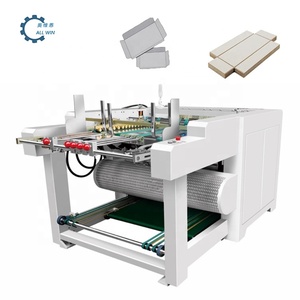

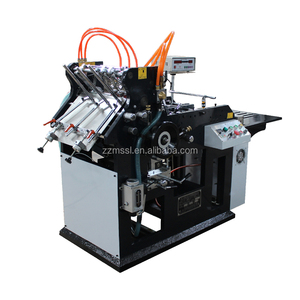

Automatic Sweet Box Making Machine

About automatic sweet box making machine

Where to Find Automatic Sweet Box Making Machine Suppliers?

China remains the global epicenter for automatic sweet box making machine manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Henan provinces. These regions host vertically integrated supply chains that support rapid prototyping and high-volume production of packaging automation equipment. Guangdong’s Pearl River Delta region excels in intelligent machinery development, leveraging proximity to electronics and control system suppliers to enhance machine precision and programmability. Henan and Zhejiang focus on cost-efficient engineering, offering competitive pricing due to localized access to sheet metal, servo motors, and gluing mechanisms.

The industrial ecosystems in these zones enable streamlined component sourcing, reducing assembly lead times by 20–30% compared to non-specialized manufacturers. Facilities typically integrate CNC machining, laser cutting, and robotic welding lines under one roof, supporting consistent build quality across models. Buyers benefit from scalable output—standard machines are produced within 30–45 days, while customized systems require 45–60 days depending on complexity. Regional clustering also ensures access to experienced technical labor pools and export logistics networks capable of handling heavy machinery shipments worldwide via FOB or CIF terms.

How to Choose Automatic Sweet Box Making Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify ISO 9001 certification as a baseline indicator of quality management. For international buyers, CE marking is essential to ensure compliance with EU safety standards for electrical and mechanical systems. Request documentation for motor efficiency ratings, control panel certifications (e.g., IP54 protection), and material traceability reports for structural components.

Production Capability Assessment

Evaluate supplier infrastructure using the following criteria:

- Minimum factory area exceeding 3,000m² to support dedicated R&D and assembly zones

- In-house engineering teams capable of customizing folding, gluing, and feeding mechanisms

- Integration of precision motion control systems (servo drives, PLCs) for consistent box forming accuracy

Cross-reference online revenue data and delivery performance: prioritize suppliers with ≥98% on-time delivery rates and reorder rates above 30%, indicating customer satisfaction and operational stability.

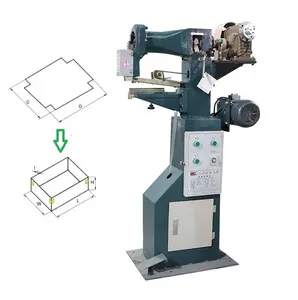

Customization and Quality Assurance

Confirm capability to adjust machine parameters for varying box styles—including rectangular, heart-shaped, and luxury rigid boxes—using interchangeable molds. Demand sample testing under real production conditions to validate glue application consistency, edge alignment tolerance (±0.5mm), and cycle speed (typically 40–80 boxes/minute). Insist on third-party inspection services pre-shipment to verify functionality and safety compliance.

What Are the Best Automatic Sweet Box Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Key Features | Customization Options |

|---|---|---|---|---|---|---|---|---|

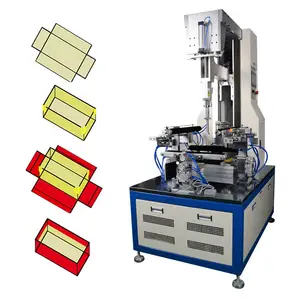

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | US $1,300,000+ | 100% | ≤1h | <15% | $6,000–$148,000 | Fully automatic gift/sweet box forming, V-groove slotting | Color, size, logo, packaging label, graphic design |

