Examples Of Production And Operations Management

CN

CN

1/3

1/3

1/29

1/29

1/9

1/9

CN

CN

1/8

1/8

1/18

1/18

About examples of production and operations management

Where to Find Product Design and Customization Service Providers?

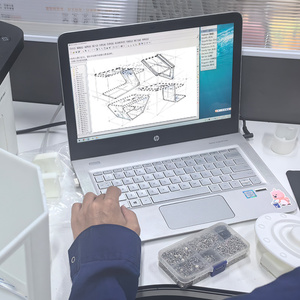

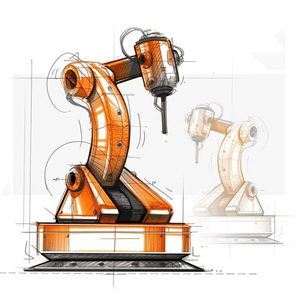

China remains a central hub for product design and engineering services, with specialized clusters in Shenzhen, Dongguan, and surrounding Guangdong regions driving innovation in industrial design, mechanical prototyping, and on-demand manufacturing. These areas host vertically integrated suppliers combining in-house R&D, CNC machining, 3D printing, mold development, and PCB assembly under one operational ecosystem. Proximity to component markets and logistics gateways enables rapid iteration cycles—critical for clients requiring fast turnaround on custom designs.

The region’s mature supply chain infrastructure supports both low-volume prototyping and high-volume production, with many firms operating dedicated ODM/OEM lines. This integration reduces coordination delays between design and fabrication stages, cutting average lead times by 25–40% compared to outsourced models. Suppliers typically offer full-service workflows from concept sketches and CAD modeling to DFM analysis, tooling, and mass production, enabling end-to-end project management. Cost efficiencies stem from localized access to raw materials, skilled labor pools, and precision machinery networks.

How to Choose Product Design and Customization Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Design and Engineering Capability

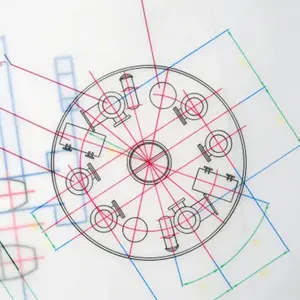

Confirm expertise in key disciplines: industrial design, mechanical engineering, structural development, and PCB/Firmware integration. Suppliers should demonstrate experience across multiple sectors (consumer electronics, industrial equipment, home goods) and provide sample portfolios or client references. Prioritize firms with documented DFM (Design for Manufacturability) reporting and simulation testing protocols.

Production Infrastructure Verification

Assess physical capabilities through verifiable metrics:

- In-house production lines covering machining, molding, and assembly

- Support for light to flexible customization based on drawings or prototypes

- Minimum facility size indicative of scalability (e.g., ≥1,000m²)

- Dedicated technical teams capable of handling iterative revisions

Cross-reference service claims with on-time delivery performance (target ≥95%) and response speed (ideally ≤5 hours).

Quality and Transaction Assurance

While formal certifications (ISO 9001) are not universally listed, prioritize suppliers with structured quality control processes, including prototype validation and assembly drawing verification. Utilize secure payment mechanisms where available and request detailed documentation for material sourcing, tolerance specifications, and packaging standards. Pre-shipment inspections and sample testing remain critical for validating design fidelity before scaling orders.

What Are the Leading Product Design and Customization Suppliers?

| Company Name | Location | Core Services | Customization Level | Min. Order Quantity | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| DONGGUAN TOPWELL TECHNOLOGY CO.,LTD | Dongguan, CN | Industrial design, mechanical & PCB design, mold development, prototyping | Flexible (tooling, materials, color, firmware, packaging) | 1 set | 100.0% | ≤3h | US $770,000+ | 16% |

| Shenzhen Yideyi Technology Co., Ltd. | Shenzhen, CN | CAD design, 3D modeling, PCBA, machining services | Light to flexible (based on drawings) | 1 piece | 100.0% | ≤5h | US $60,000+ | <15% |

| HI-LIGHT INTERNATIONAL INC. | Unspecified, CN | CNC machining, stainless steel tube fabrication, OEM metal parts | Light customization supported | 500–200,000 pieces | 100.0% | ≤7h | Data Unavailable | Not Reported |

| Shenzhen Kuaiji Interactive Technology Co., Ltd. | Shenzhen, CN | Mobile app & e-commerce platform design, software development | On-demand digital customization | 1 set | 100.0% | ≤7h | Data Unavailable | Not Reported |

| CHANNEL TECHNOLOGY LIMITED | Unspecified, CN | Product engineering, 3D modeling, mechanical design | Light customization with prototype support | 1 set | 66.0% | ≤4h | US $3,000+ | <15% |

Performance Analysis

DONGGUAN TOPWELL stands out with comprehensive customization options, high online transaction volume, and perfect on-time delivery, indicating robust internal coordination. Shenzhen-based firms like Yideyi and Kuaiji specialize in digital and hardware-integrated solutions, offering low MOQs ideal for startups and SMEs. HI-LIGHT INTERNATIONAL targets higher-volume industrial clients with CNC and metal fabrication services, though customization depth is more limited. CHANNEL TECHNOLOGY shows responsiveness advantages but lower fulfillment reliability (66% on-time rate), suggesting potential bottlenecks in production scheduling. Buyers seeking full-spectrum design-to-manufacturing support should prioritize suppliers with proven track records in both mechanical and electronic system integration.

FAQs

What level of customization can these suppliers support?

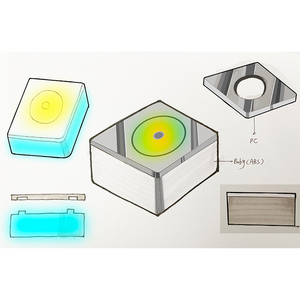

Most offer light to flexible customization, including modifications to size, material, color, logo, packaging, and functional components such as firmware or PCB layout. Some support full design-from-scratch projects using client sketches or technical drawings.

What are typical minimum order quantities?

MOQs vary by product type: digital and design-only services often require just 1 unit/set, while machined or molded parts range from 500 to 3,000+ units. High-volume metal components may require 200,000 pieces for cost-effective runs.

How long does it take to receive a prototype?

Prototype development typically takes 7–21 days depending on complexity. Additional time is required for tooling if injection molding or die casting is involved. Suppliers usually provide CAD renderings within 72 hours of inquiry.

Do suppliers accept design-only projects without production?

Yes, several providers offer standalone design services—including 2D/3D CAD, industrial styling, and DFM reports—without requiring subsequent manufacturing commitments.

Are there additional costs for customization?

Base pricing often includes standard customization. Significant deviations (e.g., new molds, proprietary materials) incur extra charges. Tooling and setup fees are typically quoted separately for first-time productions.