Cnc Turning Machine Fanuc Control

CN

CN

CN

CN

About cnc turning machine fanuc control

Where to Find CNC Turning Machine Fanuc Control Suppliers?

China remains the global epicenter for CNC turning machine production, with key manufacturing clusters in Shandong and Liaoning provinces driving innovation and scale. Shandong, home to over 70% of China’s mid-sized CNC lathe manufacturers, benefits from a mature ecosystem of component suppliers and precision engineering talent. Dalian in Liaoning province specializes in heavy-duty, high-precision machines, leveraging decades-old industrial infrastructure and proximity to steel and casting facilities that reduce raw material lead times by 20–25%.

These regional hubs support vertically integrated production, enabling suppliers to manage casting, machining, assembly, and control integration in-house. This consolidation results in shorter production cycles—typically 45–60 days for standard Fanuc-controlled lathes—and cost advantages of 15–30% compared to European or North American equivalents. Buyers gain access to flexible MOQs (as low as 1 unit), rapid prototyping capabilities, and customization across spindle configurations, tooling systems, and automation interfaces.

How to Choose CNC Turning Machine Fanuc Control Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

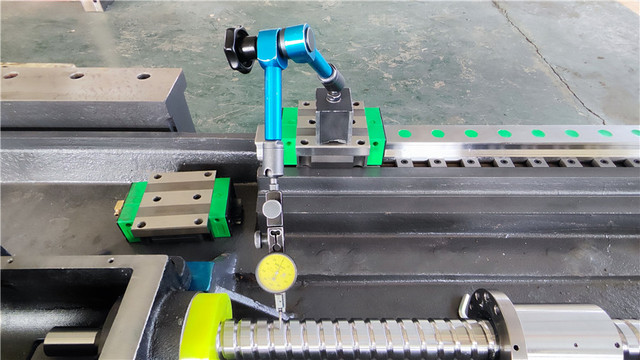

Confirm adherence to ISO 9001 standards as a baseline for quality management. For export markets, CE marking is essential for regulatory compliance. Verify integration of genuine Fanuc controls through documentation and firmware checks. Request test reports on key performance indicators such as positioning accuracy (±0.005mm typical), repeatability, and spindle runout.

Production Capacity Verification

Assess supplier infrastructure using the following criteria:

- Minimum factory area of 3,000m² to ensure stable batch production

- In-house CNC machining and assembly lines to maintain process control

- Dedicated technical teams for customization and post-sale support

Cross-reference online transaction data with on-time delivery rates; prioritize suppliers maintaining 100% fulfillment records.

Procurement Risk Mitigation

Utilize secure payment methods with milestone-based disbursement. Insist on pre-shipment inspection rights and video validation of machine testing under load conditions. Evaluate after-sales service responsiveness—sub-2-hour average reply time indicates strong customer support infrastructure. Sample orders are recommended to assess build quality, control interface stability, and documentation clarity before scaling procurement.

What Are the Best CNC Turning Machine Fanuc Control Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Dalian Jori Co., Ltd. | Liaoning, CN | — | — | — | 100% | ≤2h | US $320,000+ | 40% |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | — | — | — | 100% | ≤3h | US $30,000+ | 100% |

| Dalian Longxing Machinery Equipment Co., Ltd. | Liaoning, CN | — | — | — | 100% | ≤1h | — | — |

| Shandong Yida CNC Machine Tool Co., Ltd. | Shandong, CN | — | — | — | 100% | ≤1h | US $130,000+ | 66% |

| Jinan Kasen Cnc Equipment Co., Ltd. | Shandong, CN | — | — | — | 100% | ≤1h | US $960,000+ | <15% |

Performance Analysis

Suppliers like Dalian Longxing and Shandong Yida demonstrate exceptional responsiveness (≤1h average reply time), indicating robust internal coordination. Jinan Kasen leads in verified sales volume (US $960,000+), reflecting strong market penetration despite a lower reorder rate, suggesting a focus on one-off or project-based clients. Shandong Weste stands out with a 100% reorder rate, signaling high customer satisfaction and product reliability. Dalian-based firms tend to offer higher-end models, with prices exceeding $80,000 for vertical and gantry configurations, while Shandong suppliers provide competitive entry-level options starting below $4,000. Prioritize suppliers offering customization in control system layout, tool magazine integration, and automation readiness for complex manufacturing workflows.

FAQs

How to verify CNC turning machine supplier reliability?

Validate certifications through official registries and request audit trails for quality control processes. Analyze transaction history, focusing on consistent on-time delivery and dispute resolution outcomes. Conduct virtual factory audits to observe assembly practices and testing protocols for Fanuc-controlled units.

What is the typical lead time for CNC lathes with Fanuc control?

Standard models require 45–60 days from order confirmation to shipment. Custom configurations involving multi-axis integration or specialized tooling may extend lead times to 75–90 days. Rush production is available from select suppliers at a 15–25% premium.

Can suppliers customize CNC turning machines with Fanuc control?

Yes, most suppliers offer extensive customization, including spindle speed (6,000–12,000 RPM), motor power, tool holder count, coolant systems, and automation interfaces. Branding options such as color, logo, and packaging labeling are commonly available for OEM partnerships.

What are common MOQ and pricing ranges?

MOQ is typically 1 unit, enabling small-scale procurement. Price ranges vary significantly: entry-level horizontal lathes start at $3,500–$6,000, mid-range slant-bed models range from $15,000–$30,000, while high-precision vertical or 5-axis integrated systems can exceed $180,000 per set.

Do suppliers support global shipping and installation?

Yes, experienced exporters offer FOB and CIF terms with containerized sea freight as the standard method. Some provide optional technician dispatch for onsite commissioning and operator training, particularly for high-value or automated systems.