Cnc Machining For Beginners

Top sponsor listing

Top sponsor listing

About cnc machining for beginners

Where to Find CNC Machining for Beginners Suppliers?

China remains the global epicenter for entry-level CNC machining equipment and services, with key manufacturing clusters in Shandong, Guangdong, and Jiangsu provinces. These regions host vertically integrated supply chains that support rapid prototyping, low-volume production, and affordable desktop-scale CNC systems tailored for educational, hobbyist, and small workshop applications. Shandong Province, in particular, has emerged as a hub for beginner-focused CNC routers and milling machines, leveraging localized component sourcing—such as linear guides, stepper motors, and control systems—to reduce final product costs by 20–30% compared to Western alternatives.

The industrial ecosystem enables suppliers to offer complete turnkey solutions—from machine hardware to basic training materials—while maintaining scalability. Proximity to port infrastructure in Qingdao and Dongguan facilitates efficient export logistics, with standard lead times averaging 15–30 days for machine orders and 7–14 days for custom-machined parts. Buyers benefit from a dense network of technical specialists, fabrication workshops, and electronics integrators operating within compact geographic zones, enhancing coordination and reducing development cycles.

How to Choose CNC Machining for Beginners Suppliers?

Selecting reliable suppliers requires due diligence across technical, operational, and transactional dimensions:

Technical Capability Verification

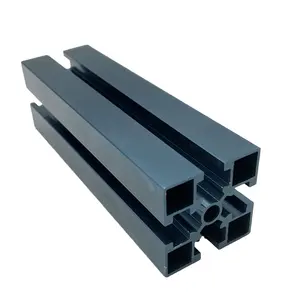

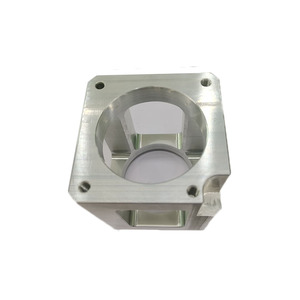

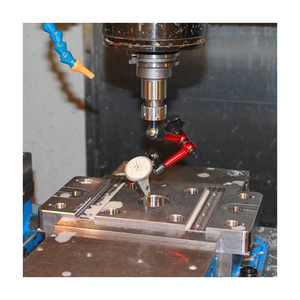

Confirm suppliers offer clear documentation on machine specifications, including spindle power (typically 300W–2.2kW), working area dimensions (e.g., 600x600mm to 1300x2500mm), and compatibility with common CAM software (e.g., UGS, Mach3). For part sourcing, verify supported materials (aluminum, brass, plastics, wood) and precision tolerances (±0.01–0.05mm). Look for evidence of in-house CNC machining centers, CAD/CAM integration, and quality inspection tools such as CMM or micrometer-based checks.

Production & Customization Capacity

Evaluate the supplier’s ability to accommodate customization requests, which may include:

- Material selection (aluminum 6061, brass, ABS, acrylic)

- Surface treatments (anodizing, plating, engraving, laser marking)

- Dimensional adjustments and assembly configurations

- Logo labeling, packaging design, and instructional documentation

Cross-reference stated capabilities with actual product listings and customer reorder rates to assess consistency in delivery and service breadth.

Transaction Reliability Indicators

Prioritize suppliers demonstrating strong performance metrics:

- On-time delivery rate ≥93%

- Average response time ≤7 hours

- Reorder rate above 25%, indicating customer retention

- Transparent pricing structures with MOQs aligned to beginner demand (often 1–50 units)

While formal certifications like ISO 9001 are not always listed, consistent online transaction volume (e.g., $500,000+ annual revenue) and platform-verified order histories serve as proxies for operational maturity.

What Are the Best CNC Machining for Beginners Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|

| Qingdao Dmetal International Trade Co., Ltd. | Machining Services (251), Casting, Sheet Metal | US $1,800,000+ | 100% | ≤7h | 37% | Color, material, size, logo, packaging, graphics | 100 pcs |

| Dongguan Xingchengnuo Metal Products Co., Limited | Precision CNC Parts, Brass/Banjo Components | US $310,000+ | 93% | ≤3h | 23% | Engraving, color, thickness, weight, drawings, logo | 10–50 pcs |

| Lintcnc Tech Co., Ltd. | CNC Routers, Engraving Machines, 4-Axis Systems | US $520,000+ | 94% | ≤3h | 28% | Table size, motor type, control system, tool changer, water tank | 1 set |

| Jinan Style Machinery Co., Ltd. | Wood Routers, Laser Cutters, Plasma CNC Systems | US $740,000+ | 77% | ≤14h | 35% | Limited (machine configuration only) | 1 set |

| Shandong U-May Cnc Technology Co., Ltd. | Desktop CNC Mills, 3-Axis Routers, ATC Systems | US $1,200,000+ | 95% | ≤7h | 58% | User-friendly designs, DIY kits, power options | 1 set |

Performance Analysis

Qingdao Dmetal leads in transaction volume and reliability, with a 100% on-time delivery rate and extensive customization flexibility, making it ideal for buyers seeking machined components in medium batches. Shandong U-May stands out for end-user accessibility, offering beginner-friendly desktop CNC systems at competitive prices ($610–$7,300), backed by the highest reorder rate (58%)—indicative of strong post-purchase satisfaction. Lintcnc and Dongguan Xingchengnuo provide responsive technical support (≤3h response) and robust machine customization, suitable for educators and startups requiring tailored setups. Jinan Style, while offering diverse machinery, lags in responsiveness and delivery consistency, suggesting potential bottlenecks in order processing.

FAQs

What is the typical MOQ for beginner CNC parts or machines?

For machined components, MOQs range from 10 to 100 pieces depending on complexity. Complete CNC machines typically have an MOQ of 1 set, allowing individual buyers and small institutions to procure without bulk commitments.

How long does it take to receive a CNC machine or custom part order?

Standard CNC machine delivery takes 15–25 days after payment. Custom-machined parts ship within 7–14 days, with expedited options available. Add 5–10 days for international air freight or 25–40 days for sea shipping.

Can suppliers provide technical support for first-time users?

Many suppliers offer basic setup guides, video tutorials, and remote troubleshooting. Top-tier vendors like Shandong U-May and Lintcnc include control system documentation and wiring diagrams, though formal training programs are rare without additional fees.

Are samples available before placing a full order?

Yes, most suppliers allow sample orders. For parts, expect to pay full unit cost for quantities under 50. Machine demos are typically virtual; physical samples are not offered due to size and cost.

What customization options are commonly supported?

Suppliers routinely accommodate material substitutions, dimensional tweaks, surface finishes, and branding elements (laser-engraved logos, custom packaging). For CNC machines, upgrades include enhanced spindles, larger worktables, and automatic tool changers (ATC).