Raspberry Pi Camera 2

1/11

1/11

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/2

1/2

1/2

1/2

1/5

1/5

1/3

1/3

1/3

1/3

1/31

1/31

0

0

1/6

1/6

1/3

1/3

1/3

1/3

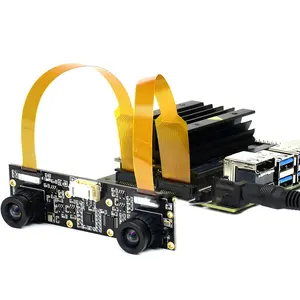

About raspberry pi camera 2

Where to Find Raspberry Pi Camera 2 Suppliers?

Global production of the Raspberry Pi Camera 2 and compatible variants is primarily concentrated in electronics manufacturing hubs across southern China, particularly in Guangdong and Jiangsu provinces. These regions host integrated supply chains encompassing semiconductor packaging, printed circuit board (PCB) fabrication, and precision optics assembly, enabling rapid prototyping and scalable production. Shenzhen, within Guangdong, serves as a core node due to its proximity to component suppliers and advanced SMT (surface-mount technology) facilities capable of handling high-density sensor modules.

The industrial ecosystem supports both OEM/ODM configurations and drop-in replacements for the original Raspberry Pi Foundation design. Manufacturers leverage vertical integration—combining lens sourcing, image sensor bonding, and firmware calibration—to reduce lead times and maintain consistent output quality. Buyers benefit from localized logistics networks that support air and sea freight consolidation, with typical export processing cycles ranging from 15 to 30 days for batch orders. Cost efficiencies stem from mature subcontractor networks, where secondary operations such as conformal coating, ESD testing, and automated optical inspection (AOI) are readily accessible within 30km radii of major assembly sites.

How to Choose Raspberry Pi Camera 2 Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical compliance, production integrity, and transaction security.

Technical Compliance

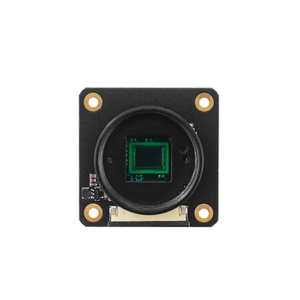

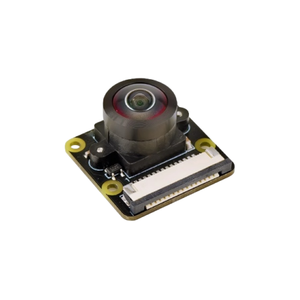

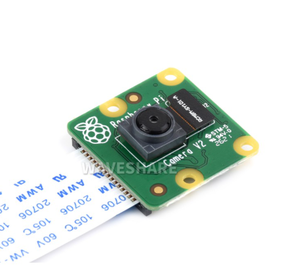

Confirm adherence to RoHS and REACH environmental directives as baseline requirements. For applications involving industrial automation or outdoor deployment, verify IP67 ingress protection ratings and operating temperature ranges (-20°C to +70°C). Demand test reports for key performance indicators: resolution accuracy (8MP Sony IMX219 sensor compliance), low-light sensitivity (minimum 1.12µm pixel size), and field-of-view consistency (typically 62° diagonal). Firmware compatibility with Raspberry Pi OS and libcamera frameworks must be documented.

Production Capability Audits

Assess operational scale and process control through the following benchmarks:

- Minimum 2,000m² cleanroom-integrated facility for ESD-safe assembly

- In-house SMT lines with placement accuracy ≤±0.05mm for fine-pitch components

- Dedicated QC stations performing dark-room imaging tests and focus calibration

Correlate factory size with order fulfillment history; suppliers supporting monthly outputs above 50,000 units typically maintain >95% on-time delivery rates.

Transaction Safeguards

Utilize secure payment mechanisms such as irrevocable LC or escrow services for initial transactions. Request sample units prior to bulk ordering to validate image quality, solder joint integrity, and connector durability. Verify export experience through shipping documentation—prefer suppliers with established DDP/DDU capabilities to North America, EU, and APAC regions. Prioritize partners providing traceability via batch numbering and 12-month warranty coverage.

What Are the Best Raspberry Pi Camera 2 Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In the absence of specific supplier data, procurement strategies should emphasize verification over volume metrics. While larger manufacturers offer economies of scale, mid-tier suppliers with specialized optoelectronic expertise often deliver higher consistency in autofocus calibration and color fidelity. Responsiveness remains a strong indicator of service orientation, with top-tier vendors typically replying to technical inquiries within 4 hours. For mission-critical deployments, prioritize suppliers who provide full BOM transparency, including sensor lot tracking and conformal coating certification. Customization feasibility—such as IR-filter removal, extended ribbon cables, or waterproof housing integration—should be validated through pre-production samples and photometric testing.

FAQs

How to verify Raspberry Pi Camera 2 supplier reliability?

Cross-validate certifications (ISO 9001, IATF 16949 if automotive-grade) with accredited bodies. Request evidence of functional testing protocols, including SNR analysis, chromatic aberration checks, and thermal cycling results. Review customer feedback focusing on defect rates, firmware update support, and responsiveness to RMA requests.

What is the average sampling timeline?

Standard samples are typically dispatched within 7–10 working days post-order confirmation. Custom modifications—such as alternative lens mounts (CS/M12), monochrome sensors, or global shutter variants—require 18–25 days for prototype development and validation.

Can suppliers ship globally?

Yes, most established manufacturers support international shipping under FOB Shenzhen, CIF, or DDP terms. Ensure compliance with destination regulations regarding electronic imports, especially for battery-equipped or wireless-enabled variants. Air freight enables delivery within 5–7 days; sea freight is economical for containerized orders exceeding 5,000 units.

Do manufacturers provide free samples?

Sample policies vary. First-time buyers generally cover sample costs and shipping. Fee waivers may apply upon confirmation of volume orders (e.g., ≥1,000 units). Recurring clients often receive complimentary evaluation units for new revisions.

How to initiate customization requests?

Submit detailed specifications including desired interface type (MIPI CSI-2), focal length (2.5mm–6mm), spectral response range, and mechanical constraints. Reputable suppliers will respond with engineering drawings, Gerber files, and test plans within 72 hours. Prototype iterations are typically completed within three weeks, followed by PPAP-level approval for mass production.