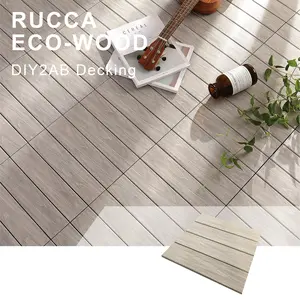

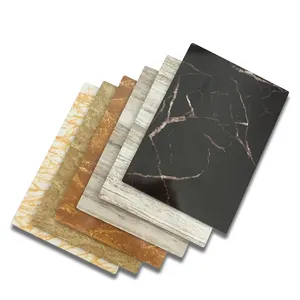

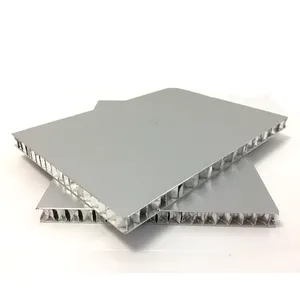

Composite Materials Examples

1/13

1/13

1/12

1/12

1/3

1/3

1/14

1/14

1/19

1/19

1/14

1/14

1/3

1/3

1/3

1/3

1/24

1/24

1/25

1/25

1/31

1/31

1/17

1/17

1/3

1/3

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

About composite materials examples

Where to Source Composite Materials Examples Suppliers?

China leads global production of composite building materials, with key manufacturing clusters in Shandong, Sichuan, and Zhejiang provinces. These regions host vertically integrated facilities specializing in aluminum composite panels (ACP), wood-plastic composites (WPC), and engineered cladding systems. Shandong accounts for over 40% of China’s ACP output, leveraging proximity to steel and polymer feedstock suppliers to reduce material costs by 15–25%. Chengdu and Anji serve as innovation hubs for eco-friendly WPC and alternative plywood composites, supported by regional R&D investments in sustainable construction technologies.

Suppliers in these zones operate high-capacity production lines equipped for continuous lamination, co-extrusion, and PVDF coating processes. The concentration of raw material vendors, processing equipment manufacturers, and logistics networks within 50km radii enables rapid turnaround—standard orders typically fulfill in 15–30 days. Buyers benefit from scalable output, with leading factories reporting monthly capacities exceeding 200,000 square meters. This ecosystem supports both bulk procurement and low-volume customized runs, making it ideal for international distributors and project-based contractors.

How to Evaluate Composite Materials Suppliers?

Adopt the following criteria to assess supplier reliability and technical capability:

Material & Process Standards

Confirm use of industrial-grade polymers (PE, PVDF) and aerospace-grade aluminum alloys (AA3003/AA5005). For exterior applications, PVDF-coated panels must meet ASTM D3763 impact resistance and ISO 2813 gloss retention standards. Request test reports for fire performance (EN 13501-1 B-s1, d0 classification) and accelerated weathering (QUV 1,000+ hours).

Production Infrastructure Assessment

Prioritize suppliers with:

- Minimum 3,000m² manufacturing footprint for consistent batch uniformity

- In-house lamination, CNC cutting, and surface treatment capabilities

- Dedicated quality control labs with spectrophotometers and tensile testers

Cross-reference facility size with online transaction volume—verified annual revenues above US $100,000 indicate operational stability and export readiness.

Order Flexibility & Transaction Security

Analyze minimum order quantities (MOQs) and pricing structures. Competitive suppliers offer tiered pricing starting below $2.00/square meter for volumes over 500 m². MOQs as low as 2 sheets or 2 meters support sampling and small projects. Favor partners with on-time delivery rates exceeding 95%, response times under 2 hours, and participation in third-party payment protection programs to mitigate fulfillment risk.

What Are the Top Composite Materials Suppliers?

| Company Name | Location | Main Products | Customization | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|---|

| Wuxi Tianzhu Special Steel Co., Ltd. | Jiangsu, CN | Aluminum Composite Panels, PVDF-Coated Sheets | Color, size, logo, packaging | 100% | ≤2h | US $320,000+ | 30% | 100 kg / 500 km | $3–15 |

| Anji Pengrui Building Materials Co., Ltd. | Zhejiang, CN | Hollow Decking, Composite Cladding, Wall Panels | Color, material, size, labeling | 96% | ≤1h | US $190,000+ | 22% | 2–200 meters | $1.60–690 |

| Qingdao Ambition Plastic Industry Co., Ltd. | Shandong, CN | Wood-Plastic Composite, Outdoor Decking, Cladding | Color, size | 100% | ≤2h | US $120,000+ | <15% | 2–100 meters | $1.80–15 |

| Chengdu Titanium-Zinc Technology Co., Ltd. | Sichuan, CN | Double-Sided Panels, ACM, Exterior Cladding | Color, size, logo, packaging, graphics | 88% | ≤15h | US $50,000+ | <15% | 50–150 pieces | $4–15.49 |

| Shandong Duoshun Building Materials Technology Co., Ltd. | Shandong, CN | Aluminum Composite Panels, Roof Tiles, Boards | Color, size, sample availability | 100% | ≤1h | US $20,000+ | 18% | 2 sheets | $1.98–12.10 |

Performance Analysis

Wuxi Tianzhu demonstrates strong technical compliance and high reorder volume, indicating customer satisfaction with material consistency. Anji Pengrui stands out for responsiveness (≤1h) and broad customization, suitable for buyers requiring design-specific solutions. Shandong Duoshun and Qingdao Ambition offer the lowest entry MOQs—ideal for prototyping—with 100% on-time delivery records. Chengdu Titanium-Zinc provides competitive pricing but slower response times, suggesting potential communication delays. Prioritize suppliers with sub-2-hour response rates and proven export experience when managing time-sensitive international shipments.

FAQs

How to verify composite materials supplier quality?

Request documentation for material certifications (ISO 9001, CE, RoHS), laminate bond strength tests (≥120 N/mm), and fire ratings. Conduct virtual factory audits to confirm in-line QC procedures and lamination press calibration. Validate claims through transaction histories and buyer feedback focusing on dimensional accuracy and color batch consistency.

What is the typical lead time for composite material orders?

Standard production cycles range from 15 to 25 days after order confirmation. Custom colors or profiles may extend lead times to 35 days. Air freight samples arrive in 7–10 days; sea freight transit takes 20–35 days depending on destination port.

Can suppliers provide free samples?

Yes, most suppliers offer free samples for qualified buyers, particularly when future volume is anticipated. MOQ waivers apply for orders exceeding 500 m². Shipping costs may be charged initially but are often deducted from first purchase invoices.

What customization options are available?

Common customization includes panel thickness (2–6mm), core density, surface finishes (gloss, matte, wood grain), edge profiling, and cut-to-size fabrication. Branding services include logo embossing, custom packaging, and color matching to RAL/Pantone standards.

What are standard packaging and shipping methods?

Panels are palletized with protective film and corner guards; composite decking is bundled with moisture-resistant wrapping. Full container loads (FCL) are cost-effective for orders above 20,000 m². LCL options suit smaller consignments. FOB terms are standard, though CIF can be arranged upon request.