Design Your Own Machine

CN

CN

HK

HK

About design your own machine

Where to Find Design Your Own Machine Suppliers?

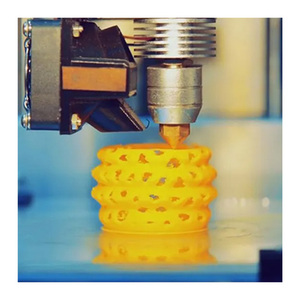

China remains the global epicenter for on-demand machine design and manufacturing, with specialized industrial hubs in Guangdong, Fujian, and Zhejiang provinces leading in precision engineering and rapid prototyping. Dongguan and Shenzhen in Guangdong province host advanced CNC machining and 3D printing ecosystems, enabling high-accuracy component production with turnaround times as low as 7–10 days for prototypes. Fujian’s Xiamen region excels in sheet metal fabrication and laser cutting services, supported by vertically integrated supply chains that reduce material costs by 15–25% compared to Western alternatives.

These clusters offer comprehensive customization infrastructure—from digital design validation to automated assembly—allowing clients to develop fully customized machines based on technical drawings or conceptual sketches. Suppliers leverage localized access to raw materials (aluminum, brass, stainless steel, and engineering plastics) and secondary processing capabilities (anodizing, silk screening, impact-resistant molding) to support full product lifecycle development. Buyers benefit from scalable production models, with MOQs starting at one piece for prototypes and competitive unit pricing at volume tiers (1,000+ units).

How to Choose Design Your Own Machine Suppliers?

Effective supplier selection requires a structured evaluation across three core dimensions:

Design & Engineering Capability

Confirm suppliers possess in-house R&D teams capable of interpreting technical blueprints and offering DFM (Design for Manufacturability) feedback. Priority should be given to partners advertising "customization based on drawings capability" and "on-demand customization ability," indicating proven experience in translating client concepts into functional components. Video facility tours can verify the presence of CAD/CAM software integration and prototype testing labs.

Production & Quality Assurance Infrastructure

Assess operational scale and process control through objective metrics:

- Minimum factory area of 2,000m² for sustained production capacity

- In-house CNC machining, laser cutting, and 3D printing capabilities

- Compliance with ISO 9001 standards for quality management

Cross-reference online revenue data and reorder rates as indicators of market trust—suppliers with reorder rates above 40% typically maintain robust QA systems and responsive communication channels.

Transaction Reliability & Communication Efficiency

Prioritize suppliers demonstrating sub-6-hour response times and 95%+ on-time delivery performance. Short response windows indicate dedicated customer service teams and real-time order tracking systems. Utilize third-party transaction platforms where available to implement milestone-based payments and post-delivery inspections. Request sample units to validate dimensional accuracy, surface finish quality, and material specifications before committing to large-scale orders.

What Are the Best Design Your Own Machine Suppliers?

| Company Name | Location | Main Products | Customization Scope | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | MOQ |

|---|---|---|---|---|---|---|---|---|

| Dongguan Jinchui Precision Hardware Co., Ltd. | Guangdong, CN | Sheet Metal Fabrication, Machining Services | Flexible customization, drawing-based design, ODM/OEM | 100% | ≤6h | 33% | US $6,000+ | 1 piece |

| Xiamen HYM Metal Products Co., Ltd. | Fujian, CN | CNC Machining, Laser Cutting, Wall Decor | Color, size, logo, packaging, material selection | 94% | ≤4h | 52% | US $2,600,000+ | 1–1,000 pieces |

| Hangzhou Yd Sign Co., Ltd. | Zhejiang, CN | 3D Sign Printers, Commercial Printing Equipment | Full system customization for industrial printers | 95% | ≤3h | <15% | US $60,000+ | 1 set |

| SkyReach Intelligent MFG Limited | Guangdong, CN | OEM/ODM CNC Machined Parts | Drawing-based customization, light modification support | 84% | ≤4h | 16% | US $20,000+ | 1 piece |

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | Guangdong, CN | 3D Printing, High-Accuracy Prototypes, Housing Solutions | Anodization, SLA printing, label/graphic integration, material polishing | 100% | ≤2h | 40% | US $900,000+ | 1 piece |

Performance Analysis

Suppliers like Shenzhen Kaier Wo and Xiamen HYM demonstrate strong market validation through high reorder rates (40% and 52%, respectively) and multi-million-dollar annual revenues, reflecting consistent output quality and customer satisfaction. Shenzhen-based firms lead in rapid prototyping agility, with ≤2-hour response times enabling fast iteration cycles. While Hangzhou Yd Sign offers complete machine-level customization (e.g., commercial 3D sign printers), its lower reorder rate suggests potential gaps in post-sale support or niche market alignment. For complex electromechanical systems, prioritize suppliers with documented experience in end-to-end product realization—from initial concept modeling to batch production and packaging customization.

FAQs

How to verify a supplier's customization capability?

Request case studies or project portfolios showcasing previous custom machine builds. Verify technical compatibility by submitting a non-disclosure agreement (NDA)-protected sample drawing and evaluating the supplier’s feedback on manufacturability, tolerances, and material recommendations.

What is the typical lead time for a custom-designed machine?

Prototype development ranges from 7–20 days depending on complexity. Full production cycles for standardized batches (1,000+ units) average 30–45 days after design finalization. Add 7–14 days for international air freight or 25–40 days for sea shipping.

Are there minimum order requirements for custom machines?

MOQs vary: many suppliers accept single-piece orders for prototypes or low-volume testing. Volume production typically begins at 100–1,000 units, with per-unit costs decreasing significantly beyond 5,000 units due to tooling amortization and process optimization.

Do suppliers provide design assistance?

Yes, OEM/ODM-capable manufacturers commonly offer free design consultation, including 3D rendering, structural simulation, and compliance guidance. Some provide SLA or CNC-based rapid prototyping to validate form, fit, and function prior to mass production.

Can I customize branding and packaging?

Most suppliers support full branding integration—including logo imprinting, color matching, custom labels, and retail-ready packaging—especially those advertising “packaging” and “graphic” customization options. Confirm whether additional tooling fees apply for silk screening or mold modifications.