How To Config Tp Link Extender

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/20

1/20

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/1

1/1

0

0

1/3

1/3

1/3

1/3

About how to config tp link extender

How to Configure a TP-Link Extender: Understanding the Supplier Landscape

Wireless networking equipment, including Wi-Fi range extenders like those manufactured by TP-Link, is primarily produced in China’s Pearl River Delta region, where Shenzhen and Dongguan serve as central hubs for electronics manufacturing. This area hosts a dense ecosystem of original design manufacturers (ODMs) and electronic contract manufacturers (ECMs) specializing in consumer networking hardware. The region benefits from vertically integrated supply chains encompassing PCB fabrication, surface-mount technology (SMT) lines, firmware development, and RF testing facilities—all within close proximity.

Manufacturers in this zone typically operate automated SMT assembly lines capable of producing 50,000–200,000 units per month, depending on model complexity. Common components include Qualcomm or MediaTek wireless chipsets, external dipole antennas (for dual-band models), and compact enclosures made from flame-retardant ABS plastic. Most production facilities support both 802.11ac and Wi-Fi 6 (802.11ax) standards, with firmware preloaded to support WPA3 encryption, mesh networking protocols, and mobile app integration. Lead times for bulk orders average 25–35 days, including functional testing and packaging customization.

What Technical and Production Capabilities Define Reliable Suppliers?

When evaluating potential suppliers for Wi-Fi extenders—whether for private labeling or component sourcing—buyers should verify the following technical and operational benchmarks:

Quality Management Systems

Confirm ISO 9001 certification for standardized production processes. For export to regulated markets, ensure compliance with CE (Europe), FCC Part 15 (USA), and RoHS directives governing electromagnetic compatibility and hazardous substances. Suppliers must provide test reports from accredited labs verifying radio frequency performance, thermal stability, and power supply safety.

Engineering and Customization Capacity

Assess supplier capability to support firmware modifications, such as rebranding web interfaces, embedding custom SSID settings, or enabling/disabling specific features (e.g., guest network access). Key indicators include:

- In-house software development teams with experience in OpenWRT or proprietary SDKs

- Access to anechoic chambers for antenna radiation pattern testing

- Support for cloud-based management systems and mobile app integration

Verify that engineering changes can be implemented within 10–14 days for prototypes.

Production Infrastructure Verification

Evaluate physical and technical infrastructure through documented audits:

- Minimum 3,000m² facility with ESD-safe production floors

- Automated optical inspection (AOI) systems post-SMT placement

- Environmental stress screening (ESS) chambers for burn-in testing at 40°C/90% RH over 72 hours

Target on-time delivery performance exceeding 95%, with defect rates below 0.3% (PPM benchmark).

Procurement Best Practices for Wi-Fi Extender Sourcing

Given the absence of publicly listed suppliers in this category under open B2B databases, procurement strategies must emphasize due diligence and technical validation:

Transaction Security and Compliance

Utilize escrow payment terms until product verification is complete. Require sample testing against IEEE 802.11 standards for throughput consistency across 2.4 GHz and 5 GHz bands. Benchmark actual range extension performance in multi-wall environments using packet loss and latency measurements before scaling orders.

Sampling and Lead Time Expectations

Standard sample turnaround ranges from 7–14 days for existing models. Customized units with modified firmware or housing designs require 20–28 days. Air freight shipping adds 5–8 days globally; sea freight remains optimal for container loads (>500 kg), reducing logistics costs by up to 60%.

Customization and MOQ Considerations

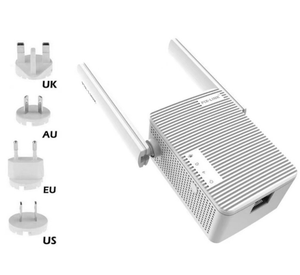

Typical minimum order quantities start at 500 units for standard configurations. For customized SKUs—including branded packaging, localized power adapters, or regulatory label variations—MOQs may increase to 1,000 units. Unit pricing decreases incrementally beyond 5,000 units, with savings driven by batch component procurement and reduced setup overhead.

FAQs

How to verify a Wi-Fi extender manufacturer's reliability?

Request copies of valid ISO, FCC, CE, and RoHS certifications and validate them through official databases. Conduct video audits of production lines and quality control stations. Analyze customer feedback focusing on long-term device stability, firmware update support, and after-sales technical assistance.

What is the average lead time for bulk orders?

Standard production cycles range from 25 to 35 days after confirmation of samples and deposit. Expedited production (within 18–22 days) may be available at a 15–20% premium, subject to line availability and component stock levels.

Can suppliers customize firmware and user interface?

Yes, experienced manufacturers offer firmware rebranding, default setting configuration, and UI language localization. Changes require signed NDAs and technical specifications detailing required features. Prototype firmware is typically delivered within 72 hours for review.

Do manufacturers provide free samples?

Sample policies vary. First samples are often provided at full cost, which may be reimbursed upon order placement above 1,000 units. For repeat customers or high-volume prospects, suppliers may waive fees to secure contracts.

How to initiate a customization project?

Submit detailed requirements including target frequency bands, desired throughput (Mbps), power output (dBm), enclosure material/color, and regulatory marks needed. Reputable partners will respond with feasibility assessments, 3D renderings, and preliminary timelines within 48–72 hours.