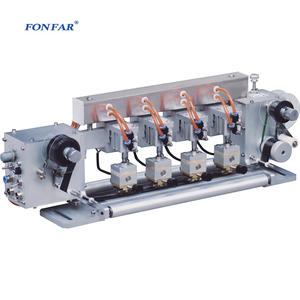

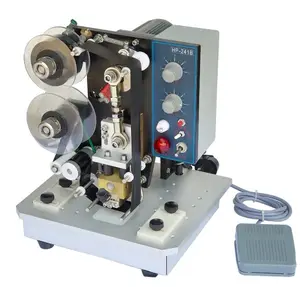

Carton Coding Machine

Top sponsor listing

Top sponsor listing

CN

CN

About carton coding machine

Where to Find Carton Coding Machine Suppliers?

China remains the central hub for carton coding machine manufacturing, with key production clusters in Henan, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production. Dongguan and Shenzhen in Guangdong specialize in intelligent coding systems, including handheld CIJ (Continuous Inkjet) and thermal transfer printers, leveraging proximity to electronics component suppliers. Wenzhou in Zhejiang focuses on mechanical coding and packaging line integration, offering cost-efficient solutions for batch date printing and barcode labeling on cartons.

The industrial ecosystems in these zones enable streamlined access to CNC machining, laser cutting, and injection molding services within 50km radii, reducing component lead times by up to 40%. Suppliers benefit from localized material sourcing—particularly stainless steel, aluminum alloys, and polymer-based ink delivery systems—achieving 15–25% lower production costs compared to non-specialized manufacturers. Average order fulfillment spans 15–30 days for standard models, with customization lead times extending to 35–45 days depending on technical complexity.

How to Choose Carton Coding Machine Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation across three core dimensions:

Technical Capability & Compliance

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For export-bound equipment, confirm compatibility with regional voltage standards (e.g., 110V/60Hz for North America). Assess product specifications for print resolution (measured in dpi), character height range (typically 2–20mm), and supported substrates (corrugated cardboard, coated paperboard, plastic film).

Production Infrastructure Assessment

Prioritize suppliers demonstrating measurable operational scale and engineering capacity:

- Facility size exceeding 2,000m² indicating dedicated assembly lines

- In-house R&D teams focused on nozzle design, ink formulation, or software interface development

- Integration capabilities for conveyor systems and automated production lines

Cross-reference on-time delivery rates (target ≥95%) and response times (≤2 hours) as proxies for operational efficiency and customer service reliability.

Transaction Risk Mitigation

Utilize secure payment frameworks with milestone-based disbursements tied to production progress. Require sample testing under real-world conditions—evaluate print clarity after 72-hour humidity exposure and verify resistance to smudging or fading. Confirm warranty terms (standard: 12 months) and availability of technical support for installation and troubleshooting.

What Are the Best Carton Coding Machine Suppliers?

| Company Name | Location | Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xinxiang New Bell Information Materials Co., Ltd. | Henan, CN | Custom Manufacturer | US $100,000+ | 97% | ≤1h | 17% | Coding Machines, Printer Ribbons, Stamping Foils | Label nozzle, toner, graphic logo, material size |

| Wenzhou Qingyu Machinery Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $90,000+ | 91% | ≤4h | 40% | Coding, Sealing, Labeling, Filling Machines | Limited; primarily mechanical configuration |

| Dongguan Sammi Packing Machine Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $380,000+ | 88% | ≤2h | <15% | Semi-Automatic & Desktop Coders, Batch Printers | Font height, machine type, bag/box size |

| Shenzhen Wutong Technology Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $250,000+ | 95% | ≤3h | <15% | Handheld CIJ, Portable Sublimation, High-Speed Printers | Color, logo, label layout, packaging design |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | Multispecialty Supplier | US $40,000+ | 95% | ≤3h | <15% | Inkjet Printers, Laser Markers, Automatic Coders | Material compatibility, drying speed, ink type |

Performance Analysis

Wenzhou Qingyu stands out with a 40% reorder rate, suggesting strong customer satisfaction in mechanical reliability and post-sale service. Despite slightly lower on-time delivery (91%), its integration into broader packaging lines enhances value for buyers seeking turnkey solutions. Xinxiang New Bell demonstrates high responsiveness (≤1h) and robust customization in consumables like ribbons and toners, making it ideal for clients requiring brand-specific print outputs. Shenzhen Wutong and Wuhan Willita offer advanced digital coding technologies, particularly in handheld and TIJ (Thermal Inkjet) systems, though their sub-15% reorder rates may indicate room for improvement in long-term client retention. Dongguan Sammi leads in revenue volume but lags in delivery performance, warranting closer scrutiny of production scheduling before large-scale orders.

FAQs

How to verify carton coding machine supplier reliability?

Validate certifications through official registries and request factory audit reports or video walkthroughs of production floors. Analyze transaction histories focusing on dispute resolution outcomes and shipment consistency. Third-party inspection services can verify build quality against agreed technical specifications prior to dispatch.

What is the typical MOQ and pricing range?

Standard MOQ is 1 set for most suppliers, with prices ranging from $35 for basic manual coders to $850 for multi-head automatic systems. Bulk orders (≥10 units) often qualify for 5–15% discounts and reduced shipping costs via consolidated container loads.

Can suppliers customize print content and format?

Yes, most suppliers support variable data printing including batch numbers, expiry dates, barcodes, QR codes, and custom logos. Software interfaces typically allow font selection, alignment adjustment, and multi-line formatting. Advanced models include USB/SD input or network connectivity for remote job management.

Do suppliers provide global shipping and after-sales support?

Most established suppliers offer worldwide shipping via air or sea freight under FOB or CIF terms. Leading vendors provide English-language manuals, remote troubleshooting, and spare parts supply for at least 12 months post-purchase. Confirm availability of local service agents if operating in Europe, North America, or Southeast Asia.

What are common customization lead times?

Custom firmware, specialized nozzles, or unique mounting configurations require 10–20 days for development and testing. Full system integration with existing conveyor lines may extend timelines to 45 days. Always request prototype validation before mass production begins.