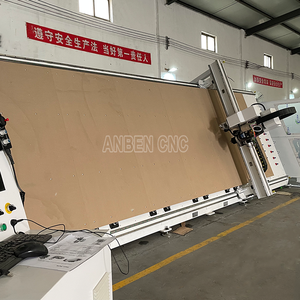

High Quality Ptp Cnc Router Factory

1/16

1/16

1/11

1/11

1/10

1/10

1/3

1/3

1/16

1/16

1/3

1/3

1/9

1/9

1/16

1/16

1/19

1/19

1/23

1/23

1/5

1/5

1/9

1/9

1/3

1/3

1/3

1/3

1/20

1/20

1/5

1/5

1/3

1/3

1/13

1/13

1/1

1/1

About high quality ptp cnc router factory

Where to Find High Quality PTP CNC Router Factory Suppliers?

China remains the global epicenter for high-quality PTP (Point-to-Point) CNC router manufacturing, with Shandong province emerging as a dominant hub. The region hosts a concentrated cluster of industrial suppliers specializing in woodworking automation machinery, leveraging localized supply chains for structural components, servo systems, and precision ball screws. This ecosystem enables cost efficiencies of 20–35% compared to European or North American manufacturers, while maintaining technical parity through standardized industrial design practices.

Suppliers in Jinan, the provincial capital, operate vertically integrated production facilities that encompass frame fabrication, electrical integration, and final assembly. These setups support rapid prototyping and scalable output, with lead times averaging 15–30 days for standard configurations. Buyers benefit from proximity to steel suppliers and logistics networks, reducing material procurement cycles and enabling containerized shipping via Qingdao Port. The presence of mature technical labor pools further enhances production consistency and post-sale service responsiveness.

How to Choose High Quality PTP CNC Router Factory Suppliers?

Selecting reliable suppliers requires systematic evaluation across three core domains:

Technical Capability Verification

Confirm equipment specifications align with operational demands. Key parameters include working table size (e.g., 1325, 2030), axis configuration (4-axis, 5-axis), spindle power (≥9kW), and tool changer type (ATC, linear). Prioritize suppliers offering CAD/CAM compatibility, vacuum hold-down systems, and high-precision ball screw drives. For industrial applications, verify use of heavy-duty cast iron or steel frames to ensure long-term rigidity.

Production Infrastructure Assessment

Evaluate supplier capacity using objective benchmarks:

- Facilities with dedicated R&D teams and in-house engineering support

- On-time delivery performance exceeding 97%

- Response time under 2 hours for technical inquiries

- Evidence of customization capabilities (e.g., control system options, worktable layout, safety systems)

Cross-reference claims with verifiable metrics such as online transaction volume and reorder rates, which indicate customer retention and product reliability.

Procurement Risk Mitigation

Implement transaction safeguards including third-party inspection services prior to shipment. Request detailed documentation on component sourcing—particularly for spindles (e.g., HSD, Huanyang), servo motors (e.g., Yaskawa-compatible), and control systems (Syntec, Mach3, DSP). Utilize milestone-based payment structures to align financial exposure with production progress. Pre-shipment testing should include dry runs and dimensional accuracy checks using calibrated measurement tools.

What Are the Best High Quality PTP CNC Router Factory Suppliers?

| Company Name | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Jinan Spower Machinery Technology Co., Ltd. | Multispecialty Supplier | US $180,000+ | 100% | ≤1h | 54% | $19,000–39,000 | Yes |

| Jinan TechPro CNC Equipment Co., Ltd. | Multispecialty Supplier | US $670,000+ | 100% | ≤2h | 33% | $3,600–18,000 | Yes |

| Jinan Mingpu Cnc Equipment Co., Ltd. | Custom Manufacturer | US $130,000+ | 100% | ≤2h | 16% | $1,999–45,800 | Yes |

| Jinan Forsun Cnc Machinery Co., Ltd. | Custom Manufacturer | US $90,000+ | 94% | ≤4h | <15% | $500–12,250 | Yes |

| Jinan Sudiao Cnc Router Co., Ltd. | - | - | 100% | ≤6h | - | $1,500–40,000 | Limited |

Performance Analysis

Jinan Spower Machinery stands out with the highest reorder rate (54%) and fastest response time (≤1h), indicating strong customer satisfaction and operational agility. Despite lower price points, Jinan TechPro reports the highest online revenue (US $670,000+), suggesting robust sales volume and market penetration. All top-tier suppliers maintain 100% on-time delivery, a critical indicator of logistical reliability. Notably, higher-priced models from Spower and Mingpu target industrial users with advanced features like ATC, CCD cameras, and 5-axis functionality, while budget-oriented offerings from Forsun and Sudiao cater to entry-level workshops. Customization depth varies significantly—Spower and TechPro offer comprehensive configurability, whereas Sudiao’s product range focuses on predefined models.

FAQs

How to verify a PTP CNC router factory’s production capability?

Request facility videos showing raw material processing, welding stations, CNC machining centers, and final assembly lines. Confirm ownership of key equipment such as laser cutters, bending machines, and dynamic balancing testers for spindles. Verified suppliers often provide real-time production updates and allow third-party audits upon request.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity (MOQ) of 1 set, accommodating both pilot purchases and bulk deployments. Lead times range from 15 to 25 days for standard units, extending to 35 days for fully customized configurations with specialized tool changers or extended worktables.

Do PTP CNC router factories support international voltage and language requirements?

Yes, reputable manufacturers offer dual-voltage options (380V/220V, 50Hz/60Hz) and multilingual control panels (English, Spanish, Russian, Arabic). Ensure compatibility is confirmed during quotation to avoid field modifications.

Are samples available before full procurement?

Due to machine size and transport complexity, physical samples are rarely offered. However, suppliers typically provide test-cut videos, digital inspection reports, and remote live demonstrations via video call. Some may offer trial units under consignment terms for qualified buyers.

What after-sales support can be expected?

Leading suppliers offer 12–24 months warranty on core components, including spindle, servo motors, and control system. Remote troubleshooting via TeamViewer or similar platforms is standard. Advanced providers also deliver on-site technician training and spare parts kits to minimize downtime.