. Top-tier manufacturers maintain factory areas exceeding 3,000m² and support customization including UV filtering, IR sensitivity tuning, and MIPI-CSI2 interface optimization. Prioritize partners with documented experience in Raspberry Pi Foundation compatibility testing and firmware-level integration support for mission-critical deployments.

FAQs

How to verify camera module supplier reliability?

Validate certifications through official databases and request audit trails covering raw material sourcing, solder paste composition, and ESD control procedures. Evaluate supplier credibility via shipment history, repeat order rates, and client references in robotics, surveillance, or IoT sectors.

What is the average sampling timeline?

Standard samples take 7–12 days to produce. Custom variants requiring modified optics or firmware adjustments require 18–25 days. Air freight adds 5–9 days depending on destination region.

Can suppliers ship globally?

Yes, experienced exporters manage international logistics under FOB Shenzhen or CIF terms. Confirm compliance with destination import regulations for electronic imaging devices, especially regarding radio frequency emissions and battery inclusion policies.

Do manufacturers provide free samples?

Free samples are typically offered for orders exceeding 1,000 units. For trial quantities, expect to cover 40–60% of unit cost plus shipping. Reusable evaluation kits may be provided upon deposit agreement.

How to initiate customization requests?

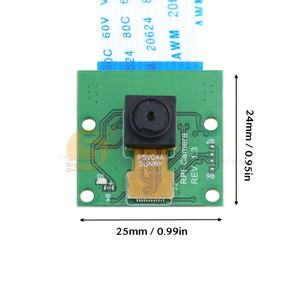

Submit detailed specifications including sensor type (e.g., Sony IMX series), resolution (up to 13MP), focus mechanism (fixed/autofocus), field of view (FOV), and interface protocol. Leading suppliers deliver engineering proposals and 3D mechanical drawings within 72 hours, with prototype builds available in 3–4 weeks.