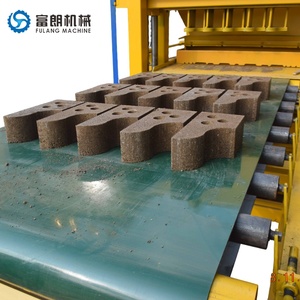

Compressed Block Machine

Top sponsor listing

Top sponsor listing

About compressed block machine

Where to Find Compressed Block Machine Suppliers?

China remains the central hub for compressed block machine manufacturing, with key industrial clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated supply chains that streamline production from raw material sourcing to final assembly. Shandong, in particular, is home to multiple specialized manufacturers leveraging proximity to steel and hydraulic component suppliers, reducing input costs by 15–20% compared to non-industrialized zones. The province's coastal logistics infrastructure supports efficient export operations, enabling faster container loading and reduced shipping delays.

Suppliers in these clusters operate within mature ecosystems where casting, machining, welding, and automation integration occur within compact geographic radii—often under 50km. This proximity enables rapid prototyping and shortens lead times, with standard orders typically fulfilled within 30–45 days. Buyers benefit from scalable production capacity, access to diverse machine types (manual, semi-automatic, fully hydraulic), and flexibility in customization for block dimensions, mold configurations, and power systems. The concentration of technical expertise also facilitates innovation in interlocking brick design and soil stabilization technology.

How to Choose Compressed Block Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical, operational, and transactional criteria:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management systems. For exports to regulated markets, confirm CE marking or equivalent safety certifications. Request documentation for critical components including hydraulic stations, vibration motors, and control panels to ensure durability and compliance with local electrical and mechanical codes.

Production Capability Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 3,000m² indicating capacity for batch production

- In-house engineering teams capable of custom mold design and system integration

- On-site CNC machining, welding, and assembly lines to reduce outsourcing dependencies

Cross-reference declared capabilities with verified performance metrics such as on-time delivery rates (>97%) and reorder frequency to assess reliability.

Customization & After-Sales Support

Confirm availability of configuration options including diesel/electric power sources, hollow/solid block molds, colorant integration, and conveyor integration. Assess responsiveness through average reply time (target ≤2 hours) and language support. Prioritize suppliers offering technical documentation, installation guides, and remote troubleshooting services.

Transaction Security Measures

Utilize secure payment methods with escrow protection until equipment inspection at destination. Review historical transaction data, focusing on dispute resolution records and customer retention rates. Conduct sample testing to validate block density, dimensional accuracy, and cycle time before full-scale procurement.

What Are the Best Compressed Block Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Custom Manufacturer | US $390,000+ | 100% | ≤2h | 66% | Brick Making Machinery, Concrete Batching Plant, Mixers | Block size, color, mold type, hydraulic station, truck integration, logo imprinting |

| Zhengzhou Canmax Machinery & Equipment Co., Ltd. | Henan, CN | Multispecialty Supplier | US $320,000+ | 100% | ≤3h | 27% | Manual/Automatic Earth Presses, Interlocking Brick Machines | Material compatibility, shape, color, packaging, graphic branding |

| Shandong Shunya Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | US $30,000+ | 100% | ≤3h | 25% | Hydraulic Presses, QT4-20/QM2-45 Models, Paving Blocks | Hollow/solid brick types, interlocking molds, mixer integration, power specs |

| Linyi Yingcheng International Trade Co., Ltd. | Shandong, CN | Unspecified | US $240,000+ | 83% | ≤1h | 50% | Clay/Concrete Block Lines, QT2-25 Hydraulic Press | Block shape, thickness, language interface, pallet size, machine layout |

| Shandong Henry Intelligent Machinery Manufacturing Co., Ltd. | Shandong, CN | Custom Manufacturer | US $20,000+ | 100% | ≤4h | 27% | Fully Automatic Hydraulic Presses, Hand Operated Units | Model-specific configurations, interlocking designs, pressure settings |

Performance Analysis

Shandong-based manufacturers dominate the high-reliability segment, with three out of five suppliers achieving 100% on-time delivery. Shandong Hongfa stands out with the highest reorder rate (66%) and extensive customization breadth, making it ideal for buyers requiring integrated systems and branding options. Linyi Yingcheng demonstrates strong customer retention (50% reorder rate) despite lower on-time delivery, suggesting robust post-sale satisfaction. Zhengzhou Canmax offers competitive entry-level pricing ($410–$4,450 range) suitable for small-scale producers, while Shandong Henry provides high-pressure automated solutions targeting commercial output. All top-tier suppliers offer multi-language interfaces and modular designs adaptable to stabilized earth, concrete, and clay-based materials.

FAQs

How to verify compressed block machine supplier reliability?

Cross-check ISO or CE certifications with issuing bodies. Request facility audit reports or video walkthroughs confirming in-house production. Analyze transaction history for consistent delivery performance and review buyer feedback focused on machine uptime and spare parts availability.

What is the typical minimum order quantity (MOQ)?

Most suppliers set MOQ at 1 set per model, allowing low-volume trial purchases. Bulk orders often unlock cost reductions and extended warranty terms. Negotiate bundled packages including molds, conveyors, and mixers for system-wide savings.

What are common customization options available?

Buyers can specify block dimensions (e.g., 400x200x100mm), cavity patterns (solid/hollow), production capacity (QT4 vs QT6 models), power source (electric/diesel), and mold materials. Additional features include automatic ejection, color dosing systems, and logo embossing.

What is the average lead time for production and shipping?

Standard machines are produced within 20–30 days after order confirmation. Custom configurations may require 35–50 days depending on complexity. Sea freight transit adds 15–30 days globally, with FOB terms commonly used for large shipments.

Do suppliers provide technical support and training?

Reputable manufacturers offer operational manuals, setup diagrams, and remote guidance via video call. Some provide on-site technician dispatch (at additional cost) for commissioning and crew training, particularly for fully automated lines.