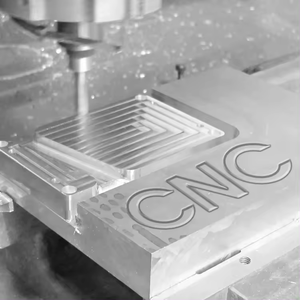

Basics Of Cnc Machining

Top sponsor listing

Top sponsor listing

1/36

1/36

1/18

1/18

1/3

1/3

About basics of cnc machining

Where to Find CNC Machining Suppliers?

China remains a global hub for precision CNC machining services, with concentrated manufacturing clusters in Shenzhen, Dongguan, and surrounding Guangdong Province regions. These areas host vertically integrated facilities specializing in metal and plastic component production, supported by mature ecosystems of material suppliers, tooling experts, and logistics networks. Proximity to Hong Kong and Shenzhen ports enables efficient export operations, reducing shipping lead times by 5–7 days compared to inland regions.

The region’s industrial infrastructure supports both high-volume production and low-volume prototyping, with many suppliers operating multi-axis CNC lathes, milling centers, and automated inspection systems. Buyers benefit from localized supply chains that reduce material costs by 15–25% and enable rapid iteration cycles. Typical advantages include short lead times (7–15 days for prototypes, 20–30 days for bulk orders), scalable production capacity, and extensive customization options across materials such as aluminum, stainless steel, brass, and engineering plastics.

How to Choose CNC Machining Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Equipment

Prioritize suppliers with documented access to 3-, 4-, and 5-axis CNC machining centers, especially for complex geometries. Confirm capabilities in turning, milling, drilling, and surface finishing processes. In-house sheet metal fabrication, casting, and mold-making indicate broader production integration, reducing reliance on third parties and improving quality control.

Quality Assurance Systems

While formal certifications (e.g., ISO 9001) are not universally listed, consistent on-time delivery rates above 95% and verifiable reorder rates suggest stable quality management. Look for evidence of metrology equipment use—such as CMMs or optical comparators—in supplier profiles or product listings. For regulated industries (automotive, medical), request documentation of process validation and material traceability.

Customization and Flexibility

Assess customization depth beyond basic dimensional adjustments. Leading suppliers offer full-service OEM/ODM support, including:

- Material selection guidance (e.g., 6061 vs. 7075 aluminum)

- Surface treatment options (anodizing, plating, passivation)

- Logo engraving, labeling, and packaging design

- Design-for-manufacturability feedback within 24–48 hours

Minimum order quantities (MOQs) range from 1 piece for prototypes to 100+ units for cost-optimized runs. Unit pricing typically starts below $0.50 for simple turned parts and scales based on complexity, tolerances, and finishing requirements.

Operational Responsiveness

Response time is a critical performance indicator. Top-tier suppliers maintain response windows under 2 hours, enabling faster quotation cycles and design iterations. Reorder rates exceeding 30% reflect customer satisfaction and service consistency. Cross-reference online revenue indicators (where available) as proxies for business scale and market demand.

What Are the Best CNC Machining Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Xie Lifeng Technology Co., Ltd. | Machining Services, Sheet Metal Fabrication, Moulds, Casting | 98% | ≤4h | 32% | $930,000+ | Color, material, size, logo, packaging, graphic | 100 pcs | $1.50–$9.90 |

| Chuanghe Fastener Co., Ltd. | CNC Machined Fasteners, Auto Flanges, Spacers, Couplings | 100% | ≤3h | 27% | $220,000+ | Color, material, size, cold heading, logo, designs, label | 100 pcs | $0.50–$1.50 |

| Shenzhen Tuofa Technology Co., Ltd. | Turning Parts, Plastic CNC Components, Milling, Prototyping | 100% | ≤2h | <15% | $150,000+ | Material, size, finish | 1 pc | $0.10–$1.99 |

| Dongguan Xie Lifeng Technology Co., Ltd. | CNC Machining, Moulds, Sheet Metal Fabrication | 90% | ≤4h | 33% | $70,000+ | Material, size, finish | 1 pc | $0.10–$9.90 |

| Aitemoss (America) Intelligent Technology Co., Ltd. | CNC Milling, Rapid Prototyping, Stainless Steel Parts | - | ≤2h | - | - | Material, size, finish | 1 pc | $0.10–$0.57 |

Performance Analysis

Shenzhen Xie Lifeng stands out for high transaction volume and strong reorder metrics, indicating consistent output quality and customer retention. Chuanghe Fastener demonstrates exceptional punctuality (100% on-time delivery) and responsiveness, ideal for time-sensitive automotive or industrial fastener procurement. Shenzhen Tuofa and Dongguan Xie Lifeng offer ultra-low MOQs starting at 1 piece, making them optimal for prototyping and small-batch development projects.

Notably, several suppliers provide sub-dollar unit pricing without sacrificing delivery reliability, reflecting competitive labor efficiency and automation adoption. However, limited certification data necessitates direct verification of quality processes. Buyers should request sample batches and conduct virtual factory audits to assess machine utilization, tool maintenance, and inspection protocols before scaling orders.

FAQs

How to verify CNC machining supplier reliability?

Evaluate on-time delivery history, response speed, and reorder rate as key operational indicators. Request samples to assess dimensional accuracy and surface finish. Conduct video calls to review shop floor organization, machine calibration logs, and quality inspection stations. For long-term partnerships, require proof of material certifications and testing reports.

What is the typical lead time for CNC machined parts?

Prototype orders generally ship within 7–10 days. Production batches (100–1,000 units) take 15–25 days, depending on part complexity and finishing requirements. Expedited processing may reduce timelines by 3–5 days at additional cost.

Can suppliers handle custom material specifications?

Yes, most suppliers accommodate customer-specified materials including 303/304/316 stainless steel, 6061/7075 aluminum, brass, POM (Delrin), PEEK, and nylon. Material sourcing can be client-directed or managed by the supplier with prior approval.

Do CNC machining providers offer design support?

Many offer free DFM (Design for Manufacturing) analysis to optimize part geometry, reduce tooling changes, and minimize waste. Submit STEP or IGES files for quick feedback on manufacturability, tolerance stack-ups, and cost-saving modifications.

What are common surface treatments available?

Standard options include anodizing (Type II/III), zinc/nickel plating, powder coating, passivation, sandblasting, and polishing. Custom textures and laser engraving are also widely supported for branding or functional purposes.