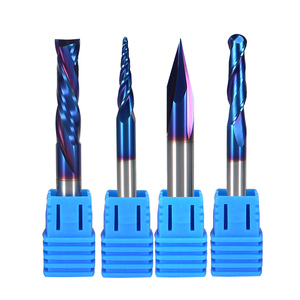

Cnc Tooling

Top sponsor listing

Top sponsor listing

1/17

1/17

0

0

0

0

1/2

1/2

1/22

1/22

1/2

1/2

1/23

1/23

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/21

1/21

0

0

0

0

1/3

1/3

CN

CN

1/3

1/3

0

0

0

0

About cnc tooling

Where to Find CNC Tooling Suppliers?

China remains the global epicenter for CNC tooling production, with specialized manufacturing clusters in Guangdong, Shandong, and Hebei provinces driving competitive advantages. Guangdong—home to Shenzhen and Foshan—hosts advanced precision tooling facilities leveraging high-precision CNC grinding and automated coating technologies. Shandong’s Jinan region focuses on carbide cutting tools and engraving bits, supported by a mature supply chain for tungsten steel substrates. Hebei's suppliers emphasize cost-effective turning tools and lathe accessories, benefiting from proximity to raw material sources and lower labor costs.

These industrial zones enable vertically integrated operations, combining design, sintering, grinding, and coating under one roof. This integration reduces lead times for standard and custom tooling to 15–30 days, while localized component sourcing cuts production costs by 20–35% compared to Western counterparts. Buyers gain access to agile manufacturers capable of fulfilling small-batch prototyping and large-volume orders with consistent quality control and responsive technical support.

How to Choose CNC Tooling Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

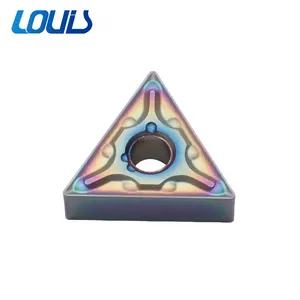

Technical Capabilities & Materials Expertise

Confirm proficiency in key materials such as tungsten carbide, high-speed steel (HSS), and coated alloys (TiN, TiAlN). Suppliers should demonstrate process mastery in CNC grinding, micro-edge preparation, and surface treatments that enhance tool life. For critical applications, verify compatibility with substrates like aluminum, acrylic, stainless steel, or hardened alloys.

Quality Assurance Systems

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not explicitly stated in available data, performance metrics such as on-time delivery (target ≥97%) and low defect rates serve as proxies for process discipline. Cross-reference response times (≤4 hours preferred) and reorder rates (<15% indicates potential satisfaction issues) to assess reliability.

Customization & Engineering Support

Evaluate flexibility in modifying:

- Shank diameter, flute geometry, helix angle, and overall length

- Coating types (e.g., diamond, copper, or ballnose finishes)

- Left-handed or specialized cutting configurations

- Branding options including laser engraving, packaging, and labeling

Suppliers offering OEM/ODM services should provide CAD/CAM file compatibility and rapid prototyping capabilities within 7–14 days.

Production Scalability & Transaction Security

Assess online revenue indicators (e.g., US $100,000+ annual volume) and minimum order quantities (typically 10 pieces for inserts and end mills) as benchmarks for capacity. Use secure payment mechanisms and request sample testing to validate dimensional accuracy, hardness (HRA ≥85), and wear resistance before scaling procurement.

What Are the Best CNC Tooling Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Foshan Shunde Guoqiang Daosheng Industrial Co., Ltd. | CNC Lathe, Milling Machines, Linear Guides, Chuck | 100% | ≤4h | <15% | US $110,000+ | Color, material, size, logo, packaging, graphic |

| Jinan Hard Bar Carving Tools Co., Ltd. | Carbide Engraving Bits, Router Tools, Tungsten Steel Cutters | 99% | ≤2h | 33% | US $270,000+ | Shank size, collet, blade length, handle diameter, coating, packaging |

| Hebei Hebing Technology Co., Ltd. | Turning Tools, Spindle Accessories, Clamps, Pull Claws | 99% | ≤2h | 22% | US $120,000+ | Limited customization noted |

| Shenzhen Stuka Precision Tools Co., Ltd. | Adjustable Centers, Turning Tool Brackets, Thread Rolling Dies | 97% | ≤3h | 20% | US $40,000+ | Application-specific engineering adjustments |

| Shenzhen Metalmate Precision Tools Co., Ltd. | Carbide Inserts, High-Gloss Cutting Tools, Jewelry Tools | 89% | ≤2h | 23% | US $2,000+ | Material, coating, size, application-specific design |

Performance Analysis

Jinan Hard Bar Carving Tools stands out with the highest online revenue (US $270,000+) and strong customer retention (33% reorder rate), indicating robust market demand and service consistency. Foshan Shunde Guoqiang Daosheng achieves perfect on-time delivery (100%), though its low reorder rate suggests room for improvement in post-sale engagement or product differentiation. Hebei Hebing and Shenzhen Stuka offer balanced performance with reliable delivery records (≥97%) and moderate customization depth. Shenzhen Metalmate, despite lower revenue volume, provides niche expertise in coated carbide inserts and mirror-finish aluminum cutting tools, suitable for specialized fabrication workflows.

FAQs

How to verify CNC tooling supplier reliability?

Analyze delivery performance (target ≥97%), response speed (≤4 hours), and reorder behavior. Request evidence of in-house production equipment such as CNC grinders, CMM inspection systems, and coating chambers. Third-party transaction platforms can provide verifiable order histories and dispute resolution records.

What is the typical MOQ and pricing range?

Standard minimum order quantities are 10 pieces for inserts, cutters, and turning tools, with prices ranging from $0.50 to $30 per unit depending on complexity and material. Adjustable precision sets may require single-piece orders at higher price points (up to $317/set).

Do suppliers support custom CNC tool designs?

Yes, most suppliers listed offer OEM/ODM services including custom dimensions, coatings, flute configurations, and branding. Technical specifications should include CAD drawings, tolerance requirements (±0.005mm typical), and application details for optimal matching.

What are common lead times for samples and bulk orders?

Sample production typically takes 7–14 days, with air shipping adding 5–10 days internationally. Bulk order lead times range from 20–35 days depending on customization level and production load. Expedited processing may be available for urgent requests.

Are certifications required for international procurement?

While explicit ISO or CE certifications are not disclosed in supplier tags, compliance with international standards (e.g., DIN, ANSI, or JIS tooling specifications) should be confirmed through technical documentation and sample testing. Buyers in regulated markets should request material test reports and hardness verification.