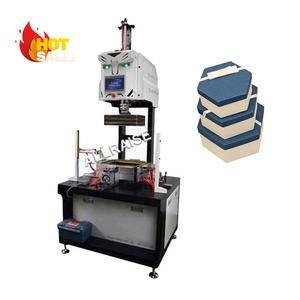

| ZHENGZHOU ALLRAISE COMPANY LTD. | Henan, CN | US $960,000+ | 98% | ≤3h | 39% | $6,856–$14,356 | Rigid box edge folding, special shape heart box capability | Material, size, color, packaging, die-cut design |

| Dongguan Pinchuang Automation Equipment Co., Ltd. | Guangdong, CN | US $730,000+ | 100% | ≤1h | - | $23,000–$103,371 | High-end perfume/sweet box machines, dual positioning systems | Multiple product-specific configurations available |

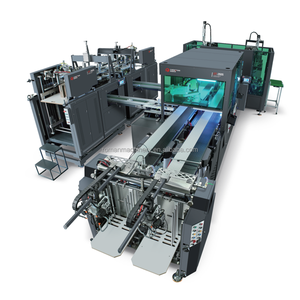

| Guangdong Longxingjian Intelligent Equipment Co., Ltd | Guangdong, CN | - | 100% | ≤4h | - | $10,000–$180,000 | Smart full-auto systems, LS-series luxury food box machines | Advanced automation with IoT integration potential |

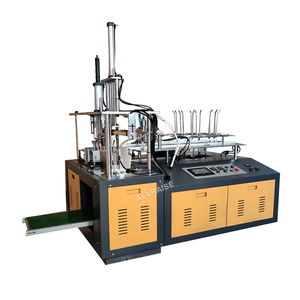

| Zhengzhou Perfect Co., Ltd. | Henan, CN | US $50,000+ | 100% | ≤3h | <15% | $7,000–$33,000 | Diverse container types, die-cutting and hot press functions | Extensive options: mold, material, printing, automation level |

Performance Analysis

Wenzhou Roman and Dongguan Pinchuang demonstrate strong technical responsiveness (≤1h average reply time) and perfect on-time delivery records, ideal for time-sensitive procurement. ZHENGZHOU ALLRAISE stands out with a 39% reorder rate—indicating high customer retention—supported by competitively priced mid-range machines suitable for specialty confectionery packaging. Guangdong-based Longxingjian offers premium smart automation solutions but has longer response cycles; best suited for buyers prioritizing advanced functionality over rapid communication. Zhengzhou Perfect provides broad customization breadth despite lower revenue volume, making it viable for niche or pilot-scale orders.

FAQs

How to verify automatic sweet box making machine supplier reliability?

Audit suppliers through verified certifications (ISO, CE), request factory tour videos highlighting CNC and assembly lines, and analyze transaction history including dispute resolution outcomes. Prioritize those with documented QC processes, such as incoming material inspections and final load testing.

What is the typical minimum order quantity (MOQ)?

All listed suppliers offer an MOQ of 1 set, facilitating low-risk trial purchases. This allows buyers to evaluate machine performance before scaling to bulk acquisition.

Are customization services standard among suppliers?

Yes, all five suppliers provide extensive customization—including box dimensions, material thickness (0.8–3mm paperboard), adhesive type, and branding elements like embossing or flexographic printing. High-end models support modular tooling changes for multi-format production.

What are common payment and transaction safeguards?

Suppliers generally accept T/T, L/C, and platform-backed escrow arrangements. To mitigate risk, structure payments with 30% upfront, 60% pre-shipment, and 10% after successful commissioning. Third-party inspections at origin are recommended prior to final disbursement.

How long does shipping take internationally?

Lead time post-production averages 15–25 days via sea freight to major ports in North America, Europe, or Southeast Asia. Air freight is not feasible for full machines due to weight and size constraints.