Custom Built Mfg

CN

CN

Top sponsor listing

Top sponsor listing

1/12

1/12

1/3

1/3

1/22

1/22

CN

CN

1/25

1/25

1/29

1/29

1/20

1/20

1/23

1/23

1/31

1/31

1/29

1/29

1/9

1/9

1/11

1/11

CN

CN

1/17

1/17

1/32

1/32

About custom built mfg

Where to Find Custom Built Manufacturing Service Suppliers?

China remains the global hub for custom-built manufacturing services, with concentrated industrial clusters in Shanghai, Zhejiang, and Guangdong provinces offering integrated production ecosystems. Shanghai and surrounding Yangtze River Delta regions host advanced precision engineering facilities specializing in CNC machining, sheet metal fabrication, and rapid prototyping. Meanwhile, Zhejiang and Dongguan-based suppliers leverage localized supply chains for raw materials and tooling, reducing component lead times by 20–35% compared to offshore alternatives.

These clusters support vertically integrated operations—from design and mold-making to final assembly—enabling end-to-end customization under one roof. Suppliers typically operate dedicated production lines for low-volume, high-mix orders, accommodating client-specific tolerances, materials, and finishing requirements. Buyers benefit from scalable capacity, with average facility sizes exceeding 3,000m² and monthly output adaptable to both prototype development (1–100 units) and medium-batch production (1,000+ units). Proximity to Shenzhen, Ningbo, and Shanghai ports ensures efficient export logistics, with standard air freight delivery within 5–7 days and sea freight options available for bulk shipments.

How to Choose Custom Built Manufacturing Service Suppliers?

Evaluate potential partners using the following criteria to ensure technical capability, quality consistency, and transactional reliability:

Production & Engineering Capabilities

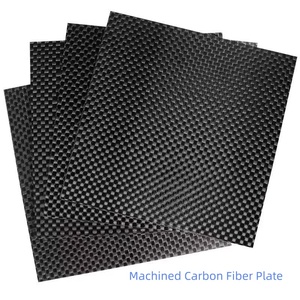

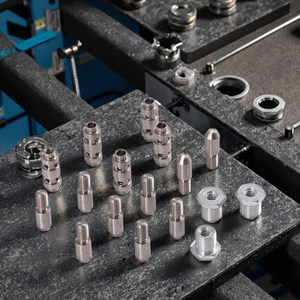

Confirm access to core manufacturing processes including CNC machining, 3D printing, die casting, forging, and sheet metal fabrication. Prioritize suppliers with in-house tooling and mold-making capabilities, which reduce dependency on external vendors and shorten development cycles. Ideal partners maintain R&D teams capable of translating technical drawings into functional prototypes within 7–14 days.

Quality Assurance Systems

While formal certifications (e.g., ISO 9001) are not explicitly listed in available data, consistent on-time delivery rates of 95–100% across multiple suppliers indicate robust internal quality controls. Look for evidence of process standardization through documented inspection protocols, first-article testing, and packaging validation. Suppliers with reorder rates above 40%—such as Zhejiang Yunjiang High Tech Co., Ltd. (46%) and Dongguan Shibo Hardware Products Co., Ltd. (43%)—demonstrate sustained customer satisfaction.

Customization Scope and Flexibility

Top-tier suppliers offer comprehensive customization options, including material selection (aluminum, stainless steel, brass, plastics), surface treatments (anodizing, polishing, oxidation), and branding elements (laser engraving, silk screening, custom labels). Verify that providers accept CAD/CAM files and can accommodate dimensional adjustments, logo integration, and packaging modifications without significant MOQ penalties.

Operational Responsiveness

Response time is a critical performance indicator. Leading suppliers respond to inquiries within 1–2 hours, enabling faster iteration and decision-making. Cross-reference response metrics with order fulfillment history: all five analyzed suppliers report on-time delivery rates at or above 95%, with three achieving 100%. This consistency supports reliable production planning for time-sensitive projects.

What Are the Best Custom Built Manufacturing Service Suppliers?

| Company Name | Verification Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Shanghai Fangyou Precision Machinery Co., Ltd. | Custom Manufacturer | Machining, Sheet Metal, Moulds, Casting, Forging | US $9,000+ | 100% | ≤1h | <15% | Color, Material, Size, Logo, Packaging, Graphics | 1–100 pcs across product lines |

| Zhejiang Yunjiang High Tech Co., Ltd. | Multispecialty Supplier | 3D Printing, CNC Machining, Rapid Prototyping | US $70,000+ | 100% | ≤2h | 46% | Color, Material, Size, Logo, Packaging, Graphics | 1 pc minimum on key items |

| YAOPENG METAL PRODUCTS CO., LIMITED | Custom Manufacturer | CNC Machining, Die Casting, Fast Prototyping | US $40,000+ | 100% | ≤2h | 20% | Silk print, oxidation, heat sinks, die casting, polishing, drawings | 1–100 pcs depending on process |

| Dongguan Shibo Hardware Products Co.,ltd. | Not Specified | Stainless Steel Shafts, Brackets, CNC Parts | US $170,000+ | 95% | ≤3h | 43% | Limited detail; CNC and ODM customization confirmed | 50–500 pcs MOQ range |

| Xiamen Openex Mechanical Technology Limited | Not Specified | Precision Line Parts, Pressure Vessels, Sorting Machines | Not Available | 100% | ≤4h | No Data | Large-scale metal fabrication and structural customization | Ton-based or set-based orders (100 sets+) |

Performance Analysis

Shanghai Fangyou and Zhejiang Yunjiang stand out for responsiveness and customization breadth, with sub-2-hour reply times and extensive aesthetic and dimensional modification capabilities. Zhejiang Yunjiang’s 46% reorder rate reflects strong client retention, likely driven by agile prototyping and competitive pricing ($0.39–12.90/unit across services). YAOPENG METAL offers specialized finishes such as oxidation and silk printing, catering to clients requiring enhanced part durability and branding. Dongguan Shibo commands the highest reported online revenue (US $170,000+), suggesting established export activity and volume throughput despite higher MOQs. Xiamen Openex focuses on large-scale industrial components, serving niche markets requiring heavy fabrication and pressure-rated assemblies, albeit with less transparent commercial metrics.

FAQs

What is the typical MOQ for custom manufacturing services?

Minimum order quantities vary by supplier and process. Many providers, especially those offering 3D printing and CNC machining, accept single-piece orders for prototyping. Batch production typically requires 50–500 units, with metal fabricators often quoting per ton or per set for large components.

How long does it take to receive a custom-manufactured sample?

Standard sample lead time ranges from 7–15 days, depending on complexity. Rapid prototyping via 3D printing or CNC milling can be completed in 3–7 days. Add 5–10 days for international shipping via express carriers. Complex parts involving casting or tooling may require 3–4 weeks.

Do suppliers provide design and engineering support?

Yes, most suppliers offer technical collaboration, including DFM (Design for Manufacturability) feedback, drawing validation, and material recommendations. Providers like Zhejiang Yunjiang and Shanghai Fangyou explicitly promote one-stop design-to-production services, reducing the need for third-party engineering input.

Are there additional costs for customization?

Basic customization (logo, color, size adjustment) is often included within unit pricing. Advanced modifications—such as custom molds, special alloys, or secondary processing (heat treatment, plating)—may incur setup fees or higher per-unit costs. Always request a detailed quote breakdown before approval.

How to verify a supplier's production claims?

Request factory audit reports, video tours of machining floors, and samples of past work. Confirm equipment ownership (e.g., in-house CNC centers) rather than subcontracted production. Use transaction protection programs where available to mitigate risk during initial engagements.