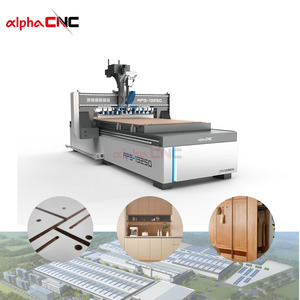

Cnc Router Machining

About cnc router machining

Where to Find CNC Router Machining Suppliers?

China remains the global epicenter for CNC router machining production, with Shandong province emerging as a dominant hub for both entry-level and industrial-grade equipment. The region hosts a dense concentration of manufacturers specializing in woodworking, metal processing, and multi-axis precision systems. Jinan, in particular, has developed a mature ecosystem of vertically integrated suppliers capable of delivering everything from desktop 6040 models to large-format 5-axis gantry routers.

This clustering enables significant cost efficiencies—localized access to cast iron frames, ball screws, servo motors, and control systems reduces material procurement cycles by up to 40%. Facilities often operate within 50km of component suppliers, ensuring rapid assembly and testing. Buyers benefit from scalable production capacity, with standard lead times averaging 25–40 days depending on customization level. Cost advantages range from 20–35% compared to European or North American equivalents, driven by lower labor costs and streamlined logistics networks.

How to Choose CNC Router Machining Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Confirm adherence to international quality standards such as ISO 9001. For export markets, CE marking is essential for regulatory compliance in Europe. Request documentation verifying spindle accuracy (±0.01mm tolerance), repeatability tests, and validation of control systems (e.g., Syntec, DSP A11). Insist on test reports for critical components including linear guides, drive systems, and tool changers.

Production Capability Verification

Assess infrastructure maturity through key indicators:

- Minimum factory footprint of 3,000m² for sustained volume output

- In-house machining and assembly lines (CNC milling, welding, robotic arm integration)

- Dedicated R&D teams supporting custom configurations (ATC, vacuum tables, 5-axis rotation)

- Integration of real-time monitoring tools like CCD cameras and RTCP (Real-Time Control Processing)

Cross-reference supplier claims with verifiable metrics such as on-time delivery rates (>97%) and reorder frequency to assess reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services until final inspection at destination. Prioritize suppliers offering video facility tours and live demonstrations of machine operation. Conduct sample testing to benchmark performance against industry norms—evaluate cutting precision, noise levels (<75dB), and dust aspiration efficiency. Confirm post-sale support availability, including remote diagnostics and spare parts supply chains.

What Are the Best CNC Router Machining Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Jinan Hongda Cnc Equipment Co., Ltd. | CNC Lathe, Wood Routers, EDM Machines | US $990,000+ | 100% | 30% | ≤1h | Limited | $1,300–1,900 |

| Jinan Spower Machinery Technology Co., Ltd. | Industrial CNC Routers, ATC Systems | US $260,000+ | 100% | 58% | ≤1h | Extensive (spindle type, tool changer, safety systems) | $8,999–78,000 |

| Jinan Owin Cnc Equipment Co., Ltd. | Wood Routers, Laser Cutters, Plasma Machines | US $10,000+ | 100% | <15% | ≤2h | Moderate (worktable size, vacuum configuration) | $800–11,000 |

| Jinan Uniontech Machinery Co., Ltd. | 5-Axis Routers, Marble Milling Robots | US $990,000+ | 100% | 18% | ≤2h | High (rotary tables, robotic arms, five-axis integration) | $2,500–49,999 |

| Jinan TechPro CNC Equipment Co., Ltd. | Cabinet Making Machines, Nesting Routers | US $580,000+ | 100% | 25% | ≤1h | Advanced (dust aspiration, auto tool change, 5-axis sculpting) | $3,200–17,000 |

Performance Analysis

Jinan Spower stands out with a 58% reorder rate, indicating strong customer retention driven by extensive customization capabilities and responsive service. Jinan Hongda and TechPro CNC offer competitive pricing for mid-range applications, particularly in woodworking and cabinetry, supported by high online transaction volumes. Uniontech targets niche industrial segments with advanced 5-axis and robotic solutions, though lower reorder rates suggest potential gaps in after-sales engagement. All top-tier suppliers maintain 100% on-time delivery, underscoring operational discipline across the cluster. Buyers seeking automation-ready systems should prioritize suppliers offering ATC, CCD vision alignment, and CAD/CAM compatibility.

FAQs

How to verify CNC router machining supplier reliability?

Validate certifications (ISO, CE) through official registries. Request third-party audit reports detailing quality control procedures, material traceability, and final product testing protocols. Analyze buyer feedback focusing on long-term machine durability, software stability, and technical support responsiveness.

What is the typical sampling timeline for CNC routers?

Standard model samples can be dispatched within 15–25 days. Custom builds involving specialized spindles, tool changers, or control systems require 30–50 days for prototyping and calibration. Air freight adds 7–10 days for international delivery.

Can suppliers handle global shipping and customs clearance?

Yes, established exporters manage end-to-end logistics under FOB, CIF, or DDP terms. Ensure compliance with destination regulations, especially for electrical systems (voltage compatibility) and machinery safety (CE, UL). Sea freight is optimal for full-container loads, reducing transport cost per unit by up to 60%.

Do manufacturers provide free samples or trial units?

Free samples are rare due to high unit value. However, some suppliers offset sample costs against subsequent orders exceeding 2–3 units. Demo units may be available upon request, often requiring a refundable deposit.

How to initiate a customization request for CNC routers?

Submit detailed specifications including working area dimensions, spindle power (6kW–15kW), desired automation features (ATC, conveyor systems), control software preference (Mach3, NC Studio), and material types (wood, aluminum, acrylic). Leading suppliers provide engineering feedback and 3D renderings within 72 hours, followed by prototype production in 3–5 weeks.