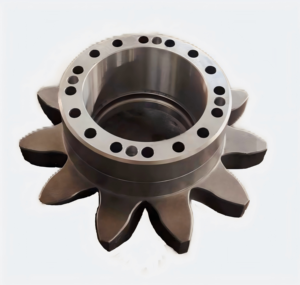

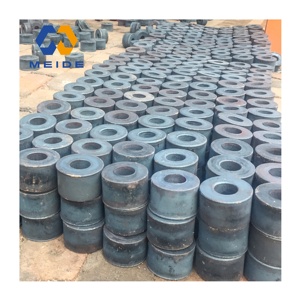

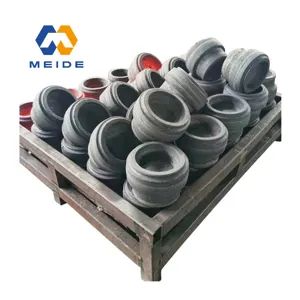

Forging Products Examples

Top sponsor listing

Top sponsor listing

1/24

1/24

1/22

1/22

CN

CN

1/22

1/22

CN

CN

1/27

1/27

1/36

1/36

1/40

1/40

1/9

1/9

1/12

1/12

CN

CN

1/33

1/33

1/33

1/33

CN

CN

1/10

1/10

1/11

1/11

About forging products examples

Where to Find Forging Products Suppliers?

China remains a dominant force in the global forging industry, with key manufacturing clusters located in Zhejiang, Shandong, and Guangdong provinces. These regions host vertically integrated facilities specializing in hot, cold, and precision forging techniques for carbon steel, stainless steel, aluminum, and high-alloy materials. The concentration of metallurgical expertise, access to raw material supply chains, and mature fabrication ecosystems enable competitive production costs—typically 20–35% lower than Western counterparts—while maintaining compliance with international mechanical property standards.

Suppliers in Ningbo and Qingdao have developed specialized capabilities in custom OEM/ODM forging services, supported by co-located CNC machining, casting, and surface treatment operations. This integration reduces lead times for finished components to 15–30 days on average. Industrial zones in these cities offer logistical advantages, including proximity to major ports and certified testing laboratories, facilitating faster export processing and quality validation for North American and EU markets.

How to Choose Forging Products Suppliers?

Selecting reliable forging suppliers requires a structured evaluation across technical, operational, and transactional criteria:

Material & Process Expertise

Confirm supplier proficiency in required forging methods—hot forging for large structural components, cold forging for high-tolerance fasteners, and precision forging for aerospace or automotive applications. Verify capability in specified alloys, including common grades such as 40Cr, 42CrMo, S355J2, and AL6061-T6. Request process flow documentation covering billet heating, die design, post-forging heat treatment, and dimensional inspection.

Quality Assurance Systems

Prioritize suppliers with ISO 9001 certification and documented quality control protocols. While not all suppliers list formal certifications in public data, consistent on-time delivery (target ≥98%) and traceable inspection records are strong proxies for reliability. Demand test reports for tensile strength, hardness (HB/HRC), and non-destructive testing (NDT) where applicable, especially for load-bearing parts.

Customization & Minimum Order Requirements

Evaluate flexibility in customization parameters: material grade, geometric tolerances, surface finish (e.g., black oxide, anodizing), and branding options (laser marking, packaging). MOQs vary significantly—from 1 piece for prototype runs to 1,000 pieces for cost-optimized batches. Suppliers offering low or no MOQs often cater to R&D or niche industrial clients but may require higher per-unit pricing.

Production Capacity & Responsiveness

Assess scalability through facility size indicators and online revenue estimates. Suppliers with annual digital transaction volumes exceeding US $500,000 typically maintain dedicated production lines and engineering support teams. Response time under 4 hours and reorder rates above 30% indicate strong customer satisfaction and operational stability.

What Are the Best Forging Products Suppliers?

| Company Name | Main Materials | Key Services | MOQ Range | Unit Price Range | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Ningbo Inunion Import And Export Co., Ltd. | Carbon Steel, Stainless Steel, Aluminum, High-Alloy | Precision Hot Forging, Cold Forging, CNC Machining, OEM | 1–10 pieces | $0.05–$12.00 | 100% | ≤1h | 31% | US $900,000+ |

| Qingdao Hulk Metal Technology Co., Ltd. | Carbon Steel, Alloy Steel | Hot Forging, Custom Mold Design, OEM Services | 1,000 pieces | $0.15–$10.40 | 100% | ≤4h | <15% | US $60,000+ |

| Jiyuan Haiyuan Special Steel Co., Ltd. | 40CrNiMo, 42CrMo, GH4169, 40Cr | Heavy-Duty Forging, Large Gear Production, CNC Integration | 1 piece | $25–$1,350 | 100% | ≤1h | - | - |

| Qingdao Weser Trading Co., Ltd. | SS304, AL6061-T6, S355J2 | Forged Hubs, Hydraulic Components, Machined Aluminum Parts | 10–1,000 kg | $2.50–$8.00/kg | 100% | ≤4h | - | - |

| Zhongshan Meichen Hardware Products Factory | Motorcycle Components, General Hardware | Forging, Machining, Casting, Fabrication | Data Unavailable | Data Unavailable | 100% | ≤3h | 100% | US $20,000+ |

Performance Analysis

Ningbo Inunion stands out for low-volume flexibility and rapid response, supporting prototyping and small-batch production with MOQs as low as one piece and broad material versatility. Its 31% reorder rate and sub-hour response time reflect strong service execution. Qingdao Hulk offers competitive pricing for volume orders but has a lower reorder rate, suggesting potential gaps in long-term client retention despite reliable delivery. Jiyuan Haiyuan specializes in high-value, mission-critical forgings—including super-large gears and aerospace-grade alloys—with full customization at single-piece MOQs, indicating advanced tooling and engineering capacity. Qingdao Weser focuses on weight-based pricing for forged aluminum and steel components, catering to buyers needing bulk material procurement. Zhongshan Meichen demonstrates perfect reorder performance, likely due to niche focus on motorcycle system parts and integrated fabrication services.

FAQs

What materials are commonly used in forging products?

Common materials include carbon steel (e.g., 45#, 40Cr), alloy steels (42CrMo, 30CrNiMo), stainless steels (304, 316), and aluminum alloys (6061-T6, 7075). Material selection depends on required strength, corrosion resistance, and operating temperature.

What is the typical lead time for forged components?

Standard orders take 15–25 days from confirmation, depending on complexity and finishing requirements. Prototype samples can be delivered in 7–14 days for simple geometries, while custom tooling may add 10–20 days.

Do forging suppliers provide design and engineering support?

Yes, many suppliers offer free 3D modeling, die design, and DFM (Design for Manufacturability) analysis. Companies like Ningbo Inunion and Jiyuan Haiyuan explicitly list graphic and CAD customization options, enabling iterative development with clients.

Can I request samples before placing a bulk order?

Most suppliers allow sample production, often at reduced or waived cost if followed by a confirmed order. Single-piece MOQs effectively serve as sampling options, particularly for high-unit-value items like large gear forgings or aerospace components.

What surface treatments are available for forged parts?

Available treatments include black oxide, phosphating, zinc plating, anodizing (for aluminum), and shot peening. Some suppliers also offer painting, powder coating, or laser engraving for identification and corrosion protection.