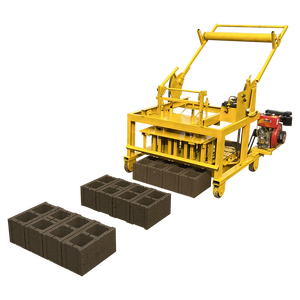

Hollow Block Maker Machine Price

Top sponsor listing

Top sponsor listing

CN

CN

1/13

1/13

1/14

1/14

1/28

1/28

1/16

1/16

1/12

1/12

1/24

1/24

1/25

1/25

CN

CN

1/17

1/17

About hollow block maker machine price

Where to Find Hollow Block Maker Machine Suppliers?

China remains the dominant global hub for hollow block making machine manufacturing, with key industrial clusters concentrated in Shandong and Henan provinces. These regions host vertically integrated production ecosystems that combine raw material processing, hydraulic system integration, and final assembly under one supply chain. Shandong’s machinery sector benefits from proximity to major steel producers and Qingdao Port, enabling 15–20% lower logistics costs for export shipments. Henan, home to over half of China’s construction equipment suppliers, offers mature infrastructure for high-volume manufacturing, supported by a skilled labor pool and specialized component vendors within localized industrial zones.

Suppliers in these regions operate facilities ranging from compact workshops (400–500m²) to large-scale plants exceeding 20,000m², allowing flexibility for both small-batch orders and mass production. The clustering effect enables rapid prototyping, shorter lead times (typically 20–40 days), and cost efficiencies through shared tooling, molds, and testing resources. Buyers gain access to a broad spectrum of automation levels—from manual and semi-automatic models to fully hydraulic, programmable systems—capable of producing blocks up to 40 units per cycle with customizable dimensions, density, and surface finishes.

How to Choose Hollow Block Maker Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical capability, operational performance, and transactional transparency:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for consistent manufacturing processes. For markets in Europe or North America, confirm CE marking compliance to meet safety and electromagnetic compatibility regulations. Request documentation on material specifications, hydraulic pressure ratings (typically 16–25 MPa), vibration frequency control, and mold durability testing.

Production Capacity Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 1,000m² for dedicated production lines

- In-house engineering teams supporting customization (e.g., diesel/electric power options, conveyor integration)

- On-site testing capabilities for mold alignment, compaction force, and cycle time validation

Cross-reference delivery performance data—target suppliers with ≥97% on-time shipment rates—to ensure scalability and reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery technical assistance. Analyze reorder rates as an indicator of customer satisfaction; rates above 50% suggest strong product performance and service support. Conduct video audits to verify claims about production capacity and quality control procedures before placing bulk orders.

What Are the Best Hollow Block Maker Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Product Range | Key Features |

|---|---|---|---|---|---|---|---|---|

| Shandong Hongfa Scientific Industrial And Trading Co., Ltd. | Shandong, CN | Brick Making Machinery, Concrete Mixers, Pallets | 100% | ≤2h | 57% | US $370,000+ | 14+ models | Customization options: block size, color, power source, hydraulic configuration, truck-mounted systems, paver integration |

| Linyi Giantlin Machinery Co., Ltd. | Shandong, CN | Brick Making Machinery | 100% | ≤5h | - | - | 5 models | Full and semi-automatic models; QT4 series; fly ash and cement-based block compatibility |

| Zhengzhou Share Machinery Co., Ltd. | Henan, CN | Brick Making Machinery, Waste Treatment Equipment | 100% | ≤3h | <15% | US $430,000+ | 5 models | Manual, mobile, and semi-auto variants; diesel-powered options; compact designs for small-scale operations |

| Baoding Moheng Trading Co., Ltd. | Hebei, CN | Brick Making Machinery, Concrete Mixers, Hoists | 100% | ≤4h | 50% | US $90,000+ | 5 models | Wide price range; includes fully automatic QT4-25 model; supports mini and mobile configurations |

| Henan Province Gongyi City East China Metallurgical Coal Mine Machinery Factory | Henan, CN | Brick Making Machinery, Crushers, Drying Equipment | 100% | ≤6h | - | - | 5 models | Offers used machines; small-scale electric models; pricing focused on budget segment ($4,000–$6,000 range) |

Performance Analysis

Shandong-based suppliers like Shandong Hongfa demonstrate strong customization capabilities and high reorder rates, indicating robust market acceptance. Their extensive product portfolio supports diverse applications including paving bricks, solid blocks, and silo-integrated systems. Henan suppliers such as Zhengzhou Share Machinery offer competitive entry-level pricing, particularly for manual and mobile units targeting emerging markets. Baoding Moheng stands out with a balanced mix of automation levels and a 50% reorder rate, suggesting effective after-sales engagement. While some suppliers lack disclosed revenue or reorder metrics, their consistent 100% on-time delivery records reflect operational discipline. For high-volume procurement, prioritize suppliers with verifiable customization experience and multi-language technical support.

FAQs

What is the typical price range for hollow block making machines?

Prices vary significantly by automation level and output capacity. Manual models start at $600–$800/set, semi-automatic units range from $2,000–$5,000, while fully automatic hydraulic systems typically cost $12,000–$14,000/set. Custom configurations may exceed $15,000 depending on added features like conveyors or digital controls.

What are common minimum order quantities (MOQ)?

Most suppliers set MOQ at 1 set for standard models. Some offer discounts for multiple-unit purchases (e.g., 2+ sets). Bulk orders can be negotiated for container-sized shipments, often accommodating 2–5 machines per 20-foot container.

How long does production and shipping take?

Lead time for standard machines averages 20–30 days after deposit confirmation. Customized units may require 35–45 days. Sea freight transit times vary: 15–25 days to Southeast Asia, 30–40 days to West Africa, and 40–50 days to South America.

Can suppliers customize machine specifications?

Yes, many suppliers offer tailored solutions including block size (e.g., 400x200x200mm), mold design, power source (electric/diesel), and integration with feeding or stacking systems. Submit detailed technical drawings or functional requirements for accurate quoting.

Do suppliers provide installation and training support?

Support varies by supplier. Leading manufacturers offer remote guidance via video or manuals. Some provide on-site technician deployment at additional cost. Confirm training availability and language support (English, French, Spanish) prior to purchase.