Cnc Spindle Producer

1/18

1/18

1/11

1/11

1/25

1/25

1/18

1/18

1/9

1/9

About cnc spindle producer

Where to Find CNC Spindle Producers?

China remains the central hub for CNC spindle manufacturing, with key production clusters concentrated in Dongguan, Changzhou, and Guangdong. These regions host vertically integrated facilities equipped with in-house machining centers, precision assembly lines, and dedicated R&D units focused on high-speed motor technology. Dongguan and Changzhou, in particular, have developed specialized ecosystems for electromechanical components, enabling tight tolerances (±0.005mm) and rapid prototyping cycles.

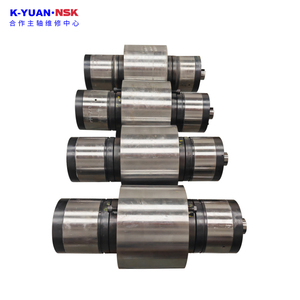

The industrial advantage stems from localized supply chains for critical materials such as high-grade alloy steel, ceramic bearings, and copper windings, reducing component lead times by 20–30%. Facilities typically maintain full production control—from CNC turning and grinding to dynamic balancing and vibration testing—allowing for consistent output of spindles rated between 8,000 and 24,000 rpm. Buyers benefit from scalable production runs, with standard unit lead times averaging 15–25 days and expedited builds available within 7–10 days for urgent orders.

How to Choose CNC Spindle Suppliers?

Effective supplier selection requires verification across three core areas:

Technical Capability Verification

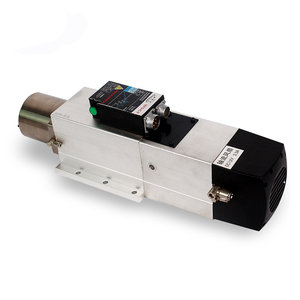

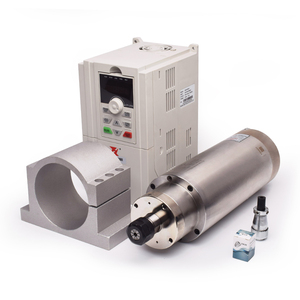

Confirm spindle specifications align with application requirements: power range (800W–9kW), cooling type (air or water), collet compatibility (ER11, ISO30), and rotational speed (up to 24,000rpm). Prioritize suppliers offering test reports for thermal stability, radial runout (<0.003mm), and noise levels (<65dB). For integration into automated systems, verify support for ATC (Automatic Tool Change) and VFD (Variable Frequency Drive) compatibility.

Production Infrastructure Assessment

Evaluate operational scale through measurable indicators:

- Minimum factory area exceeding 2,000m² for stable batch production

- In-house capabilities including CNC machining, motor winding, and final assembly

- Dedicated quality control stations with laser alignment and balance testing equipment

Cross-reference online transaction volumes and on-time delivery rates (target ≥98%) to assess reliability under volume pressure.

Customization & Transaction Security

Assess flexibility for OEM/ODM requests such as custom flange dimensions, color enclosures, labeling, and servo motor integration. Require documentation of packaging protocols to prevent transit damage. Utilize secure payment methods with milestone-based disbursement, particularly for large orders. Pre-shipment inspection (PSI) is recommended to validate performance against agreed technical parameters.

What Are the Leading CNC Spindle Producers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

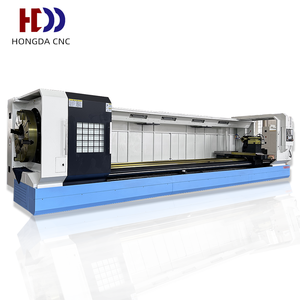

| Dongguan Co-Win Machinery Equipment Co., Ltd. | Dongguan, CN | Multispecialty Supplier | US $410,000+ | 95% | ≤1h | <15% | Full CNC spinning machines (sets) | Limited |

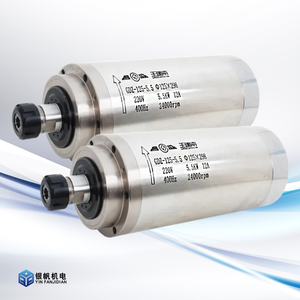

| Changzhou Holry Electric Technology Co., Ltd. | Changzhou, CN | Custom Manufacturer | US $340,000+ | 98% | ≤1h | 29% | Individual spindles (800W–9kW) | Extensive (power, cooling, size, logo, etc.) |

| Changzhou Maples Precision Electromechanical Co., Ltd. | Changzhou, CN | Multispecialty Supplier | US $300,000+ | 100% | ≤3h | 23% | Air-cooled spindles (1.5–4.5kW) | Moderate (color, size, power, packaging) |

