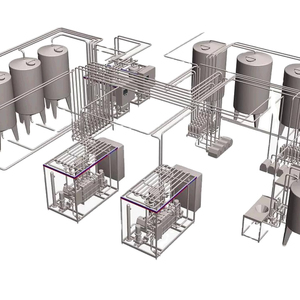

Examples Of Production Process

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About examples of production process

Where to Find Production Line Suppliers?

China remains the global epicenter for industrial production line manufacturing, with key supplier clusters concentrated in Shandong, Shanghai, and Anhui provinces. These regions host vertically integrated facilities specializing in food processing, beverage, dairy, grain, and snack machinery systems. Shandong alone accounts for over 40% of China’s food equipment suppliers, supported by robust metalworking and automation supply chains that reduce component lead times by 20–30%. Proximity to port infrastructure in Qingdao and Shanghai enables efficient containerized shipping for heavy machinery, minimizing logistics delays for international buyers.

The regional ecosystems support both standardized and engineered-to-order production lines, offering scalability from compact turnkey systems to fully automated plants. Suppliers typically operate dedicated assembly lines for blanching, slicing, frying, packaging, sterilization, and filling processes, with modular designs allowing integration into existing facilities. Buyers benefit from localized engineering talent, readily available spare parts networks, and competitive pricing—production lines for instant noodles or potato chips can be sourced at 25–40% lower capital cost compared to European or North American manufacturers.

How to Choose Production Line Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Process Compliance

Verify adherence to recognized quality standards such as ISO 9001 for quality management and CE marking for mechanical safety compliance. For food-grade lines, ensure materials meet FDA or EU 1935/2004 regulations for contact surfaces. Request validation documentation for critical process parameters—including temperature control accuracy, nitrogen flushing efficiency, and deoiling centrifuge performance.

Production Capacity Assessment

Evaluate core infrastructure indicators:

- Minimum factory area of 3,000m² to support full-line assembly

- In-house capabilities covering CNC machining, welding, PLC programming, and hygienic design

- Demonstrated experience with multi-stage processing (e.g., pre-treatment, cooking, cooling, packaging)

Cross-reference online revenue data and on-time delivery rates (target ≥75%) to assess order fulfillment reliability.

Customization & Quality Control

Confirm availability of customization options for output capacity (kg/h), material size, heating method (gas/electric), label configuration, and graphic design. Prioritize suppliers offering video walkthroughs of active production lines and third-party inspection access. Review response time metrics (ideally ≤5 hours) and reorder rates to gauge customer satisfaction and after-sales service effectiveness.

What Are the Best Examples of Production Line Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Zhucheng Lijie Food Machinery Co., Ltd. | Snack Machines, Fryers, Potato Chips Lines | 88% | <15% | ≤2h | US $240,000+ | Blanching, slicing, frying, labeling, gas-heated packaging, flouring, cooling, logo/style | Custom Manufacturer |

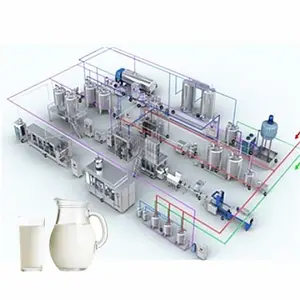

| Shanghai Qingji Beverage Machinery Co., Ltd. | Dairy Processing, UHT, ESL, Soy Milk Lines | 50% | 50% | ≤6h | US $280,000+ | Limited public detail | - |

| Shandong Sunmachine International Co., Ltd. | Instant Noodle, Pizza, Compound Rice Lines | 75% | 27% | ≤5h | US $50,000+ | Output capacity, packaging, peeling, grain processing configurations | - |

| Anhui Jinke Foodstuff Machinery Co., Ltd. | Tortilla, Grain, Baking Lines | 100% | <15% | ≤18h | US $7,000+ | Fully automatic control, power-saving design, user-friendly interface | - |

| Linyi Caisu Machinery Co., Ltd. | Plastic Pipe Extrusion Lines (Used/Second-Hand) | - | - | ≤5h | US $1,000+ | Color, diameter, co-extrusion, foam thickness, SPC flooring profiles | Multispecialty Supplier |

Performance Analysis

Zhucheng Lijie stands out for high responsiveness (≤2h) and strong delivery performance (88%), backed by extensive customization across frying, coating, and packaging stages. Shanghai Qingji commands the highest reported online revenue (US $280,000+) and specializes in high-value dairy and soy milk lines priced between $168,999 and $500,000 per unit, though its 50% on-time delivery rate presents a risk for time-sensitive projects. Anhui Jinke achieves perfect on-time delivery but has slower response times, suggesting potential bottlenecks in customer communication. Shandong Sunmachine offers competitively priced instant noodle lines starting at $8,000/set with solid technical breadth. Linyi Caisu focuses on used plastic extrusion lines, catering to budget-conscious buyers seeking secondary market equipment in good condition.

FAQs

What is the typical MOQ and lead time for production lines?

Minimum Order Quantity is typically 1 set or unit. Lead times vary by complexity: standard food lines require 30–60 days, while custom-engineered systems (e.g., UHT or ESL dairy lines) may take 90–120 days. Used machinery can ship within 15–20 days after inspection.

Do suppliers offer customization for production capacity and layout?

Yes, most suppliers provide configurable output capacities, footprint adjustments, and integration support. Customizations include heating fuel type, nitrogen flushing, automated labeling, and graphic/logo printing. Technical specifications must be submitted in advance for feasibility review.

Are samples or test runs available before purchase?

Full-line sampling is uncommon due to scale, but suppliers often provide video demonstrations, machine trials, or component testing reports. Some offer remote live testing via video call to validate performance parameters.

How are large production lines shipped internationally?

Complete lines are typically shipped via FOB or CIF sea freight in 20' or 40' containers. Buyers should confirm disassembly/packaging protocols, import duties, and destination-side reassembly requirements. Insurance and third-party inspections are recommended prior to shipment.

What payment terms and transaction safeguards are common?

Standard terms include 30% deposit with balance paid before shipment. Escrow services and trade assurance programs mitigate financial risk. Buyers should verify warranty coverage (typically 12 months) and availability of technical support for commissioning.