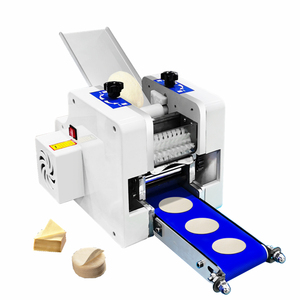

Chapati Making Machine Price In India

About chapati making machine price in india

Where to Find Chapati Making Machine Suppliers?

India’s growing demand for automated food processing equipment has led to a rise in domestic and international suppliers specializing in chapati making machines. While local manufacturing is expanding, a significant portion of high-capacity and semi-automatic systems are sourced from China, where industrial clusters in Guangdong and Henan provinces dominate production. These regions host vertically integrated supply chains that combine sheet metal fabrication, electrical component assembly, and food-grade material sourcing within compact logistics networks.

Manufacturers in these hubs benefit from economies of scale, enabling competitive pricing and rapid prototyping capabilities. Facilities typically integrate CNC punching, roll forming, and robotic welding lines to produce stainless steel pressing units and conveyorized rolling systems. With average factory sizes exceeding 1,000m², suppliers can support both small-batch orders and large-scale deployments for commercial kitchens, hotels, and packaged food producers. Lead times for standard models range from 20–40 days, with air freight options available for urgent procurement needs.

How to Choose Chapati Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical, operational, and transactional criteria:

Technical Specifications & Compliance

Verify machine compatibility with regional voltage standards (220V/110V) and assess compliance with food safety regulations. Look for construction using SUS304 stainless steel for contact surfaces and confirm adherence to IP65 ratings for dust and moisture resistance. While formal certifications such as CE or ISO 9001 are not universally declared, prioritize suppliers who provide test reports on motor efficiency, heating element durability, and dough handling consistency.

Production and Customization Capacity

Evaluate supplier capability through the following indicators:

- Minimum facility size of 1,000m² with dedicated assembly lines

- Offering customization in thickness control (0.8–5mm), output speed (600–2,000 pcs/hour), and mold design for regional flatbread variations

- In-house R&D teams capable of modifying feed mechanisms or integrating gas/electric heating systems

Cross-reference product listings with response time metrics (ideally ≤6 hours) and reorder rates to gauge service reliability.

Procurement Safeguards

Require third-party inspection services prior to shipment, especially for first-time transactions. Utilize secure payment methods with milestone-based releases tied to production progress. Confirm packaging suitability for international shipping, including wooden crate reinforcement and moisture barriers. Request sample units when scaling beyond pilot testing—samples allow performance benchmarking under real kitchen conditions.

What Are the Best Chapati Making Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Verified Focus |

|---|---|---|---|---|---|---|---|---|

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Chapati/Roti Machines, Food Processing Equipment | $850–3,390 | 1 unit | Data not available | ≤6h | Data not available | Limited | Stainless Steel Commercial Units |

| GIRNAR MACHINE PRIVATE LIMITED | Semi-Automatic & Fully Automated Roti Systems | $15–7,358 | 5 pieces | Data not available | ≤25h | Data not available | Moderate | Budget-Friendly Entry Models |

| Guangzhou R&m Machinery Co., Ltd. | Automatic Dough Forming, Papad, Momo, Samosa Lines | $199–8,400 | 1 set | 96% | ≤6h | <15% | Extensive (material, color, size, logo) | Multi-Product Grain Processing |

| In the trend inc. | Chapati, Naan, Thin Pancake Machines | $160–2,600 | 1 set | Data not available | ≤11h | Data not available | Limited | Compact Commercial Units |

| Zhengzhou Inber Machinery Co., Ltd. | Automatic Chapati, Tortilla, Flatbread Makers | $800–1,500 | 1 set | 100% | ≤9h | Data not available | Moderate | Mid-Range Fully Automatic Systems |

Performance Analysis

Among listed suppliers, Zhengzhou Inber Machinery demonstrates strong operational discipline with a verified 100% on-time delivery rate and responsive communication. Guangzhou R&M stands out for customization depth and mid-tier pricing, supported by verifiable annual revenue exceeding US$140,000. LEENOVA offers premium-priced fully automatic systems targeting hotel and catering sectors, while Girnar Machine provides low-cost entry-level models ideal for small bakeries exploring automation. Buyers seeking scalable production should prioritize suppliers with documented after-sales support and spare parts availability.

FAQs

What is the typical price range for chapati making machines in India?

Imported semi-automatic models start at $150–250 per unit for basic configurations, while fully automatic systems with stainless steel construction range from $800 to $3,500. High-output commercial units with integrated proofing and stacking modules may exceed $7,000.

What are common MOQ requirements?

Most suppliers require a minimum order of 1–5 units depending on model complexity. Single-unit orders are accepted for higher-end machines, whereas budget models often mandate bulk purchases to offset shipping and handling costs.

Can chapati machines be customized for Indian flour types?

Yes, reputable manufacturers offer adjustments for dough viscosity, moisture content, and gluten strength typical of atta flour. Custom rollers, feeding trays, and pressure settings ensure consistent texture and roundness across batches.

Do suppliers provide installation and training?

Some suppliers include remote setup guidance via video or manuals. For turnkey installations, request on-site technician deployment at additional cost. Ensure operators receive documentation in English or regional languages for maintenance procedures.

How to verify machine performance before bulk ordering?

Request sample production runs with specified flour ratios and thickness parameters. Conduct live video inspections during testing or engage third-party agencies like SGS for quality audits. Benchmark output against key metrics: shape uniformity, cooking evenness, and hourly throughput.