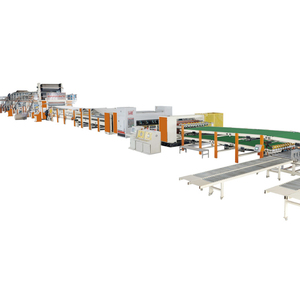

Fully Automatic Corrugated Box Making Machine China

CN

CN

About fully automatic corrugated box making machine china

Where to Find Fully Automatic Corrugated Box Making Machine Suppliers in China?

China is the leading global producer of fully automatic corrugated box making machines, with key manufacturing clusters concentrated in Hebei and Cangzhou regions. These industrial hubs host vertically integrated facilities that specialize in end-to-end packaging machinery production—from single-facer units to complete corrugated cardboard production lines. The concentration of component suppliers, skilled labor, and logistics infrastructure enables efficient scaling for both standard and customized orders.

Suppliers in this ecosystem benefit from localized supply chains for critical materials such as steel frames, PLC control systems, rubber rollers, and precision cutting tools. This integration reduces lead times and production costs by 20–30% compared to non-specialized markets. Buyers gain access to scalable solutions ranging from compact semi-automatic models to high-speed, multi-layer (3/5/7-ply) fully automatic systems capable of processing up to 200 meters per minute. Average delivery windows range from 30 to 60 days depending on customization level and order volume.

How to Choose Fully Automatic Corrugated Box Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

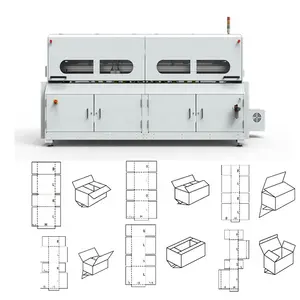

Confirm machine specifications align with intended output requirements, including ply capacity (3/5/7 layers), maximum speed (m/min), and compatibility with flexo printing, slotting, die-cutting, and creasing modules. Demand documentation on core components—such as Siemens or Mitsubishi PLC controls, frequency inverters, and pneumatic systems—and verify compliance with international safety standards like CE where applicable.

Production Capacity Assessment

Evaluate supplier infrastructure based on:

- Proven track record in manufacturing full-line corrugated box systems

- In-house engineering teams supporting customization (e.g., size, voltage, automation level)

- Capacity for end-to-end assembly and testing prior to shipment

Cross-reference online revenue indicators and reorder rates to assess market confidence. Prioritize suppliers with verified on-time delivery performance exceeding 98%.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only after equipment verification. Request pre-shipment inspection reports or video walkthroughs of assembled machines. For large investments, consider engaging third-party auditors to validate factory operations and quality management systems. Always request sample production runs or prototype validation when implementing custom configurations.

What Are the Leading Fully Automatic Corrugated Box Making Machine Suppliers in China?

| Company Name | Type | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Online Revenue |

|---|---|---|---|---|---|---|---|

| Hebei Lincheng Packaging Machinery Manufacturing Co., Ltd. | Custom Manufacturer | $30,000–650,000 | 100% | ≤5h | - | Color, material size, logo, packaging, label, graphic | Not disclosed |

| AOPACK Ltd. | Multispecialty Supplier | $50,000–150,000 | 100% | ≤4h | - | Not specified | US $40,000+ |

| Cangzhou Kingsun Imp. & Exp. Co., Ltd. | Multispecialty Supplier | $4,500–138,000 | 100% | ≤2h | 42% | Color, feeder, folding, packaging, roller, adjust settings, material size, logo | US $1,300,000+ |

| Cangzhou Lighten Import & Export Trading Co., Ltd. | Multispecialty Supplier | $20,000–200,000 | 100% | ≤3h | 66% | Die cutting, color, material size, length, logo, packaging, label, graphic | US $120,000+ |

| Cangzhou Jialong Packaging Machinery Co., Ltd. | Multispecialty Supplier | $11,000–200,000 | 100% | ≤3h | 50% | Logo, packaging, label | US $1,000,000+ |

Performance Analysis

Hebei Lincheng offers the widest price and capability range, including high-end systems priced up to $650,000, indicating specialization in premium automated lines. Cangzhou-based suppliers dominate responsiveness, with three providers achieving average reply times under 3 hours—critical for iterative technical discussions. Cangzhou Lighten leads in customer retention with a 66% reorder rate, suggesting strong post-sale support and product reliability. A notable trend is broad customization availability across all suppliers, covering functional adjustments (creasing wheels, feeder types) and branding elements (color schemes, labels). Suppliers with higher online revenues (>US $1M) demonstrate consistent export experience and scalability for bulk procurement.

FAQs

What certifications should I expect from reputable suppliers?

While ISO 9001 is not universally listed, many suppliers comply with CE standards for electrical and mechanical safety. Buyers should explicitly request certification documents and test reports for PLC systems, motors, and structural components. Third-party verification enhances due diligence, especially for regulated markets in Europe and North America.

What is the typical minimum order quantity (MOQ)?

The standard MOQ across all listed suppliers is 1 set, facilitating pilot procurement and small-scale deployment. This low entry threshold supports buyers evaluating machine performance before committing to full production line installations.

How long does it take to receive a machine after ordering?

Lead time typically ranges from 30 to 60 days, depending on complexity and customization. Standard configurations ship faster, while integrated lines with printing, slotting, and die-cutting modules may require additional assembly and testing time.

Can these machines be customized for specific box sizes or production speeds?

Yes, all five suppliers offer customization options for material size, folding patterns, voltage (220V/380V), and control interfaces. Advanced modifications—including variable speed drives, extended conveyor systems, and integration with upstream/downstream equipment—are supported by suppliers with dedicated R&D capabilities.

Do suppliers provide installation and training support?

Most suppliers offer remote guidance via video or manuals. On-site installation and operator training can often be arranged at additional cost. Confirm service terms during negotiation, particularly for complex systems requiring precise calibration.