Fundamentals Of Metal Machining And Machine Tools

1/17

1/17

1/20

1/20

1/6

1/6

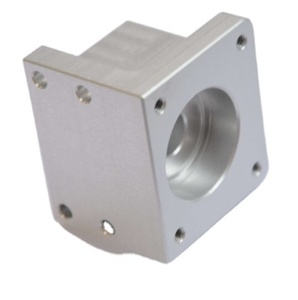

About fundamentals of metal machining and machine tools

Where to Find Suppliers for Fundamentals of Metal Machining and Machine Tools?

China remains a central hub for precision metal machining and machine tool component manufacturing, with key supplier clusters concentrated in Fujian and Guangdong provinces. Xiamen and Dongguan serve as primary production centers, hosting vertically integrated facilities specializing in CNC machining, casting, sheet metal fabrication, and OEM mechanical part production. These regions benefit from mature industrial ecosystems supported by localized steel and alloy supply chains, reducing material procurement lead times by 20–30% compared to offshore alternatives.

Suppliers in these zones offer scalable production capabilities, ranging from high-precision single-piece machining to bulk tonnage orders. The integration of multi-axis CNC systems, automated quality inspection, and lean manufacturing practices enables consistent output across diverse order volumes. Buyers gain access to flexible production models capable of fulfilling both prototype development and serial manufacturing requirements, with average lead times ranging from 15 to 35 days depending on complexity and customization level.

How to Choose Suppliers for Metal Machining and Machine Tool Components?

Selecting reliable partners requires adherence to structured evaluation criteria focused on technical capability, quality assurance, and transaction reliability.

Technical and Production Capacity

Assess suppliers based on demonstrated machining expertise and infrastructure:

- Minimum investment in 3-, 4-, and 5-axis CNC machining centers for complex geometries

- In-house capabilities covering turning, milling, drilling, and precision grinding

- Experience with critical materials such as carbon steel, stainless steel, aluminum alloys, and titanium

- Capacity to handle minimum order quantities (MOQs) from 1 piece to 1 ton, depending on application

Cross-reference product listings with declared processing techniques—suppliers offering end-to-end services (e.g., casting, CNC machining, surface treatment) demonstrate higher integration and control over final quality.

Quality Management and Compliance

Prioritize suppliers implementing formal quality control systems. While ISO 9001 certification is not universally listed, consistent on-time delivery rates above 80% and documented response times indicate operational discipline. Reorder rates exceeding 30%—as observed in top-tier suppliers—reflect customer satisfaction and product reliability. Request inspection reports, first-article testing data, and material certifications for critical components.

Transaction Reliability and Communication Efficiency

Evaluate responsiveness and transparency metrics:

- Average response time under 6 hours (ideal: ≤3 hours)

- On-time delivery performance at or near 100%

- Clear pricing structures with defined MOQ thresholds

Suppliers with verifiable online revenue histories and consistent transaction records demonstrate market validation and financial stability, reducing counterparty risk.

What Are the Leading Suppliers for Metal Machining and Machine Tool Components?

| Company Name | Location | Main Products | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Xiamen Openex Mechanical Technology Limited | Fujian, CN | Machining Services, Casting, Heavy Machinery Bases | 100 kg – 1 ton | $1,500–2,500 | 100.0% | ≤3h | - | - |

| Dongguan Dayi Hardware Products Co., Ltd. | Guangdong, CN | CNC Machining, Automotive Hubs, Fasteners | 1 piece | $0.01–0.15 | 100.0% | ≤6h | 20% | US $2,000+ |

| Xiamen Zhoulifu Technology Co., Ltd. | Fujian, CN | Precision CNC Machining, 5-Axis Processing | 1 piece | $0.48–2.50 | 100.0% | ≤4h | 66% | US $7,000+ |

| DUC HOP MANUFACTURING & TRADING CO., LTD | Vietnam | CNC Lathe Services, Tool Components, Tap & Die | 10 pieces | $4.70–50 | - | ≤5h | - | - |

| Xiamen Fuhongzhou Machinery Co., Ltd. | Fujian, CN | CNC Turning, Milling, Forging, Moulds | 1–100 pieces | $0.12–13 | 80.0% | ≤2h | 36% | US $130,000+ |

Performance Analysis

Xiamen-based suppliers dominate in precision machining and export readiness, with Xiamen Fuhongzhou reporting the highest verified online revenue (US $130,000+), indicating strong market penetration. Xiamen Zhoulifu stands out with a 66% reorder rate and fast response time, suggesting high customer retention and service consistency. Dongguan Dayi offers ultra-low MOQs starting at one piece, making it suitable for prototyping and small-batch production. DUC HOP, while located outside China, provides competitive mid-range pricing for standardized tool components and sheet metal services. Xiamen Openex specializes in large-scale cast foundations and heavy machinery bases, catering to capital equipment manufacturers requiring structural integrity and tonnage-level orders.

FAQs

How to verify supplier capability for precision machining?

Request evidence of CNC equipment inventory, including brand and model numbers of machining centers. Ask for sample inspection reports showing dimensional accuracy (±0.005 mm typical for high-end work). Video audits of workshop floors can confirm claimed capabilities in 5-axis machining or deep-hole drilling.

What are typical MOQs and pricing structures?

MOQs vary significantly: some suppliers accept single-piece orders (common for prototypes), while others require 100 kg to 1 ton for cast components. Unit prices range from under $0.10 for simple turned parts to over $2,000 per ton for large, machined base bodies. Negotiate tiered pricing based on volume increments.

Are samples available before bulk ordering?

Most suppliers offer sampling, though fees may apply depending on complexity. Expect 7–15 days for sample production and an additional 5–10 days for international shipping. Some waive costs for future bulk orders. Confirm whether sample units are functional or cosmetic prototypes.

Can suppliers support full customization?

Yes, leading suppliers provide OEM/ODM services with design input from client blueprints or 3D models. Full customization includes material selection, heat treatment, surface finishing (e.g., anodizing, plating), and assembly integration. Turnaround for custom quotes averages 48–72 hours.

What logistics options are available for global shipping?

Suppliers typically offer FOB terms with coordination support for air or sea freight. For heavy castings or machinery bases, sea freight is standard. Ensure packaging meets international standards for vibration and moisture resistance, especially for precision-machined surfaces.