Digikey Capacitor

1/55

1/55

1/27

1/27

1/20

1/20

1/20

1/20

About digikey capacitor

Where to Find Capacitor Suppliers?

China remains a dominant force in global capacitor manufacturing, with specialized production clusters concentrated in Guangdong and Jiangsu provinces. These regions host vertically integrated supply chains that streamline raw material sourcing, precision machining, and final assembly. Shenzhen and Dongguan serve as primary hubs for high-frequency, high-voltage, and solid-state electrolytic capacitors, leveraging proximity to semiconductor fabs and power electronics OEMs. This localization reduces component lead times by 20–35% compared to offshore alternatives.

The industrial ecosystem supports both mass production and niche engineering. Facilities in the Pearl River Delta average 4,000–10,000m² of dedicated cleanroom space, enabling consistent output of SMD and through-hole variants across ceramic, film, tantalum, and supercapacitor technologies. Monthly production capacities range from 500,000 units for standard MLCCs to 50,000 units for custom high-voltage doorknob types. Key advantages include access to domestic barium titanate, aluminum foil, and manganese dioxide supplies, reducing material costs by 15–25% versus Western or Southeast Asian producers.

How to Choose Capacitor Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to IEC 60384 standards for capacitance tolerance, ripple current, and lifetime performance. For industrial or energy applications, validate compliance with RoHS and REACH directives. While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating structured quality management via documented testing protocols—particularly for dielectric strength, ESR, and thermal stability under load.

Production & Engineering Capacity

Assess technical depth through available processing capabilities:

- In-house winding, sintering, and impregnation lines for film and ceramic types

- Custom electrode coating and laser trimming for precision C0G/NP0 variants

- High-voltage testing rigs (up to 60kV) for pulse and DC-link applications

Cross-reference product listings with reorder rates above 20% and on-time delivery exceeding 94% as indicators of operational reliability.

Procurement & Risk Mitigation

Utilize platform-based transaction safeguards such as verified revenue histories and response time benchmarks. Suppliers with sub-2-hour average reply times demonstrate stronger customer engagement. Require sample testing for critical parameters before scaling orders. MOQ flexibility—from single-piece sampling to bulk reels—supports prototyping and volume deployment alike. Negotiate based on tiered pricing structures validated against market benchmarks.

What Are the Best Capacitor Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Foshan Shunde Kesheng Electronics Co., Ltd. | DC-Link, CBB60, High-Voltage | US $340,000+ | 95% | <15% | ≤2h | Yes (color, label, capacity, drawings) | 3–5 pieces | $0.69–13.99 |

| Dongguan Amazing Electronic Co., Ltd. | Ceramic, Doorknob, HV Capacitors | US $10,000+ | 100% | 40% | ≤2h | Limited (custom pF values) | 10–11 pieces | $21–50 |

| Shenzhen Yukun Technology Co., Ltd. | Super Capacitors, Graphene | US $40,000+ | 100% | <15% | ≤1h | No | 10–100 pieces | $0.17–2.50 |

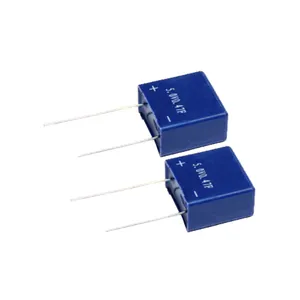

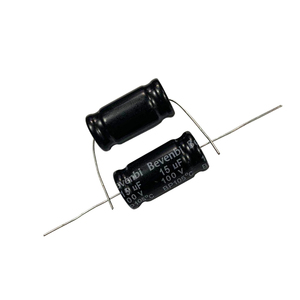

| Digikey Electronic Solutions (Hong Kong) Limited | Solid-State Electrolytic | US $40,000+ | 85% | 21% | ≤2h | No | 1 piece | $0.02–0.86 |

| Shenzhen Worthy Electronics Corp | High-Frequency Ceramic, IGBT Buffer | US $40,000+ | 94% | 16% | ≤4h | No | 1 piece | $0.43–30 |

Performance Analysis

Dongguan Amazing stands out with a 100% on-time delivery rate and 40% reorder frequency, indicating strong customer satisfaction in the high-voltage ceramic segment. Foshan Shunde Kesheng offers the broadest customization scope, including terminal design and labeling, making it ideal for branded or application-specific builds. Shenzhen Yukun excels in ultra-low-cost supercapacitor supply with sub-$0.20 unit pricing at scale. Digikey Electronic Solutions provides the lowest entry barrier with single-unit MOQs and prices starting at $0.02, suitable for rapid prototyping. However, its 85% delivery rate warrants closer shipment monitoring. Shenzhen Worthy targets RF and power conversion niches with kilovolt-rated ceramics but has slower response cycles.

FAQs

How to verify capacitor supplier reliability?

Validate consistency through parametric datasheets and independent lab testing for dissipation factor, insulation resistance, and temperature coefficient. Request batch test reports and inspect packaging integrity. Prioritize suppliers with documented QC processes and verifiable export histories to North America or EU markets.

What is the typical sampling timeline?

Standard capacitor samples ship within 3–7 days. Custom designs (e.g., non-standard doorknob geometries or high-pulse-duty films) require 15–25 days for tooling and validation. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate low-volume orders?

Yes, most listed suppliers support prototype quantities with MOQs as low as one piece. Unit pricing decreases significantly at 100+ and 1,000+ tiers, especially for chip and radial leaded types.

Do manufacturers offer free samples?

Free samples are uncommon for high-value items like 30–60kV capacitors. Some suppliers waive fees for qualified buyers placing follow-up orders. Expect to pay full shipping and handling for hazardous or oversized components.

How to initiate customization requests?

Submit detailed specifications including capacitance value, voltage rating, dielectric type, case size, lead configuration, and operating environment. Suppliers with customization tags can adjust materials, coatings, and markings. Prototypes for modified designs typically take 3–4 weeks after design approval.