Compact Cnc Machine

Top sponsor listing

Top sponsor listing

CN

CN

About compact cnc machine

Where to Find Compact CNC Machine Suppliers?

China remains the global epicenter for compact CNC machine manufacturing, with key production clusters in Jiangsu, Shandong, and Anhui provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, cost-efficient component sourcing, and advanced machining capabilities. Jiangsu’s Yancheng and Wuxi zones specialize in high-precision machining centers, supported by mature supply chains for servo systems, spindles, and control units. Shandong's Tengzhou district is recognized for its concentration of CNC lathe and milling machine producers, offering scalable production capacity due to localized foundry and fabrication networks.

The clustering effect enables streamlined logistics and rapid prototyping, with many suppliers operating within 50km of critical subsystem vendors. This proximity reduces lead times for standard models to 30–45 days and supports agile customization cycles. Buyers benefit from competitive pricing—driven by 15–25% lower production costs compared to Western counterparts—and access to manufacturers equipped for both low-volume prototyping and bulk export orders. The region’s focus on automation integration and five-axis technology further enhances value for precision-part producers in aerospace, medical, and electronics sectors.

How to Choose Compact CNC Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm supplier proficiency in core technologies such as multi-axis control (up to 5-axis), high-speed spindle integration (≥8,000 RPM), and compatibility with industry-standard controllers (Fanuc, Siemens, or Syntec). Request documentation on positioning accuracy (typically ±0.005mm–±0.01mm) and repeatability metrics. For customized applications, assess engineering support depth—including CAD/CAM integration, tool path simulation, and fixture design services.

Production Infrastructure Assessment

Evaluate operational scale and process control through the following indicators:

- Facility size exceeding 3,000m² indicating volume production capability

- In-house machining, assembly, and testing lines reducing third-party dependencies

- Dedicated R&D teams supporting firmware updates, automation interfaces, and configuration tuning

Cross-reference these factors with on-time delivery performance (target ≥98%) and digital verification tools such as factory walkthrough videos or real-time production tracking.

Quality & Transaction Assurance

Prioritize suppliers with ISO 9001-certified quality management systems. While not all list CE or RoHS explicitly, compliance should be contractually required for EU/North American shipments. Utilize secure payment mechanisms tied to milestone inspections. Conduct pre-shipment testing on sample units to validate dimensional accuracy, surface finish quality, and long-term thermal stability under continuous operation.

What Are the Best Compact CNC Machine Suppliers?

| Company Name | Main Products (Listings) | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|

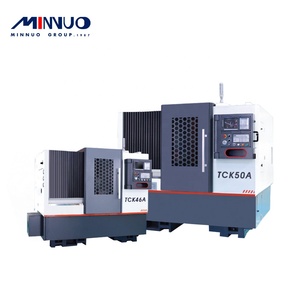

| Jiangsu Minnuo Group Co., Ltd. | Machining Centre (871), CNC Lathe (509) | Color, material, size, logo, packaging, power, 5-axis table | US $6,800,000+ | 100% | ≤2h | 47% |

| Tengzhou Borui CNC Machine Tool Co., Ltd. | CNC Milling Machines, Vertical Machining Centers | Spindle speed, tooling, control system, dimensions, accuracy, language interface | US $860,000+ | 100% | ≤2h | 37% |

| Foshan Sds Smart Tech Co., Ltd. | Mini CNC Lathes, 5-Axis Machining Systems | Double spindle, servo feeder, hydraulic chuck, Swiss-type configuration, programming language | US $410,000+ | 100% | ≤2h | 25% |

| Anhui Sinsun Electronic Commerce Co., Ltd. | CNC Milling Machines (42), CNC Lathe (31) | Limited customization (based on listed product range) | US $10,000+ | 100% | ≤1h | 16% |

| Yiwu Portable Hardware Firm | Portable CNC Plasma Cutters, Laser Cutting Machines | Configuration-based options for portable models | US $180,000+ | 100% | ≤2h | <15% |

Performance Analysis

Jiangsu Minnuo Group stands out with the highest reorder rate (47%) and extensive online revenue, reflecting strong customer retention and broad product coverage across machining centers and lathes. Their deep customization portfolio—including 5-axis rotary tables and power system variants—positions them as a strategic partner for complex, high-mix production environments. Tengzhou Borui demonstrates robust technical flexibility, offering adjustments to spindle parameters, tool setters, and CNC interfaces, making it suitable for buyers requiring precise integration into existing workflows.

Foshan Sds Smart Tech provides access to advanced configurations like Swiss-type lathes and dual-spindle setups, though its lower reorder rate suggests room for improvement in post-sale engagement. Anhui Sinsun offers competitively priced compact mills and lathes with fast response times (≤1h), ideal for time-sensitive procurement, but limited customization scope may constrain scalability. Yiwu Portable Hardware focuses on niche portable CNC cutting systems, serving specialized fabrication needs at entry-level price points.

FAQs

What are typical MOQ and pricing ranges for compact CNC machines?

Minimum order quantities are generally 1 set, with prices ranging from $4,850 for mini CNC mills to over $140,000 for high-precision 5-axis models. Some suppliers accept pallet-level orders for standardized components. Bulk discounts apply above 5 units, particularly for OEM branding or region-specific voltage configurations.

How long do production and shipping take?

Lead times average 30–45 days for standard configurations after deposit confirmation. Customized units may require 50–60 days depending on complexity. Air freight delivers samples within 7–10 days globally; sea freight takes 20–35 days depending on destination port and customs processing.

Can suppliers provide technical drawings and sample units?

Yes, most offer dimensioned CAD drawings and machine specifications upon request. Sample units are available, typically at full cost for single sets. Reimbursement policies vary—some credit sample fees against future bulk orders exceeding 3–5 units.

Do compact CNC machines comply with international standards?

While ISO 9001 adherence is common among leading suppliers, explicit CE or UL certification must be confirmed per unit. Buyers should require test reports for electrical safety, EMI/EMC, and mechanical guarding, especially for deployment in regulated markets.

What customization options are available?

Key configurable parameters include control system type, spindle speed and taper (BT30, BT40), work envelope dimensions, automatic tool changers, coolant systems, and user interface language. Advanced options include synchronized guide bushings, bar feeders, and simulation software integration for turnkey automation cells.