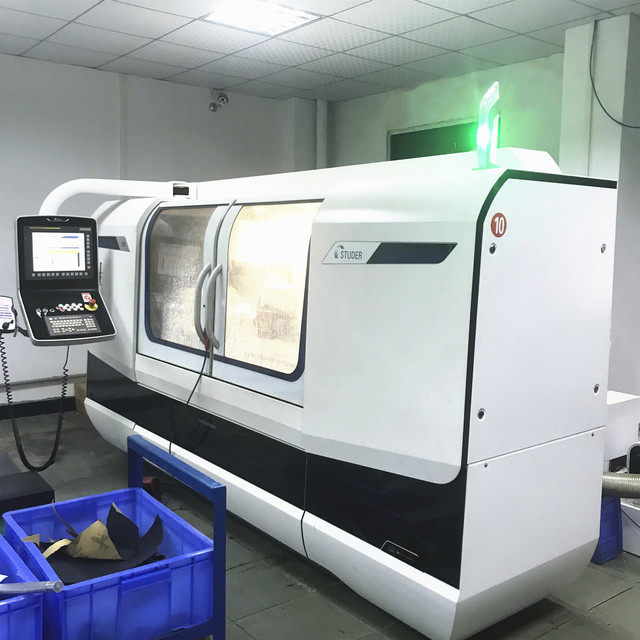

| Xiongyi Intelligent Machinery (Changzhou) Co., Ltd. | Changzhou, CN | Unspecified | US $10,000+ | 100% | ≤2h | <15% | High-end CNC lathes & machining centers | Limited |

| Guangdong Prosper CNC Machine Co., Ltd. | Guangdong, CN | Unspecified | Not disclosed | 100% | ≤7h | Not available | Industrial-scale CNC spinning machines | Limited |

Performance Analysis

Changzhou-based manufacturers dominate in customization depth and responsiveness, with Holry Electric offering over 20 configurable parameters and a 98% on-time delivery rate. Dongguan Co-Win and Guangdong Prosper focus on complete machine solutions priced above $55,000, targeting heavy industrial applications. In contrast, Holry and Maples specialize in modular spindle units with MOQs as low as one piece, making them suitable for integrators and retrofit projects. All top-tier suppliers maintain response times under three hours, though only Holry and Co-Win consistently achieve sub-hour replies. Reorder rates suggest stronger customer retention among custom-focused producers, with Holry’s 29% repeat order rate indicating high satisfaction with tailored solutions.

FAQs

What certifications should CNC spindle producers have?

While not universally listed, reputable suppliers often comply with ISO 9001 standards for quality management. For export to regulated markets, CE marking is essential to demonstrate adherence to electromagnetic compatibility (EMC) and low-voltage directives. Buyers should request compliance documentation for RoHS and REACH where applicable, especially for end-use in European or North American facilities.

What are typical MOQ and pricing ranges?

MOQs vary by supplier type: full-machine producers require 1 set (priced $11,000–$110,000), while component-focused manufacturers offer individual spindles at 1-piece MOQ, ranging from $71.50 (800W air-cooled) to $790 (9kW ATC models). Bulk discounts are commonly available for orders exceeding 10 units.

Can suppliers provide spindle testing data?

Yes, leading manufacturers conduct pre-shipment performance tests including no-load operation (2–4 hours), temperature rise measurement, and vibration analysis. Request video demonstrations or real-time monitoring access for high-value or customized units.

Do CNC spindle producers support global shipping?

All listed suppliers export internationally. Confirm Incoterm preferences (FOB, CIF) and ensure packaging includes wooden crates with anti-vibration padding. Air freight is viable for samples or single units (5–10 days transit), while sea freight is cost-effective for containerized orders (20–35 days).

How long does customization take?

Standard modifications (e.g., labeling, color, flange adjustments) add 3–7 days to production. Full custom designs involving new drawings or motor configurations require 15–25 days, depending on complexity. Prototypes can typically be delivered within three weeks upon approval of technical specifications.