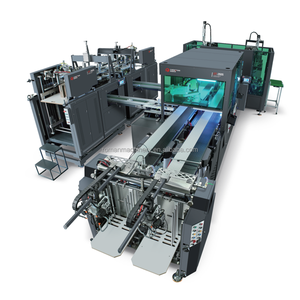

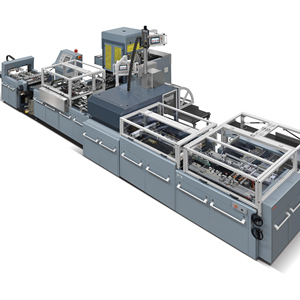

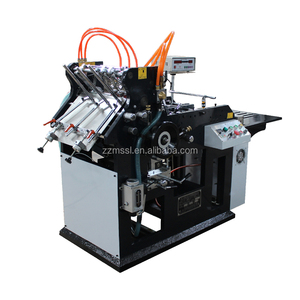

Fully Automatic Sweet Box Making Machine

1/6

1/6

1/9

1/9

1/16

1/16

1/16

1/16

1/14

1/14

1/12

1/12

1/11

1/11

1/16

1/16

1/26

1/26

About fully automatic sweet box making machine

Where to Find Fully Automatic Sweet Box Making Machine Suppliers?

China remains the global epicenter for automated packaging machinery production, with key manufacturing clusters in Zhejiang, Guangdong, and Henan provinces driving innovation and cost efficiency in the fully automatic sweet box making machine sector. Wenzhou and Dongguan serve as primary hubs for precision paper box automation equipment, hosting vertically integrated suppliers capable of delivering turnkey solutions. Henan, particularly Zhengzhou, has emerged as a competitive center for mid-range industrial automation systems, offering 20–35% lower unit costs due to regional economies of scale and optimized supply chains for servo motors, pneumatic components, and die-cutting modules.

These industrial zones support rapid prototyping and scalable production through co-located material processing, CNC machining, and assembly facilities within 50-kilometer ecosystems. Suppliers in these regions typically maintain lead times of 25–40 days for standard configurations, with access to certified component vendors enabling consistent compliance with international electrical and mechanical safety standards. The concentration of engineering talent and logistics infrastructure allows for efficient air and sea freight coordination, supporting global export operations to Europe, North America, and Southeast Asia.

How to Choose Fully Automatic Sweet Box Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical compatibility, operational reliability, and transaction security.

Technical Compliance & Certifications

Verify adherence to ISO 9001 quality management systems as a baseline requirement. For markets requiring regulatory alignment, confirm CE marking for electrical control panels and compliance with IEC 60204-1 safety standards. Request documentation on core system components—such as PLCs (Siemens or Mitsubishi), servo drives, and HMI interfaces—to assess durability and serviceability. Machines designed for food-grade packaging must utilize stainless steel contact surfaces and meet hygiene design principles per EHEDG guidelines.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area exceeding 3,000m² to support dedicated R&D and testing lines

- In-house engineering teams specializing in motion control, folding mechanics, and gluing systems

- Integrated CNC and laser cutting capabilities for mold and die plate fabrication

Cross-reference online revenue metrics and order fulfillment rates: suppliers with verified annual revenues above US $500,000 and on-time delivery performance ≥98% demonstrate proven scalability and operational stability.

Customization & Transaction Security

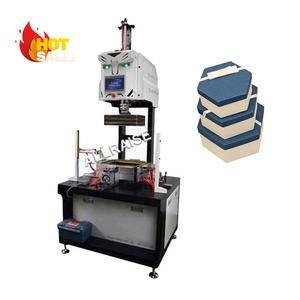

Confirm availability of customization options including box dimensions (standard range: 50–200mm width), material thickness (0.8–3.0mm rigid board), and integration of hot stamping, embossing, or flexographic printing units. Require detailed CAD drawings and functional prototypes prior to full commitment. Utilize secure payment mechanisms such as escrow services with milestone-based release terms. Prioritize suppliers offering sample testing under real production conditions, with clear return policies for non-conforming units.

What Are the Best Fully Automatic Sweet Box Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | US $1.3M+ | 100% | ≤1h | <15% | 5 models | Color, size, logo, packaging, graphic | $6,000/set |

| Dongguan Pinchuang Automation Equipment Co., Ltd. | Guangdong, CN | US $730K+ | 100% | ≤1h | – | 5 models | Limited public data | $23,000/set |

| ZHENGZHOU ALLRAISE COMPANY LTD. | Henan, CN | US $960K+ | 98% | ≤3h | 38% | 5 models | Color, size, logo, packaging, graphic | $6,856.52/set |

| Zhengzhou Perfect Co., Ltd. | Henan, CN | US $80K+ | 100% | ≤3h | <15% | 5 models | Extensive (design, material, printing, automation) | $12,500/set |

| Henan Gyang Machinery Co., Ltd. | Henan, CN | US $110K+ | 100% | ≤3h | <15% | 5 models | Limited to desktop/small business variants | $4,540/set |

Performance Analysis

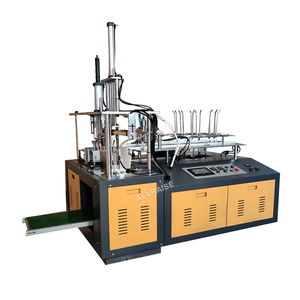

Wenzhou Roman Machinery leads in responsiveness and transaction volume, combining sub-one-hour response times with a broad product portfolio and strong export performance. Dongguan Pinchuang targets high-end applications, with machine prices reaching $103,371, indicating specialization in complex, multi-functional forming systems. ZHENGZHOU ALLRAISE distinguishes itself with a 38% reorder rate—the highest among listed suppliers—suggesting strong customer satisfaction despite slightly longer response cycles. Zhengzhou Perfect offers the most comprehensive customization capabilities, supporting advanced features like flexo printing and bagasse-based material processing. Henan Gyang provides entry-level desktop solutions starting below $5,000, catering to small-scale confectionery producers seeking low MOQs and compact footprints.

FAQs

What is the typical minimum order quantity (MOQ) for fully automatic sweet box making machines?

All listed suppliers offer single-set orders (MOQ: 1 set), facilitating pilot procurement and small business adoption. Bulk pricing applies at 2+ units, with discounts varying by model complexity and customization level.

What are common lead times after order confirmation?

Standard delivery windows range from 25 to 40 days post-deposit, depending on machine configuration. Customized systems with integrated printing or robotic loading may extend lead times to 50–60 days. Expedited builds are available at additional cost, reducing timelines by 7–14 days.

Do suppliers support OEM/ODM services?

Yes, most suppliers listed provide OEM labeling and ODM redesign services. Capabilities include custom UI languages, brand-specific color schemes, and proprietary mechanical adjustments. Engineering collaboration is typically required for structural modifications affecting folding accuracy or glue application dynamics.

Are spare parts and technical support included?

Standard packages include basic toolkits and one-year warranty coverage for critical components (PLC, motor drivers, sensors). Extended service agreements and spare parts kits (e.g., cutting blades, gripper belts, nozzles) are available upon request. Remote diagnostics via HMI connectivity are commonly supported; on-site technician dispatch may incur additional fees outside China.

How to evaluate machine compatibility with specific box designs?

Submit detailed technical specifications including blank template dimensions, crease patterns, adhesive type (cold glue, hot melt), and target output speed (typically 30–80 boxes/minute). Reputable suppliers will conduct feasibility analysis and provide simulation videos or physical samples using client-provided materials before finalizing contracts.