Cnc Factory As

1/39

1/39

1/18

1/18

1/7

1/7

1/20

1/20

1/16

1/16

1/17

1/17

1/25

1/25

CN

CN

1/23

1/23

1/3

1/3

About cnc factory as

Where to Find CNC Factory AS Suppliers?

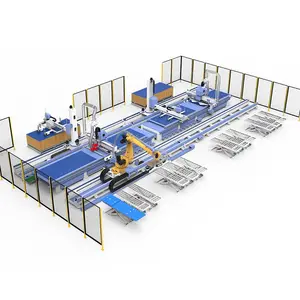

China remains the global epicenter for CNC machinery manufacturing, with Shandong province emerging as a dominant hub for integrated CNC factory solutions. The region hosts a high concentration of vertically integrated suppliers specializing in turnkey production lines for furniture, cabinetry, and wood processing industries. These manufacturers benefit from localized access to steel, electronics, and automation components, enabling cost efficiencies of 20–35% compared to European or North American producers.

Suppliers in Jinan and surrounding industrial zones operate advanced fabrication facilities equipped with robotic welding, precision machining centers, and automated assembly lines. This infrastructure supports scalable production of multi-axis CNC routers, nesting systems, and ATC (Automatic Tool Change) machines. Buyers gain access to mature ecosystems where R&D, prototyping, and volume manufacturing coexist within tight geographic proximity, reducing lead times to 30–45 days for standard configurations. The presence of in-house software development teams further enhances customization capabilities for control systems and workflow integration.

How to Choose CNC Factory AS Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Prioritize suppliers demonstrating full production line ownership, including structural fabrication, electrical integration, and final testing. Key indicators include:

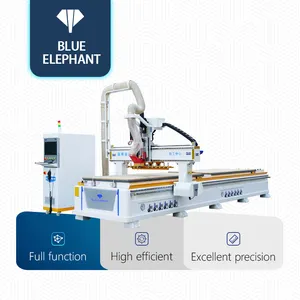

- In-house engineering teams capable of customizing machine size, spindle configuration, vacuum table design, and automation interfaces

- Integration of industrial-grade components such as servo motors, helical racks, linear guides, and NC Studio or DSP control systems

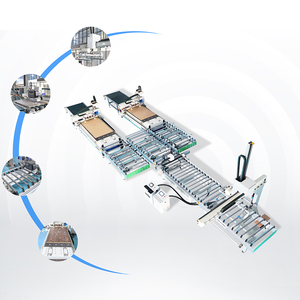

- Capacity to deliver complete processing lines—including labeling, loading/unloading, and dust collection systems—for panel furniture and MDF cabinet manufacturing

Quality Assurance & Operational Metrics

Verify performance through documented metrics:

- On-time delivery rate ≥97% indicates robust production planning and logistics execution

- Response time ≤2 hours reflects dedicated customer support infrastructure

- Reorder rates above 25% signal strong client retention and product reliability

- Minimum online revenue of US $300,000+ suggests consistent market demand and export experience

Transaction Security & Verification

Mitigate risk by requiring third-party validation mechanisms. Favor suppliers offering sample testing prior to full orders. Confirm compatibility with international standards—CE marking is essential for EU market entry, while functional safety assessments apply for automated systems. Utilize secure payment structures such as escrow services to align payment milestones with delivery and commissioning phases.

What Are the Best CNC Factory AS Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization |

|---|---|---|---|---|---|---|---|---|

| Jinan Bcamcnc Machinery Co., Ltd. | Panel Furniture Lines, CNC Routers | $4,999–19,870 | 1 set | 100% | ≤2h | 33% | US $2M+ | Yes |

| Jinan TechPro CNC Equipment Co., Ltd. | ATC Nesting Lines, Cabinet Machines | $30,000–32,000 | 1 set | 100% | ≤1h | 28% | US $620K+ | Yes |

| Jinan Mingshi Machinery Equipment Co., Ltd. | Nesting CNCs, Multi-Head Routers | $2,255–10,580 | 1 set | 100% | ≤1h | 21% | US $300K+ | Yes |

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | High-End ATC, Labor-Saving Systems | $33,000–165,000 | 1 set | 100% | ≤8h | <15% | US $30K+ | No |

| Jinan Pinmai Cnc Equipment Co., Ltd. | Heavy-Duty ATC, Full-Automatic Lines | $7,000–13,500 | 1 set | 75% | ≤4h | 42% | US $20K+ | Yes |

Performance Analysis

Jinan Bcamcnc leads in reorder performance (33%) and revenue scale (US $2M+), indicating strong market acceptance and export maturity. Jinan TechPro and Mingshi stand out for responsiveness (≤1h average reply time) and broad customization options, supporting complex automation integrations such as auto-labeling, multi-head spindles, and oscillating knife systems. While Quick-Fulltek offers premium-priced equipment up to $165,000, its low reorder rate suggests limited repeat business, potentially due to higher pricing or narrower service focus. Pinmai exhibits high customer loyalty (42% reorder rate) despite lower on-time delivery (75%), highlighting potential bottlenecks in logistics or quality control that warrant due diligence.

FAQs

How to verify CNC factory supplier reliability?

Cross-check claimed certifications (e.g., CE, ISO) with official databases. Request facility videos showing active production lines and CNC machining operations. Analyze verifiable transaction metrics such as on-time delivery, response speed, and reorder rates. Evaluate technical documentation for control system compatibility, motor specifications, and structural design details.

What is the typical lead time for CNC machine orders?

Standard units require 25–40 days for production and pre-shipment inspection. Customized or fully automatic lines may extend to 50–60 days depending on complexity. Air freight adds 5–10 days for international delivery, while sea shipping ranges from 20–40 days based on destination port.

Do suppliers offer customization for CNC production lines?

Yes, most established suppliers provide engineering support for tailored worktable sizes, spindle power (air-cooled or water-cooled), vacuum zone configurations, tool magazine capacity, and integration with upstream/downstream automation such as robotic loading or edge banding. CAD/CAM compatibility and 3D simulation are commonly available upon request.

Can CNC machines be shipped globally?

All listed suppliers have export capabilities. Confirm Incoterm preferences (FOB, CIF) and ensure compliance with local electrical standards and safety regulations at the destination. Sea freight is standard for full container loads, while LCL (Less than Container Load) options exist for single-machine shipments.

Is sample testing available before bulk ordering?

Sample units are typically available for key models, though buyers should expect partial cost recovery (30–50%) applied toward the final order. Testing allows verification of cutting accuracy, tool change speed, software interface usability, and noise levels under operational load.